This article is also available in Spanish.

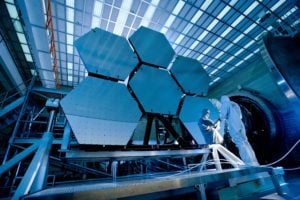

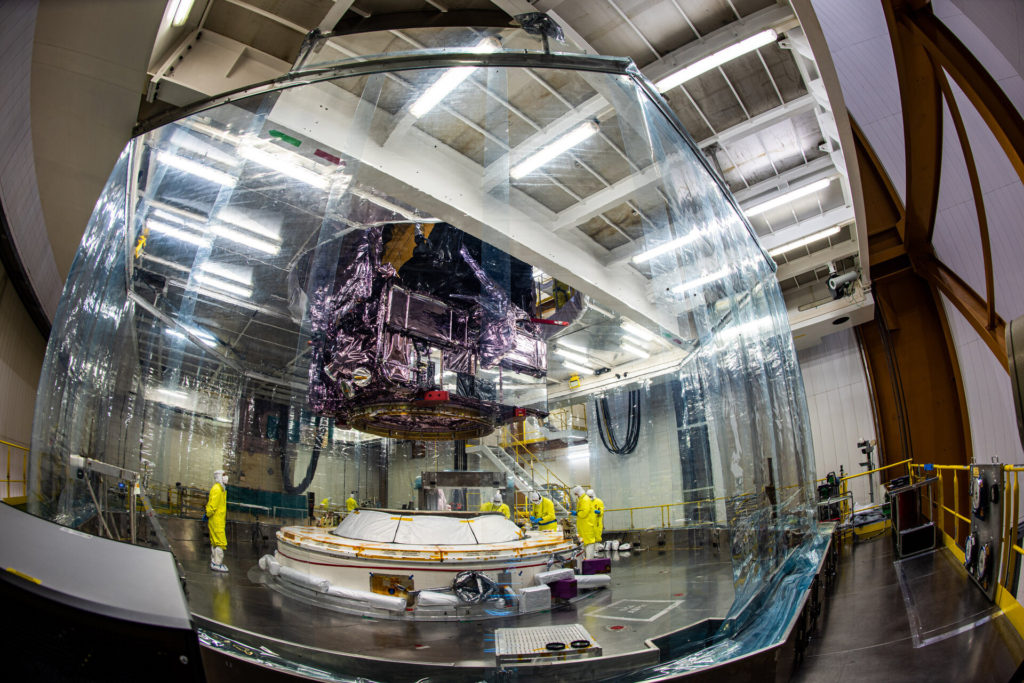

After a two-decades-long collaboration between international public and private sectors, the James Webb Space Telescope launched from Europe’s Spaceport in French Guiana on December 25th, 2021 at 7:20 am. Since its launch, the Webb telescope has been working to capture deeper insight into the early universe, galaxies over time, star life cycles, and planetary systems formations. Webb’s continuing success depends on countless hours of work, innovative ideas, and the latest particle and contamination control technology. The contamination control portion of the Webb telescope played a big role in both its construction and success in orbit. PACs involvement was in the cleanroom planning, designing, and construction processes to help accomplish Webb’s development under strict safety and contamination control protocols.

James Webb Space Telescope

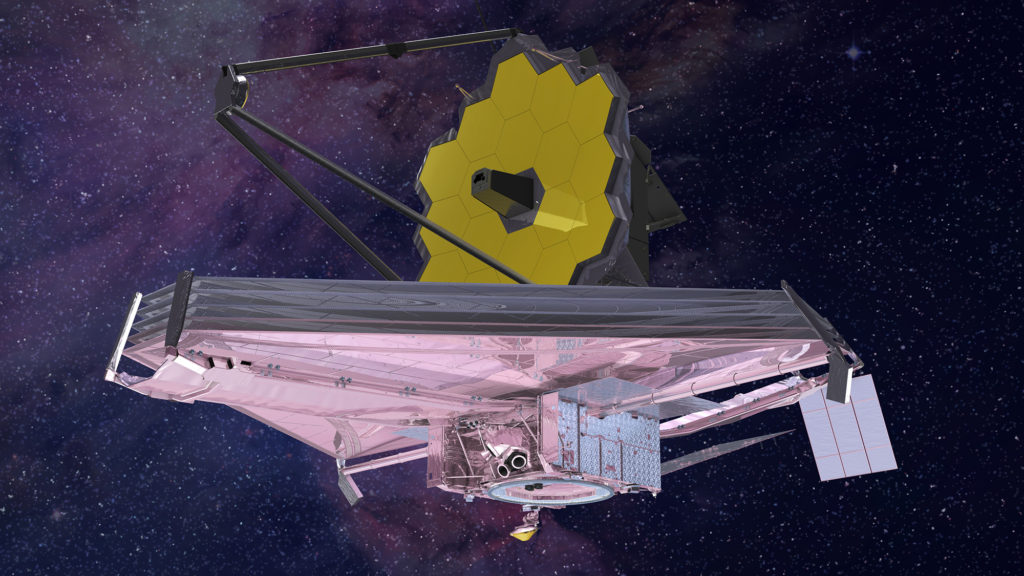

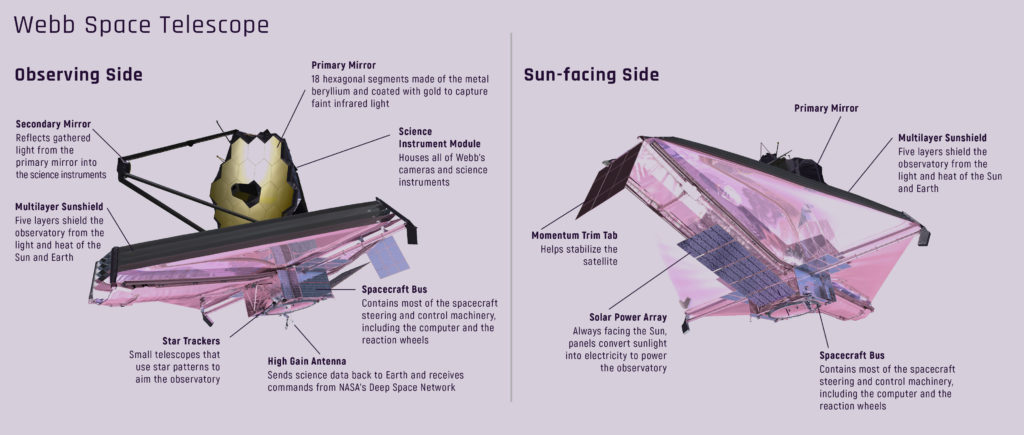

The James Webb Space Telescope, Webb for short, was born from an international collaboration between NASA, the European Space Agency (ESA), and the Canadian Space Agency (CSA). According to the Webb Telescopes’ official website, the telescope is “the world’s premier infrared space observatory of the next decade”. As the largest telescope ever sent to space, Webb can make breakthrough discoveries by detecting infrared radiation from planets, stars, nebulae, and galaxies. Without a doubt, these breakthrough discoveries will help us better understand how these elements form and change over time.

Unquestionably, Webb is the Hubble of the next generation. The telescope confronts its two largest challenges, mirror size, and temperature control, with tennis court-sized sun shields and origami-inspired folding mirrors. For successful observation, Webb consists of four unique instruments:

- Near-Infrared Camera

- Near-Infrared Spectrograph

- Mid-Infrared Instrument with Camera and Spectrograph

- Near-Infrared Image and Slitless Spectrograph

Cleanrooms for Space Telescopes

Cleanrooms play a vital role in protecting a space telescope’s components from outside contaminants like particles, residues, or bio-films that corrode electrical systems, hinder performance, and hamper longevity. Due to the special manufacturing process of space telescopes, the components will go through different phases of construction, each requiring its own cleanroom. Each cleanroom has a unique design, from wall systems to airflow designs, depending on its specific purpose.

Additional Reading: Cleanroom Design for Communication Satellites

PACs Involvement with the Webb Space Telescope Cleanroom

As plans for the construction of the Webb telescope were underway, NASA, the ESA, and the CSA were in need of experienced and proficient companies to provide cleanrooms for the necessary phases. The dedication of PACs seasoned cleanroom experts from the manufacturing phase to installation and validation, leads to successful project outcomes. That dedication led to our involvement in the Webb Telescope project.

How PAC Got Involved

PAC’s involvement with the Webb Telescope resulted from our ability to establish trusting and long-term client relationships. While planning their work in French Guiana, the ESA was advised to utilize PAC’s services by one of our long-term suppliers. With our demonstrated experience and success in spacecraft and satellite projects, coupled with our capacity to work on an international level, NASA, the ESA, and the CSA green-lit our contribution to a cleanroom for one of the construction phases.

Constructing the Cleanroom

PACs cleanroom design was for one of the final phases of the Webb telescope construction. This phase would consist of isolating the telescope for its assembly onto the rocket in preparation for launch.

Once chosen for the project, our cleanroom expert determined the project requirements and sourced the necessary components of the cleanroom. At this point, the final proposal was created and presented to the teams in French Guiana.

The Wall System

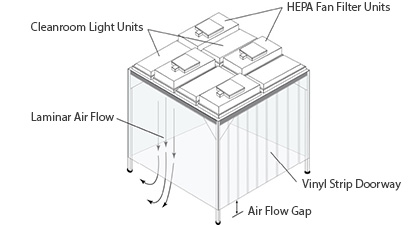

The wall system chosen for this project was a softwall. A softwall cleanroom enclosure is a lightweight tent-like structure that isolates clean or dirty processes. These enclosures are typically made of a metal frame and clear panel walls.

Due to their lightweight and easy assembly, softwall cleanrooms can easily scale up or down to accommodate any potential change in requirements. For Webb, the softwall design provided a contaminant and particulate-matter-free environment for the telescope to be assembled onto the rocket.

The Airflow Design

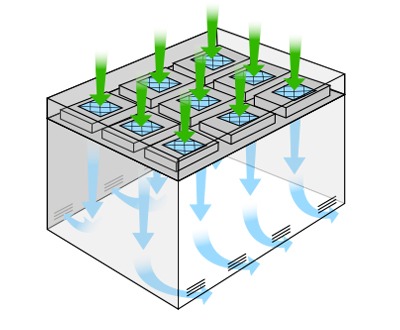

The airflow design chosen for Webb was a single-pass or open-loop air design. Single-pass air flow systems push air through HEPA filters mounted in a ceiling grid system. It works by pulling air from an adjacent conditioned space into the cleanroom. Then, that air exists through near-floor mounted grilles and is not recirculated.

The Challenge

One of the main challenges in this project had to do with the space we had to work with. The space available for the telescope assembly room was minimal. So, our initial process involved some back and forth about design requirements and capabilities. This challenge was one of the factors leading to the softwall decision. Softwall cleanrooms are compatible with smaller spaces and can easily adjust depending on current project needs. Furthermore, their adaptability and flexibility made them the perfect solution to our space constraint challenges. A vital component that aided in the decision of this solution was the support and communication existing between PAC and the team at French Guiana.

The Outcome

PAC’s cleanroom construction for the James Webb Space Telescope was a success. With the help of a PAC cleanroom design, the telescope rocket assembly and its launch into orbit was successful. Since launching, Webb has collected revolutionary images and data on galaxies, planets, and stars and will continue to do so in the foreseeable future. To discover the advantages of working with PAC cleanroom experts, read some of our other cleanroom articles or contact an expert today.

Upgrading or Building a New Cleanroom?

CleanPro®, a division of Production Automation, is a trusted ally of enterprises, research facilities, and government agencies. We leverage 100 years of cleanroom experience to draft, design, schedule, and deliver production ready cleanrooms.

Related Posts

-

Construction Quality Eagle Cleanroom Table: Reviewed

Eagle Group carries some of our most popular and affordable stainless steel table options, from budget grade to specialty marine edge tables.

-

Cleanroom Sticky Mat Frames Now at PAC

The perfect frame for any cleanroom sticky mat. Carpet, concrete, grimy, oily, damp or temporary walkways often yield unreliable or inconsistent adhesion for floor mounted tack mats. Cleanroom sticky mat frames provide a movable base…

-

CleanPro® Cleanroom Installation

Cleanroom Wall System Installation Cleanroom Ceiling System Installation Completed Cleanroom & HVAC Installation Need Help with a Production Ready Cleanroom? PAC cleanroom specialists help you identify which components best suit for your application with respect…

-

A Seamless Cleanroom Construction: PAC Builds a Sterile Environment

Precision is of utmost importance in the complex field of semiconductor equipment manufacturing and achieving perfection starts by establishing a controlled environment. At PAC, we recognize cleanrooms are not merely enclosed spaces; they are meticulously…

-

Cleanroom Construction FAQ

Definitive Cleanroom Construction FAQ: How much does a cleanroom cost? How does the level of ISO classification impact build and operating costs? How much supporting space will I need for a cleanroom addition or ISO…

-

Cleanroom Installation Examples by CleanPro®

Here are some best-in-class cleanroom projects, in which the PAC cleanroom division, CleanPro, provided expertise and turnkey execution for design and installation of cleanroom enclosures, furniture, and components.