Table of Contents

Why Get Help Building A Cleanroom?

Cleanroom construction, much like building a new facility, requires a myriad of workers, parts, materials, and design considerations. Sourcing components and supervising construction for a new facility is not something you’d ever take on by yourself. Why would building a cleanroom be any different?

How Much Does a Cleanroom Cost?

Cleanrooms are like race cars. When properly designed and built, they are highly efficient performance machines. When poorly designed and built, they operate poorly and are unreliable.

A short-hand cleanroom cost estimate should leave a buyer weary, as should an estimate far below market price. Estimating the true cost of a cleanroom requires preliminary engineering and computing. Imagine a wedding planner providing the cost of a wedding without considering the number of guests, the cost of the venue, or accommodations for food and music?

What is the Greatest Cleanroom Cost Factor?

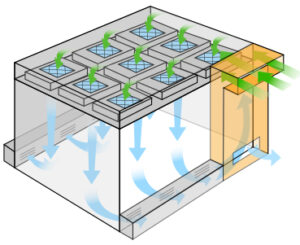

The cost of cleanroom varies dramatically based on size, application, and compliance requirements. Generally, cleaner spaces require more air changes per hour (ACH). Higher volumes of air require expanded HVAC and design considerations, thus expanding cost. The ambient temperature and humidity of the space also have cost implications. Beyond size and cleanliness, accommodation for critical applications also expands cost. Sterile compounding or hazardous drugs require acute controls for room pressurization. These applications require multiple cleanroom segmentations with cascading room pressure. In summary, gauging the cost of a cleanroom is nearly impossible without determining its size and compliance requirements.

How Does the Level of ISO Classification Impact Build and Operating Costs?

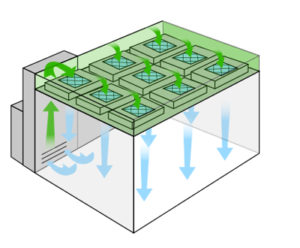

Each ISO Class level is 10 times cleaner than the next lowest classification. Moving up one cleanroom class from an ISO Class 8 to an ISO Class 7 cleanroom requires nearly twice as much air. Air filtration and conditioning is a significant factor in overall operating expenses. Overall square footage, the number of filters required, humidity, and air intake temperature all impact energy use. The efficiency of these systems is a direct relation to operating cost. A cost increase of 25% for each step in classification is expected. Generally, a recirculating airflow cleanroom incurs a larger initial investment, but is more efficient than a single pass cleanroom design.

Cleanroom Components: Wall Panels, Filters, Pass Throughs, Air Showers?

Are you a cleanroom contractor looking for pricing on components? We sell specialized construction materials, ala carte. Browse our online catalog or request a quote for any of our wall panels, ceiling grids, fan filter units, pass-thrus, air showers, monitoring solutions, and more.

What’s the Advantage of a Turnkey Cleanroom System?

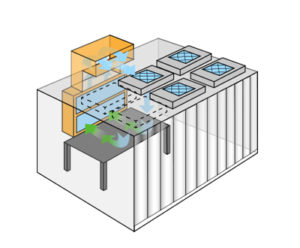

Cleanroom control systems and electrical designs are critical, but so are considerations for structural, architectural, and application compliance. Turnkey cleanroom solutions with modular components empower easy adaptation of adjacent structures, cascaded classification of interior rooms, expandable compliance, and relocation.

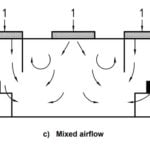

What are the Most Popular Cleanroom Air Flow Designs?

When Should I Choose a Hardwall Cleanroom Design?

Hardwall cleanroom wall panels and components provide a self-supporting environment that stands as a load-bearing structure. Extra-high wall panel systems can accommodate large equipment over the standard 8’ height.

What’s the Advantage of CleanPro® Installed Cleanroom System?

Our team of engineers and cleanroom experts bring your cleanroom to life through dedicated partnerships with world leading cleanroom manufacturers and vendors. CleanPro® turnkey cleanroom services consolidate cleanroom planning, design, engineering, construction, assembly, and certification into a single point of contact. CleanPro® is not limited to just one set of components or style of construction, so we always arrive at the best choice for our customers. Our engineers and specialists have over 100 years of combined experience in cleanroom planning and installation. See some cleanroom construction examples.

Are CleanPro Installations Limited to U.S. Locations?

CleanPro is a division of Production Automation Corporation. (PAC) Our network of warehouses and installation partners include locations in the United States, Mexico, Costa Rica, Dominican Republic and the rest of Latin America. Sí, hablamos español.

What if I Don’t Need a Cleanroom Classification & Want to Isolate a Clean Area?

Many cleanroom service providers only want to work only on a turn-key basis. CleanPro is a resource for cleaner futures, no matter the size or scope of the project. We’ve helped many industrial customers who are not necessarily targeting a specific cleanroom classification, but are simply trying to isolate an operation to keep it cleaner. The CleanPro network provides support, construction, and outfitting of almost any type of critical or clean space environment. Its engineering and support teams have facilitated best in class cleanrooms, furniture, and supplies for many government and enterprise organizations.

Want More Info on a Cleanroom for Your Specific Application?

We help industrial, government, and enterprise customers target a specific cleanroom classification, or isolate an operation to keep it cleaner.

Related Posts

-

Medical Device Cleanroom Construction Part 1: Walls and Installation

How is a medical device cleanroom built? Here's a component-by-component guide to ISO Class 7 cleanroom construction.

-

CleanPro® Turnkey Cleanroom Install

CleanPro’s turn-key cleanroom solution provided a one-stop, one-contact result for the initial delivery and on-site installation of walls, ceiling grids, electrical systems, flooring, filters, HVAC, and more.

-

Medical Device Cleanroom Construction Part 2: Doors, Electrical, and Layout

In medical device cleanrooms, a common configuration is an ISO 8 gowning room and ISO 7 primary production area. A cascading air flow design and positive pressure HVAC calibration move the cleanest air at the…

-

Medical Device Cleanroom Construction Part 3: Fan Filter Units - Ceiling Grids

In this post, we overview technical considerations for clean room fan filter unit selection, installation, and features. You'll learn how PAC approaches design and configuration of cleanroom HEPA filter units and fan filter housing specifications.…

-

Guide to Remote Particle Counters and Air Quality Monitoring Systems

Learn about the newest WIFI & IOT enabled air quality monitor features. Remotely monitor indoor & outdoor air quality including PM2.5 - PM10 particles, dust, C02, & VOCs.

-

Gowning Room Design – Guidelines, Anterooms, and ISO Classification

A gowning room has many variables. There is no mathematical formula when determining the features, surfaces, and HVAC requirements best suited for your application. Space requirements, volume of operators, aseptic workflows, material choice, and even…

-

USP 800 Cleanroom Construction Hazardous Compounding: Options and Alternatives

There are a few options available to cleanroom facilities who require new upgrades for USP 800 compliance. The best option will depend on the variables of the facility and cleanroom in question. Option A: Convert…

-

USP 800 Cleanroom Design - Negative Pressure Changes and Requirements

What equipment and engineering controls do USP 800 cleanrooms require? What types of storage and monitoring systems will I need?

-

USP Posts Revised PDFs for USP 795, 797, 800, 825 - Updated November 2019

Updated November 2019: Where can I find updated USP 800, 797, and other compounding documentation? Are there any recent changes to USP documents? When is the official deadline for USP 800 compliance?

-

The Truth about Cleanroom Air Change Rates, Charts & Methods of Calculation

Why Can't Anyone Agree on Benchmarks for Cleanroom Air Change Rates? There are a number of best practice guides and benchmarks for cleanroom air change rates (ACR). Many of which reference charts dating back as…