Table of Contents

AJ Lindell

Cleanroom Static Control & Applications Specialist at (PAC)

In What Areas Do You See Growing Demand in 2019?

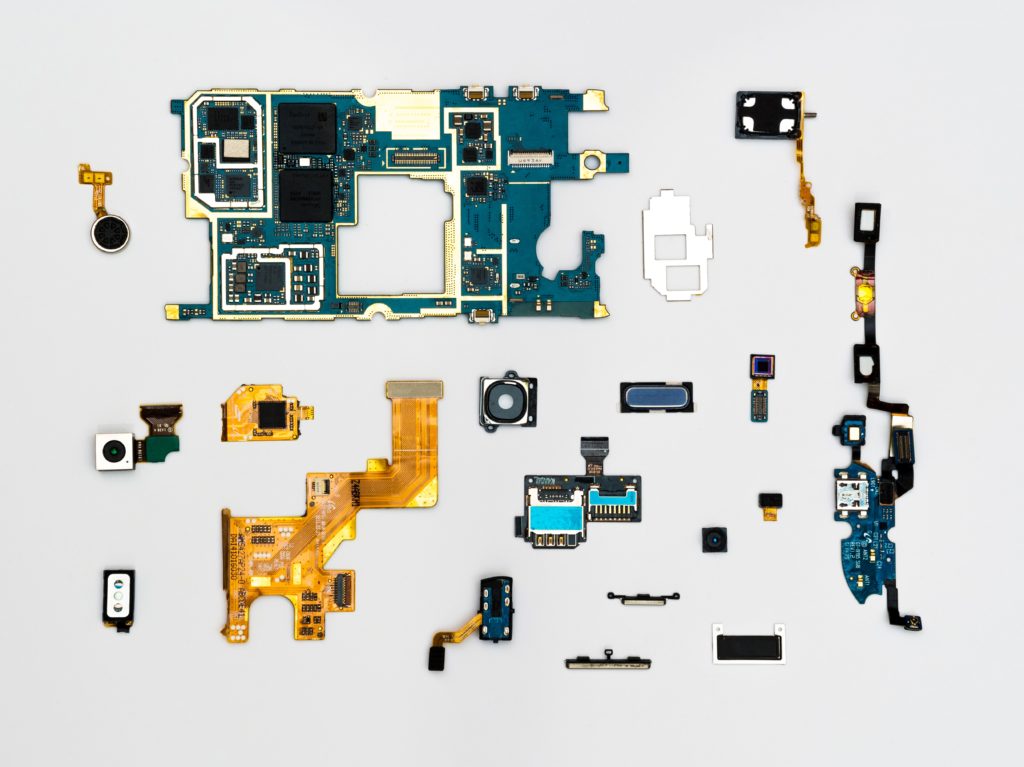

We continue to see an uptick in cleanroom needs, particularly from accounts whose businesses support OEMs via their subassemblies of electronics, medical devices, and components. These customers generally need to keep their facilities up to par with end-customer expectations, both aesthetically, and from a performance perspective.

What Products Do You Suggest When Particle Contamination and Debris Removal is Problematic?

Specialty gowning room equipment/fixtures, cleanroom static control, cleanroom workstations, as well as debris monitoring and particle control programs help them meet specialty needs.

Particle contamination and debris removal is a concern for many of our customers in controlled environments. Static control is growing in popularity for customers who recognize the benefits of ionization and dissipative materials for particle and debris reduction.

Through the use of critical static control monitoring systems, such as Simco Ion’s IQ Power Neutralizing System and ionizers, which can include Nova monitoring sensors, customers are able to chart a return on investment (ROI). As a result, they are seeing less costly rework, reduced scrap rates, and improved end-customer satisfaction.

Paula Ashley

Cleanroom Decontamination Specialist at (PAC)

What challenges do you see hindering the potential of the cleanroom market?

What is your company doing to overcome these challenges?

What do you think is needed to further develop the marketplace?

Customers require knowledge and credible information around contamination control so they can make informed decisions. We help customers establish best practices and vette compliance issues early, a crucial benchmark for not only enterprise cleanroom builds but particularly small-medium sized firms.

PAC can provide both expertise and product-driven solutions from a single point of contact where many firms cannot, e.g. employees having a high rate of burn incidents from handling large heat dissipating parts, or when a particular contamination profile is problematic or unidentified.

Cory Nordmeyer

Cleanroom Environment & Application Specialist at (PAC)

How Do Your Customers Tackle Increased Particulates when Production Hours Expand?

In some cases, companies extend operation by one or two shifts to reach production goals. The increased operator volume and shift changeouts can produce particulate issues and increase defect rates. Without dedicated air quality monitoring systems, understanding the source and severity of particle generation requires a 3rd party testing service. Handheld particle counters and air quality monitors are a growing trend helping manufacturers spot-check and identify contamination in real time without capital investments into hardwired monitoring systems. We often recommend hand-held solutions from Particles Plus, which enable remote monitoring, testing, recording, and reporting for up to 1000 unique cleanrooms or locations.

Read the Full Report

Big-ticket R&D projects in biopharma are the main driver of business for cleanroom solution providers in the US. The need for particle-free manufacturing spaces adds to the optimism in the market.

Related Posts

-

CleanPro® Softwall Cleanroom Enclosure

This customer needed to enclose a piece of machinery, and CleanPro® was able to provide a solution.

-

Construction Quality Eagle Cleanroom Table: Reviewed

Eagle Group carries some of our most popular and affordable stainless steel table options, from budget grade to specialty marine edge tables.

-

CleanPro® Turnkey Cleanroom Install

CleanPro’s turn-key cleanroom solution provided a one-stop, one-contact result for the initial delivery and on-site installation of walls, ceiling grids, electrical systems, flooring, filters, HVAC, and more.

-

CleanPro® Chemotherapy & CSP Cleanroom Installation

This modular, sterile compounding cleanroom is designed for USP 797 and USP 800 compliance, particularly for compounding chemotherapy drugs. Safe handling of sterile compounds requires special considerations: heat-welded floors, anterooms and buffer areas.

-

CleanPro Environmental Monitoring

CleanPro Critical Environment Monitoring Solution:Get real time reporting, alarm conditions, and instant traceability. CleanPro's Monitoring Solutions are sophisticated computer-based monitoring systems for critical applications. They are ISO-9001/2008 certified and the development processes meet cGMP standards.…

-

CleanPro® Softwall Cleanroom Curtains Installation

Softwall cleanroom curtains, sometimes referred simply as “plastic strips” yield ISO Class 10,000 level particle control with minimal construction. This customer required a custom softwall installation that integrated into their existing building structure CleanPro to…