Table of Contents

Overview of BOFA Technology Fume Extractors

Advanced manufacturing processes require extensive consideration for air quality management. BOFA flow hoods and fume extractors cater to tasks which produce aggressive microparticles and fumes. By curbing contaminants, facilities reduce inspection failures and late-stage defects caused by excessive particulate buildup. Stand-alone fume management systems feature plug-and-play support, performance monitoring systems, and dirty filter indicators quickly forecast manufacturing hazards such as blocked filters, filter load, and poor filtration efficacy.

BOFA Filtration Technology

BOFA combines pre-filtration systems and high-efficiency particle filters that remove 99.997% of particles 0.3 micron in size. This ensures that clean air is maintained in the workplace, while patented features such as DeepPleat DUO combines reverse flow air technology for optimized filter life and lower cost of ownership.

What is the BOFA iQ Performance System?

The BOFA iQ system is a patented central processing unit which connects a number of sensors to a real-time data output on an internal display. The system includes alarm and data logging, USB data control, a real-time clock, and I/O controls. The system adjusts motor drive and fan speeds for optimal filter efficiency when the unit experiences pressure loss due to blockage or overload.

Set Flow Rate with Automated Presets

This iQ system enables the user to set the required airflow rate, then over time as the filters begin to block the motor will automatically begin to increase in speed to compensate for any loss in performance caused by the added restriction of the partially blocked filters. The set airflow will now be maintained throughout the life of the filters. When the extraction unit can no longer maintain the set airflow, an alarm will sound and the display will indicate which filter requires replacement.

Best Fume Extractors for Laser Engraving & Cutting

AD Oracle SA iQ Fume Extractors

The BOFA Oracle fume extractor is one of the most advanced compact laser fume extractors on the market. Oracle enhancements include BOFA’s iQ Operating System, Advanced Flow Control (AFC) and Reverse Flow Air (RFA) technology. The iQ Operating System extends operation and clarity of real-time information with a cache of analytical data, enabling users to download performance and operating parameters for evaluation purposes. The iQ system enhances both performance and safety parameters for the least amount of downtime and long filter life.

AD iQ Fume Extractors Fume Extractors

The AD 1500 iQ high-end laser extraction system combines extremely large filter capacity with high airflow and pressure rates, making it the ideal choice for heavy-duty applications that generate large amounts of particulate and gaseous organic compounds. Performance has been further enhanced with the inclusion of several features including BOFA’s acclaimed patented iQ system, making the AD 1500 iQ one of the most advanced systems available.

Best Fume Extractors for Soldering

Fume extractors are found in nearly every manufacturing area hosting excessive chemical vapors, aerosols, and particulates. Soldering fume extractors generally use vacuum hoses for “on-spot” filtration when applying solder paste, flux, solvents and adhesives.

BOFA V 200 Soldering Fume Extractor

The BOFA V 200 fume extractors are ideal for hand soldering processes. Its adaptable arms allow unique configurations for reaching the point of extraction. The system is portable and comes complete with an installation kit and everything you need for a quick installation. The system operates quietly and contains a three-stage filter system including pre-filters which reduce recurring operating costs.

BOFA T1 & T15 Soldering

The BOFA T15 is a high volume fume extraction system with a built-in silencer for extremely low noise levels. With its three-stage filtration and filter warning indicator, this is a true industry favorite, suitable for 5 -15 operators/extraction points. The T15 extracts and filters fumes and debris through small bore hoses and attachments. Ideally, this system is suited for multiple workstations with soldering iron tip extraction, vac pens and any application requiring close proximity use.

Best BOFA Fume Extractor for Fluids, Chemicals & Coatings

Fluids, coatings, and chemical applications require various fillers, solvents, and adhesives for component assembly or rework. The processing, handling, and administration of these contents present numerous exposure risks including irritation, incapacitation, respiratory ailments, or even combustion and chemical burns. Fume cabinet workstations with multi-stage filtration systems feature inline HEPA and carbon-activated filters which capture both chemical vapors and particulate when combined with a BOFA fume extraction system.

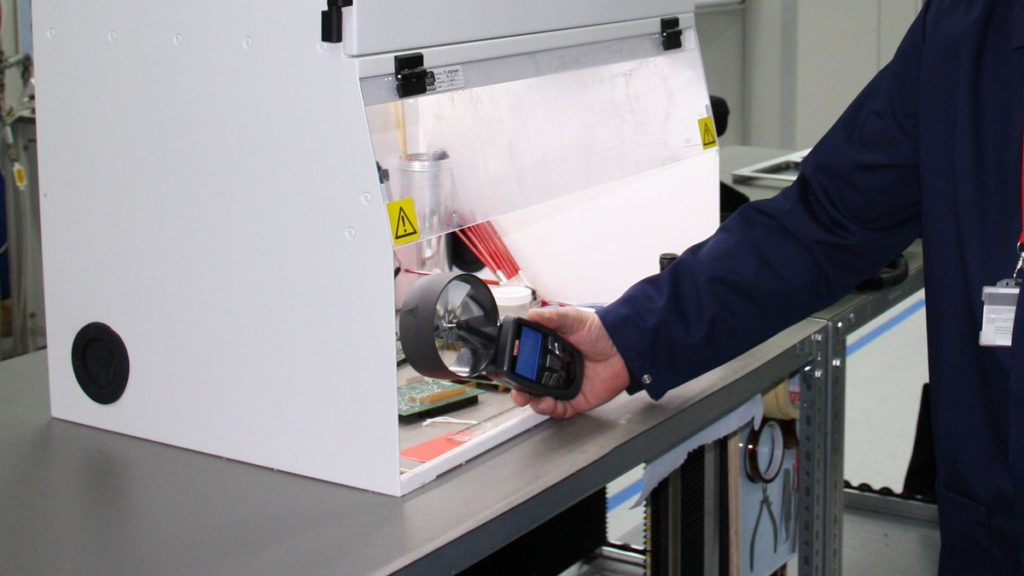

BOFA CAB 700 Fume Extractor Cabinet

BOFA partial enclosures are a fume extraction option for a variety of applications. The FumeCAB 700 features an integrated filtration system which exhausts fumes and vapors. The easy change filter design enables safe and simple front loading filter replacement. Ultra-bright slim-line energy saving LED lights come as standard with optional UV lighting. UV lighting is ideal for applications such as the conformal coating of PCBs for identification of uniformity issues.

Processing hazardous chemicals or drugs is multifaceted with a wide set of applications varying between automated robotic systems and simple hand dispensing methods. Most will benefit from speaking with an applications specialist to ensure proper pressure balance and surface velocity for safe use.

When you purchase a fume extractor from PAC, you’ll receive a number of value-added services including end-to-end product support from application experts. We evaluate your production environment, product sensitivity, and provide product solutions for any standard of air quality or exposure guidelines. We stand 100% behind all of our products, which means we’ll also facilitate replacements in the rare case that a product arrives damaged or defective.

Related Posts

-

BOFA Fume Extractors for 3D Printing

3D printers are known to produce a number of byproducts during operation. Common 3D printing filaments such as ABS and PLA are known as high emitters of ultra-fine particulates (UFPs), while nylon and PCTPE are…

-

3D Printing Fume Extractors for Odors and Particles

Does a HEPA filter capture ultrafine particles (UFPs). What toxins does 3D printing produce? Why should every 3D printer have both a activated carbon and HEPA filter?

-

BOFA Fume Extractors for 3D Printing

3D printers are known to produce a number of byproducts during operation. Common 3D printing filaments such as ABS and PLA are known as high emitters of ultra-fine particulates (UFPs), while nylon and PCTPE are…

-

The Difference Between Solder Fume Extractors & Smoke Absorbers

Here you'll learn about soldering fans, fume absorbers, and fume extractor applications. Some may require a fan for soldering while others need a more advanced solution for laser engraving, solvent use, or 3D printing. It's…

-

Why Do I Need Fume Extraction?

There are many applications where fume extraction is necessary and/or required by law. Manufacturing and assembly operations, repair centers, salons, ect. Anywhere where there are harmful fumes and particles in the air that can be…

1 thought on “BOFA Extractors for Soldering, Lasers, Cutting, Dust and Engraving”

Laser technology is so much more versatile than some might believe; what seems like an efficient method of design is also an effective marketing technique and prevents forgery, among other things. Great article