Particle Counters Monitor Fine Particulates for Cleanroom Manufacturing, Sensitive Production, and HVAC Systems

Airborne particle counters play a crucial role in monitoring, classifying, and diagnosing the source and complexion of contaminants in cleanroom operations. Manufacturers of semiconductors, flat panel displays, and hard disk storage units have long recognized the relationship between improved air quality and the increase of final yields. Specifically, the control of air borne particles is essential in achieving ISO Class certification of clean rooms, zones, and spaces. Because work spaces change with production demands, access to localized monitoring equipment is essential for measuring and maintaining desired levels of cleanliness.

Electronics manufacturing requires strict procedural and environmental controls, especially when processes require toxic, flammable, corrosive, or reactive materials. In parallel, processes and people introduce and generate particulate throughout a production session. Yields drop dramatically when components interact with dust, airborne microbes, aerosol particles, and trace moisture. Particle counters ensure that cleanroom machinery and design features, such as air filters and passthroughs, function effectively during production and at rest.

Depending on the size of the particles of interest, different instrumentation provides varying levels of capabilities. The extent of particle counters sensitivity to particles differs based upon application and thus design features that detect and count particles.

What's the Difference Between a Condensation Particle Counter and An Optical Particle Counter?

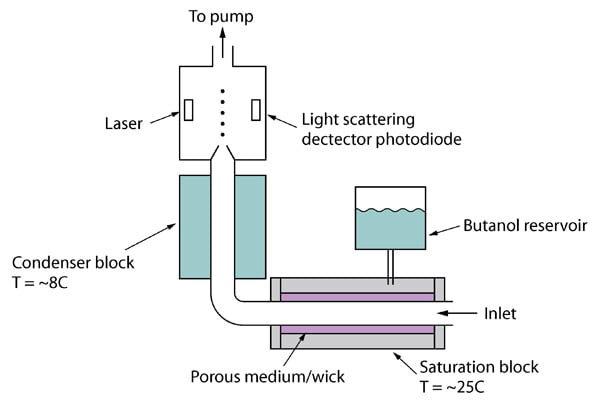

A Condensation Particle Counter (CPC), sometimes referred to as a Condensation Nuclei Counter (CNC) measures ultrafine particle concentrations undetectable by photometers or OPCs. A cartridge insert holds a high-purity liquid, usually reagent grade isopropyl alcohol or butanol which is applied to incoming air samples. When the particles and the liquid interact, nanoparticles expand to a size of approximately 10-12 um, therefore allowing easier detection. The process is known as homogeneous nucleation. CPC particle counters achieve an ideal saturation value, normally of 100-200%, by closely regulating the saturation levels as they fluctuate with temperature. The more uniform the saturation, the more accurately the CPC can detect individual variance pulses of light scattered by passing particles. Inhomogeneous and/or non-circular particles contribute to misguided or downright deceiving test results, highlighting a scenario where CPCs find favor over standard optical particle counters. Standard optical particle counters lack the sensitivity to record particles at a threshold of roughly 50nm. Condensation particle counters count all particles down to 1 nm, depending on the model. On the other hand, CPCs cannot provide data on the size of particles, they can only count them.

Uses and Common Applications for Condensation Particle Counters:

- Respirator fit testing

- Filter testing

- Indoor Air Quality Studies

- Evaluation of mechanical filtration systems

- Point source monitoring

- Validate engineering or process controls

Light Scattering Airborne Particle Counters

How Light Scattering Airborne Particle Counters Work (LSAPC)

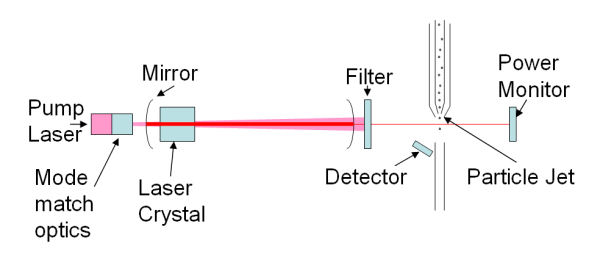

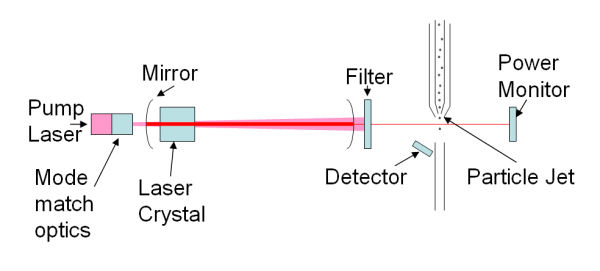

Light scattering particle counters are one of the most common designs used for air quality monitoring and classification in cleanrooms. Also known as optical particle counters, measure particle number concentrations and size range to validate mechanical filtration system and identify sources of contamination. When a particle passes through a beam of light, the light scatters. Optical particle counters don’t directly indicate the size of a particle directly. Instead, they measure the diameter of the light scattered and suspended in air. Particle size, also called particle diameter, is measured after a photon detector converts the size and frequency of scattered light into electrical signals. Useful measurement and data require quality optical design and a high powered laser with precision angles. Intracavity OPC designs (shown below) improve the intensity of the laser beam by amplifying radiation upwards of 100x.

Different Types of Cleanroom Particle Counters

Hand-held particle counters are a small & portable, self-contained device easily transported for use with testing, HEPA filters, laminar flow hoods and clean benches. They detect and count physical particles as small as 0.3 microns up to 10 microns. Handheld systems provide a convenience that captures data locally, which is indexed by a built-in display screen. Price is often determined by particle size capabilities, the number of air inflow channels, and added features such and air temperature, Wi-Fi connectivity, sample capacity, and humidity readings.

Benchtop portable particle counters feature a larger color touch screen, streamlined, user-friendly interfaces and pre-programmed standards mode to guide you through the measuring and certification process. Benchtop models handle a higher volume of air flow than hand-held units and provide a more dedicated solution for long-term monitoring and certification.

Remote particle counters are used to continually monitor airborne particle levels in real time. They do not have a built-in display and are connected to a facilities data acquisition system to monitor the overall cleanroom performance.

The Smart Features We Like from Particles Plus Air Quality Monitoring Instruments

Local communication protocols such as Bluetooth, Zigbee, JSON, and other communication links provide onboard capabilities for syncing environmental monitoring and testing tools with Cloud connections. These particulate and air quality sensors are now available in handheld and remote units which are controlled from web browsers or on-board display. Learn more about how these particle counters allow real-time adjustment, remote monitoring, and data visualization.

What Are Particle Counters Used For?

- Testing for air filter leaks

- Spot checking real time cleanliness during operation

- Root out contamination

- Testing for filter leaks and efficiency

- Creating standardized testing routine for long-term monitoring and data logging

Monitoring VS Classification

Cleanroom classification and cleanroom monitoring differentiate cleanliness factors between two types of controlled settings. Classification focuses on the environment free of human interaction or occupancy. Monitoring accounts for circumstances when the variabilities of people and processes are applied to a clean space. Classification is a standardized procedure executed with uniform or homogeneous particle counts in a room or zone. Monitoring is a dynamic process which creates data and unique samples from zones and sample maps determined by a need for rapid understanding, trend info, or troubleshooting. For the scope of this article, we’ll focus on cleanroom monitoring with hand held particle counters, as opposed to classification specifications or 3rd party certification processes. Learn more about cleanroom classification here.

Environmental Monitoring VS Process Monitoring

For electronics manufacturers, process and environmental monitoring are not required by regulation, but instead as a way to reduce the risks of contaminants thwarting yields and quality control. Process monitoring determines the readiness of the room to execute a task.

Pharmaceutical manufacturers face more strict guidelines for environmental and process monitoring. Normally, handheld particle counting equipment is not feasible for testing ISO Class 5 specifications required in many pharmaceutical cleanroom facilities. Dedicated installations of centralized particle counters, known as “remote” air particle counters, are attached to walls, equipment, or fixtures for long-term, dedicated monitoring.

What Size Particles Are Monitored for Electronics Manufacturing?

For each environment, the requirements for particle detection changes with the application. Routinely, the particle size is monitored by different electronics manufacturers is as such:

- Semiconductor manufacturing: 0.1 um and lower

- Hard disk manufacturers: 0.2 um to 0.3 um

- Flat panel display manufacturing: 0.3 um and 1.0 um

A facility interested in spot checking cleanrooms for proactive assessments on a day-to-day basis requires a different instrument than a facility wide monitoring system for 24-hour data collection. Generally, handheld particle counters provide spot checking over smaller, localized areas. For large-scale dedicated monitoring, or cleanroom certification testing, bench top and dedicated remote systems provide ideal function.

Particles Plus

6-Channel Air Quality Monitor

Log data and generate environmental reports real-time on screen, via printer or USB key, or export to Particles Plus Instrument Management Software.

Related Posts

-

How to Choose the Right Cleanroom Particle Counter

Cleanroom particle counters differ widely based upon particle threshold, cost, and features. How to do you determine if you need a particle counter or what model of particle counter to purchase? In this article we…

-

New: Particles Plus Cleanroom Particle Counters and Air Quality Monitors

Cleanroom particle counters and anemometers offer portability, accuracy, and easy use. The self-contained devices allow local and off-site testing of air quality, air speed, HVAC efficacy.

-

How to Certify or Test a Cleanroom with a Handheld Particle Counter

How to Certify a Cleanroom with Kanomax Hand Held Particle Counters

-

How Often Does a Particle Counter Require Recalibration?

For ISO 14644 compliance, all particle counting equipment requires a calibration certificate.

-

Guide to Remote Particle Counters and Air Quality Monitoring Systems

Learn about the newest WIFI & IOT enabled air quality monitor features. Remotely monitor indoor & outdoor air quality including PM2.5 - PM10 particles, dust, C02, & VOCs.

1 thought on “What Is A Particle Counter? How Do Particle Counters Work? What Are They Used For?”

Comments are closed.