Table of Contents

In the last three decades, “smart” air quality devices have made their way to manufacturing floors and cleanrooms, but also to parallel production spaces.

Today, local communication protocols such as Bluetooth, Zigbee, JSON, and other communication links provide onboard capabilities for syncing environmental monitoring and testing tools with Cloud connections. These particulate and air quality sensors are now available in handheld and remote units which empower real-time adjustment, remote monitoring, and data visualization.

Handheld particle monitors are a growing trend helping manufactures spot-check and identify contamination in real time without large capital investments on dedicated monitoring systems. Plug and play software integration allows multi-facility testing with easily recalled presets for tracking and recording data across dozens of cleanrooms, packaging areas, or parallel workspaces.

What to Look for When Purchasing a Particle Counter?

Generally, cost structure reflects the number of channels, air flow rate, laser power, smallest channel size, particle threshold, and processing speed.

- How fast, how many, and what size particles does it measure?

- Do I need a remote system or a handheld one?

- Or, do I need an inline system connected to a central data hub and monitoring software?

- Which type of unit is the most appropriate for a single facility, or contrarily, an enterprise that spans dozens, if not hundreds of locations across the globe?

- How will I organize, access, and report this data?

- Are additional sensors like VOCs, RH, and CO2 levels important benchmarks for my needs?

- Is battery life important?

These are all important questions, each prioritized by risk assessments, return-on-investment, and industrial benchmarks. But can’t we just consolidate all of these questions?

Connecting IOT to the Next Generation of Particle Counters

The Internet-of-things (IOT) is a series of internet connected air quality monitors that aggregate disparate inputs or sensors from many sources, whether across the room or across the globe. These tasks seemed largely impossible in decades previous.

In some cases, a series of wirelessly connected devices may replace thousands of individual sensors and miles of cables and wiring. Instead of mulling over screens and reports in a master control room, operators can now seamlessly review, monitor, graph, and make annotations out in the field using a smart device’s browser.

Particles Plus air quality monitors send communication protocol through cloud services, or any server configured for JSON data and reporting. JSON stores information in an organized format readable by machines and humans, much like an Excel file. The JSON configuration interface allows parameters for data types, frequency, and project structure.

One of Few Multi-Processed Particle Counter CPUs

Each of the 6 multi-processed channels are computed in parallel and simultaneously adjustable for targeting user-selectable, size-specific particles and alarm thresholds. Users select data for reporting, such as which sensor values, when to send, and finally to whom. The data moves with you: SMS configuration allows alerts or reporting to specific and multiple mobile devices with unique data reports when using an online cloud service like IMS-RT.

Why Speed Matters

Processing rate and calculation speed are important in fast moving assemblies, or under fast moving and turbulent air conditions. Most particle counters suffer from analog to digital conversion time, with delays processing a single particle anywhere from 5 to 100 microseconds, where they are blind to any other particles in that time period. The Particles Plus advanced processing with a dedicated 32 bit processor just to count the particles avoids this problem providing for a more reliable, accurate particle counts. This also allows for the Particles Plus optical particle counters to be used outside of the cleanroom in more industrial applications such as environmental investigations, post remediation clearance testing and industrial health and safety applications for monitoring particulate matter (PM).

Particles Plus has been able to shrink this latency cycle to just 4 micro seconds, allowing a much more precise evaluation of fast-moving processes when spot checking and monitoring in real time.

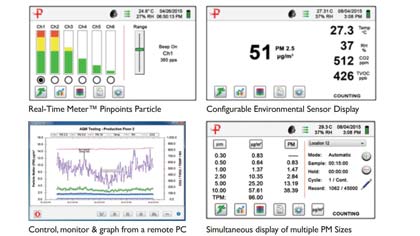

Real-Time Display, Plug & Play with No Extra Hardware

Remote operation, remote configuration, and real-time data graphing let you monitor air quality and particle counts from any computer, or via the onboard display. Changes to flow rate, sample ranges, and alarm systems are all monitored and adjustable from a remote laptop or desktop using their included IMS software. W

ith their industry’s first remote diagnostics capability this allows the user to connect the instrument through their PC directly to a Particles Plus Technician who can retune or correct any improper configurations, or trouble shoot any warnings. Units have generally small variations in out-of-box features. The most significant differences are the choices between an internal or external air pump, smallest channel size, additional C02/VOC sensors, and handheld vs remote versions.

Electronic hardware and software architecture must be a critical focus during particle monitor design stages. This is one reason that we recommend Particles Plus particle counters and air quality monitoring instruments.

All Particles Plus instruments interface directly with a PC, Ethernet, and internet connection. Wi-Fi is onboard without any external add-ons or accessories. Additional (optional) interfaces are available and required for Modbus RTU and older RS485/RS-232 systems, but easily integrated at time of manufacture.

Set Specific Alarms for Multiple Sensors

The cloud-based monitoring software and the instrument’s interface provide a latching alarm indication for event alarms and for fault reporting. The reporting can be done with user defined contacts using SMS data text messaging, as well as email notifications. This can be programmed to report by sensor, or it can be more detailed by reporting notifications and alarms to different individuals by specific channels or parameters within a single instrument.

The reporting capabilities, onscreen graphing by sensor, or multiples of sensors, and access to data from any point in time that has been saved makes access to information about a facilities air quality easy and readily available wherever a browser can be opened without expensive client software seats.

Count Viable and Non Viable Particles

In recent years, hospitals and compounding pharmacies have required improved testing for cleanliness under updated USP 797 and USP 800 guidelines. They must certify their cleanrooms are in fact clean, and not causing risk of infectious diseases through negligence or poor practices.

Official validations for pharmaceutical cleanroom particulate counts are usually conducted by external service firms every 6-12 months. However, a handheld unit allows continuous checkups, whether as needed, continuously, or when a glove sample fails microbial testing. In the case below, you’ll see how alarm settings provide faster response times by identifying an exact location of compliance failure.

A hospital that was passing their non-viable particle counting during their biannual certification process yet were failing for their viable particle testing. The hospital struggled to discover the cause of the non-compliance looking at gowning practices, and other housecleaning practices, that did not improve their cleanrooms performance. Using the Particles Plus 8306 handheld particle counter, with a its Real-Time Meter feature discovered the source of the contamination indicated the facilities HEPA filtered air supply system. The video above was taken on location and provides a detailed visual display of how the feature works in the field.

The Big Picture

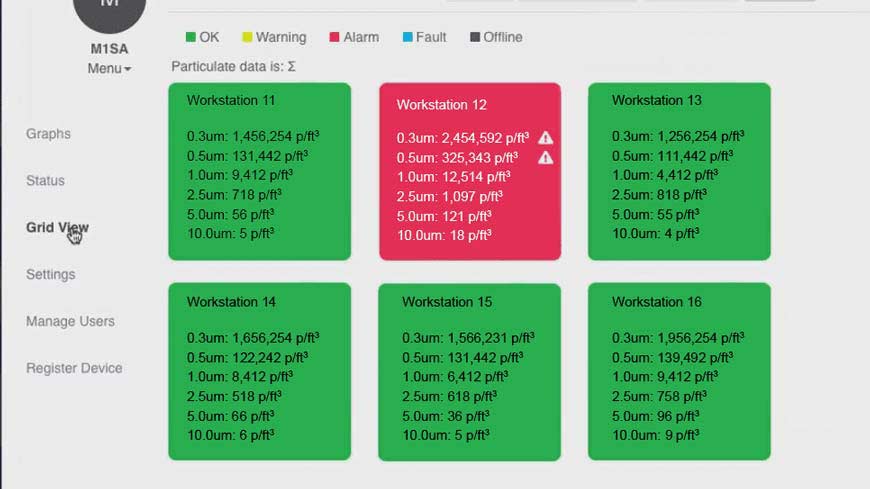

The optional IMS-RT cloud-based software interface is intuitive and easy to navigate. The grid view provides a full dashboard by company, facility or room, displaying multiples of sensors and allowing for quick visual cues onscreen of an event that requires action. The event can then be drilled down to provide even more data related to that sensor and that location.

Monitor Air Quality in up to 1000 Unique Locations

- Monitor offices, cleanrooms, production floors, auxiliary spaces.

- Providing real-time data on events that could affect product or quality of life

- All Particles Plus counters meet ISO 21501-4 and JIS B9921.

- Stores up to 45,000 sample records, 1,000 sample locations, and 50 user defined sampling recipes

- Connect using Ethernet, USB or (optional) Wireless 802.11 b/g, RS485 or RS232

Count Particles, VOCs, CO2, Temp & RH

- All Particles Plus instruments offer indication of Mass concentration in μg/m³ and an indication of PM (Particulate Matter)

- 6 channels of simultaneous PM data versus single size readings from most photometers.

- CO2, Temperature and Relative Humidity with user alarm set-points

- Measures TVOC in parts per billion (Model Model 7302-AQM and 5302-AQM)

Indoor Air Quality Monitoring

- Monitor multiple, simultaneous PM size channels.

- No need for additional impactors or multiple instruments

- Ideal for fixed system ventilation rate monitoring

- Particulate, temperature, humidity, CO2 and TVOC monitoring

- Internet of Things protocol allows remote access and cloud-based monitoring services

- Push real-time data to the cloud where sensor outputs can be visualized by the general public and downloaded by users and researchers.

- Real-time data on events that could transform the quality of products or quality of life for their organization or the occupants

Particles Plus Remote Monitoring Systems

This remote particle counter stores up to 45,000 time stamped particle count and environmental data records which provides data redundancy on every instrument. Particles Plus counters can be controlled or the included Instrument Management Software.

Cleanroom

- Provide a latching alarm indication for event alarms and for fault reporting.

- Air quality easy and readily available wherever a browser can be opened without expensive client software

- Collect data from a few to hundreds of sensors for storage and real-time monitoring

- Retrieve dashboard views and downloaded for later reporting,

- In the event of total system failure, the software and client data are backed up and stored weekly in secure cold storage facilities for restoration with available IMS service.

- Easy to clean and wipe down with minimal particle traps

Particle Plus Handheld Laser-Optical Particle Counter

The Model 8303 or 8503 Handheld Particle Counter is easy to configure, this instrument displays up to 3 user-selectable size channels as well as (optional) temperature and relative humidity. View data and generate ISO 14644-1, EU GMP Annex 1 or FS 209E reports. Export to Particles Plus data-software. The 8303 also has a mass concentration mode that approximates density in μg/m3.

Particles Plus counters can be controlled and monitored remotely via web browser. The 8306 & 8506 has a mass concentration mode that approximates density in μg/m3.

Environmental & Traffic Air Monitoring

- Provides additional context for interpreting/understanding sensor response and improving source attribution.

- Data recorded by each Ambient Air Monitor node is stored on an internal non-volatile memory at user-defined data acquisition rates (1 second to 99 hours).

- Measurements provide a near-instantaneous look at changing pollutant concentrations.

- Integration of peripheral sensors for measurement of environmental parameters (relative humidity, temperature, barometric pressure, CO2 and TVOC)

- Rugged weatherproof enclosure with versatile mounting options

- Distributed sensing solutions capable of 10 to 100 times the spatial and temporal resolution of typical air quality monitoring (AQM) networks

- Call for Details

Model EM-10000

Integration of peripheral sensors for measurement of environmental and meteorological parameters (relative humidity, temperature, solar intensity, barometric pressure, ambient noise, wind speed & direction) provides additional context for interpreting/understanding sensor response and improving source attribution.

- 0.3 – 25 μm (across 6 size bins)

- Electrochemical measurements of [NO, NO2

- Ox (O3 + NO2 ) + CO2

- Non-dispersive infrared (NDIR) measurement of CO2

Wearable Vacuum Pumps for Active and Remote Operators

- Hands-free air quality monitoring to the field. LED display and efficient battery

- Up to 30 hours of continuous air sampling to customer provided impactor, cyclone or filter cartridges

- Conservation mode extends charge cycles with a 00:30 idle timer for power as needed.

- Belt clipped air samplers provide a non-intrusive unit for active use.

- For example, at a remote mining site or during a sprawling wildfire.

- Call for Details

Air Sampler 1000 Series

Small in size, simple to use and easy to operate, the Air Sampler 1000 Series is ideal for personal sampling applications. Only weighing 0.70 lbs. this provides a flow range between 1000 – 3000 ml/min.

The 1000 Series allows for constant flow correction even with changes in ambient temperature and barometric pressure through our ultra-quiet rotary vane vacuum pump technology.

The easy to read LED display provides accumulated sampling volume and a battery conservation mode after 30 seconds of idle use allowing for over 30 hours of continuous sampling.

The power switch allows for easy operation including Continuous Sampling, Volume Reset and Battery Conservation Mode, with the push of a button.

Related Posts

-

New: Particles Plus Cleanroom Particle Counters and Air Quality Monitors

Cleanroom particle counters and anemometers offer portability, accuracy, and easy use. The self-contained devices allow local and off-site testing of air quality, air speed, HVAC efficacy.

-

How to Choose the Right Cleanroom Particle Counter

Cleanroom particle counters differ widely based upon particle threshold, cost, and features. How to do you determine if you need a particle counter or what model of particle counter to purchase? In this article we…

-

What Is A Particle Counter? How Do Particle Counters Work? What Are They Used For?

How Do Particle Counters Work? What's the Difference Between a Condensation Particle Counter and An Optical Particle Counter?

-

2019 Cleanroom Trends: Static Control, Process Monitoring, and Quality Control

Trends in the cleanroom market: reducing production costs, improving environmental conditions, and extending customer support with expertise.