Fluid Dispensing Systems Overview

Fluid dispensers are tools designed to control and apply fluids in precise, repeatable amounts. They range from simple syringes to complex, automated systems, catering to diverse applications and fluid viscosities. Choosing the right system can significantly impact efficiency, accuracy, and production quality.

Types of Dispensing Systems

Semi-Automatic Dispensers

- Overview: These systems offer a balance between affordability and control. They typically feature adjustable flow rates, memory functions, and foot pedal or button activation for hands-free operation.

- Advantages: Semi-automatic systems improve accuracy and consistency, reduce operator fatigue, and increase throughput.

- Limitations: They may not be as precise as fully automated systems and require some manual intervention.

Fully Automatic Dispensers

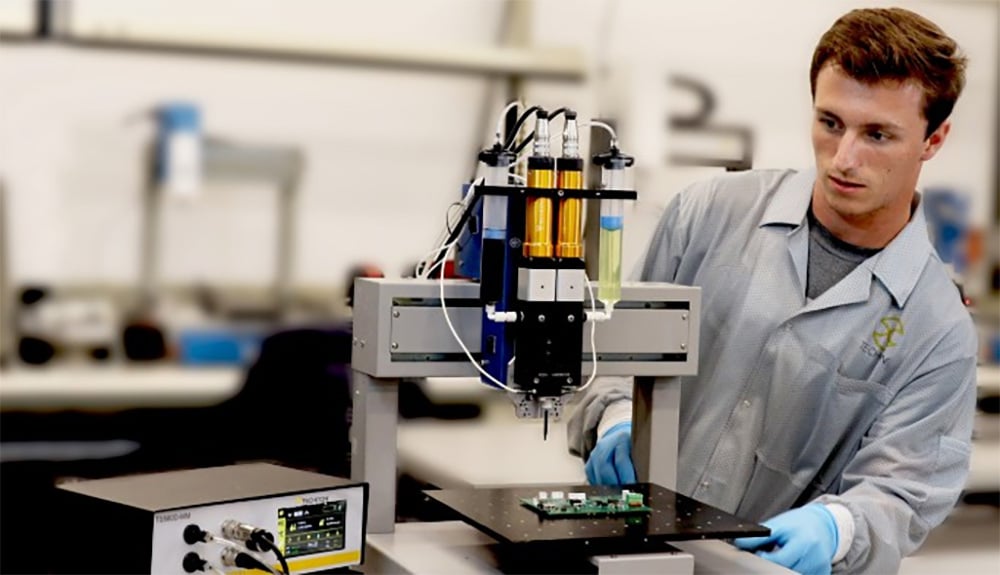

- Overview: These systems are ideal for high-volume, high-precision applications and offer the highest level of control and repeatability. They often integrate programmable controls, vision systems, and robotic arms for complex dispensing tasks.

- Benefits: Fully automatic systems offer unmatched accuracy and consistency, reduce waste and rework, increase productivity, and improve process control.

- Considerations: There is a higher initial investment and the potential for complex programming and maintenance requirements for fully automatic systems. They also may be overkill for low-volume applications.

Additional Products

No matter the type of dispensing system you select, there are a few tools you will need to purchase in tandem, like syringes and tips.

Syringes

Syringes are reusable or disposable and come in various sizes and materials to suit specific fluids and applications. Syringes can also be used without semi or fully automatic systems for infrequent use, providing a more manual way of dispensing fluids.

Tips

Attached to syringes, tips define the dispensed fluid stream size and shape. Tips should be chosen based on the desired flow rate and dispensing pattern.

Key Features to Consider Before Buying

When it comes to choosing the ideal fluid dispensing system for your application, a careful evaluation of your specific needs and the system’s capabilities is necessary. Here is a breakdown of a few key features and crucial factors to consider.

Essential Features

- Precision: This refers to the system’s ability to dispense consistent and accurate volumes of fluid. Consider your application’s tolerance level and choose a system that meets or exceeds your accuracy requirements.

- Fluid Compatibility: Ensure the system’s materials and components are compatible with the fluids you intend to use. Different fluids may have varying chemical properties and require specific materials to avoid corrosion or degradation.

- Dispensing Speed: Evaluate the system’s dispensing speed based on your desired throughput. Consider how quickly you need to dispense fluid and choose a system that can keep pace with your production demands.

- Ease of Maintenance: Regular maintenance is crucial for optimal system performance and lifespan. Look for systems with user-friendly maintenance procedures and readily available replacement parts.

- Integration Options: If you plan to integrate the dispensing system into an automated assembly line, ensure it has the necessary communication protocols and physical compatibility to seamlessly connect with other equipment.

Additional Considerations

- Application Requirements: Identify your specific application’s needs. This includes factors like the type of fluid being dispensed, desired volume and dispense pattern, and any environmental considerations such as temperature or humidity control.

- Budget: Fluid dispensing systems range in price from basic manual options to complex, fully automated solutions. Determine your budget and choose a system that offers the necessary features and performance within your financial constraints.

- Scalability: Consider your future production needs. If you anticipate increased volume or changing application requirements, choose a system that can be easily scaled up or adapted to accommodate future growth.

By carefully evaluating these features and considering your specific needs, you can make an informed decision and select the ideal fluid dispensing system for your application. Remember, PAC’s team of experts can guide you through the selection process and provide valuable insights tailored to your unique requirements.

Fluid Dispensing Systems Available at PAC

At PAC, we understand that selecting the perfect fluid dispensing system requires finding the ideal balance between features, function, and compatibility with your specific needs. Our experts have ensured that we offer a diverse portfolio of dispensing systems from leading brands like Techcon, Metcal, and Jensen Global, each catering to unique application requirements and user preferences. Whether you prioritize precision control, ease of use, or integration flexibility, PAC has the right solution to help you achieve optimal dispensing performance. Let’s take a look at what these brands have to offer.

Techcon is renowned for its innovative fluid dispensing technology. Their systems are meticulously designed and crafted to deliver exceptional control and accuracy, catering to diverse applications across various industries.

Here’s why Techcon might be the perfect fit for you:

- Unmatched Precision and Durability: Techcon prioritizes superior accuracy and long-lasting performance, ensuring your complex, advanced manufacturing needs are met with reliable solutions.

- Decades of Expertise: Backed by extensive experience, Techcon offers transformative dispensing solutions for various sectors, including 5G, aerospace, and medical devices.

- Diverse System Options: Choose from their range of both semi-automatic and fully automatic systems to find the perfect level of automation for your specific requirements.

Metcal has established itself as a leading innovator in benchtop solutions, empowering electronics manufacturers since 1982. Their unwavering commitment to performance and risk mitigation equips you with the tools and confidence to excel in your field.

Here’s why Metcal could be your ideal dispensing partner:

- Top-of-the-Line Performance and Value: Metcal prioritizes exceptional performance and cost-effectiveness, ensuring you receive the tools needed to develop cutting-edge electronics efficiently.

- Mitigating Risks, Maximizing Results: Their solutions are designed to minimize risks and maximize return on investment, providing peace of mind and driving positive outcomes.

- Expertise in Electronics Assembly: Metcal possesses an in-depth understanding of the electronics assembly industry, offering targeted solutions for applications in aerospace, medical devices, and consumer electronics.

Jensen Global stands out as an industry leader in industrial dispensing systems, supplies, and comprehensive solutions. Their 30+ years of experience translate into a deep understanding of diverse dispensing needs, allowing them to offer:

- Unwavering Commitment to Quality: Their focus on exceeding customer expectations extends to every step of the journey, from initial interaction to product delivery and comprehensive service. Since the beginning, Jenson Global has created and sold its products with a customer-first mindset that puts your needs and unique applications first.

- Wide Product Range and Expertise: Jensen Global offers a vast selection of dispensing systems and supplies, catering to all types of dispensing needs. Their expertise allows them to address even the most unique application challenges. From electronics and aerospace to art and life sciences, Jensen Global provides dispensing solutions for customers of all sizes.

Related Posts

-

Metro Shelving Accessories Buyers Guide

View the Metro shelving accessories buyers guide. We've compiled the entire collection of Metro accessories onto one page for your convenience.

-

Dispensing: Recycle or Replace?

The most popular dispensing technique used in the manufacturing process is time and pressure dispensing (TPD) from a syringe barrel. This method became popular because if the low-cost, simple setup and lack of required maintenance.…

-

Helpful Tips for Choosing Entryway Mats

Entryway mats are key to keeping your floors clean and safe. Here are several things to keep in mind when buying an entryway mat. The first thing to consider, where will the mat be located? There are…

-

Sticky Mat Installation Guide - Placement Tips

Through CleanPro® adhesive sticky mats were designed to be used for cleanroom environments, they can be used wherever there is a need to trap contaminants or simply keep an environment cleaner. They are excellent for…

-

Permabond Anaerobic Adhesives & Sealants

For Threadlocking, Pipe Sealing, Gasketing, and Retaining By definition, anaerobic adhesives remain liquid until isolated from oxygen in the presence of metal ions, such as iron or copper. For example, when an anaerobic adhesive is…

-

Wearwell Chemical Resistance Guide

Key A = Performs Well B = Slightly Affected C = Moderately Affected D = Highly Affected U = Not Recommended NT = Not Tested Chemical Urethane Nitrile PVC CFR SBR Natural Rubber Acetone U…