BOFA Fume Extractors Overview

BOFA is a worldwide manufacturer of fume and dust extractors for many industrial sectors and applications. As performance and safety is a priority, its product categories help you identify a system built specifically for the task at hand. It’s a popular choice for advanced manufacturing processes such as 3D printing, solid state lasers, optical fiber technologies, fluid dispensing, and high-speed packaging lines.

BOFA 3D Printing Fume Extractors

Reducing 3D Printing VOCs and Fumes

3D printers are known to produce a number of byproducts during operation. Common 3D printing filaments such as ABS and PLA are known as high emitters of ultra-fine particulates (UFPs), while nylon and PCTPE are known for high levels of volatile organic compounds (VOC) concentrations. Once airborne, particles and noxious fumes are easily absorbed into the lungs where they can enter tissues and cells.

Reducing Ultrafine Particle Levels

Particles smaller than 100nm are referred to as ultra-fine particles (UFPs). Because these particles are so small, standard air filters and even HEPA filtration may not be sufficient in capturing and retaining all particles. UFPs become airborne more easily because of their small size. While large particles generally settle quickly, UFPs are able to transverse large areas of space. Greater buoyancy allows airborne suspension for long periods of time, sometimes up to 48 hours.

BOFA Combination Filters & Replacements

HEPA Filter

The mini pleats used in the HEPA filter can be produced with depths of up to 200mm within each pleat, depending on the application. They are generally manufactured by specialist filter companies to ensure that the latest manufacturing and test methods are adopted. Each filter incorporates a series of webbing between the pleats. This feature not only guarantees even spacing for full filter coverage between each pleat, but also alleviates the possibility of airflow vibration or collapse. BOFA HEPA filters are tested to filter 99.997% @ 0.3 microns.

Chemical and Gas Filters

Contaminated air must remain in contact with the carbon bed for a period of time sufficient to ensure that no contaminants or odors are emitted. The product designs consider the balance between air flow rates and the type, depth and surface area of the carbon used to ensure suitability for the contaminants associated with the application and to ensure that appropriate dwell times are achieved. The filters have been developed to capture all contaminants and odors, eliminating the risk of bypass and/or tunneling.

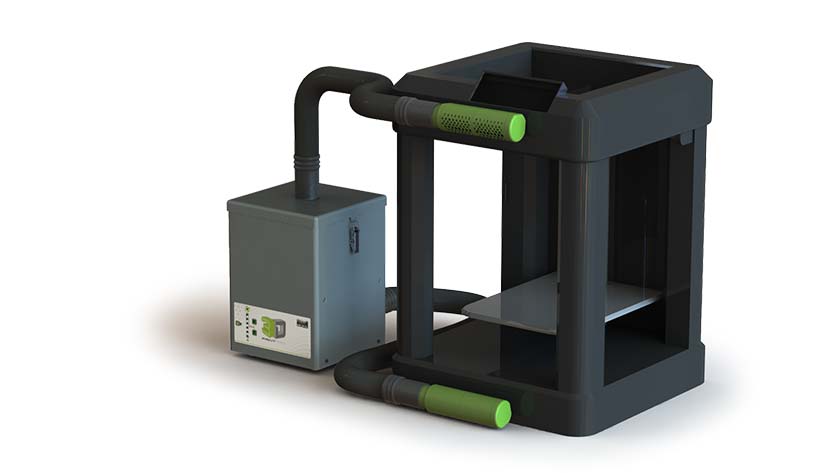

3D PrintPRO 2 Fume Extractor

The 3D PrintPRO 2 is economical systems used alongside a open-face 3D printers. Nozzle or funnel options capture fumes and particulates and provide both chemical and particulate removal via carbon and HEPA filter. The extraction point needs to be as close as possible to the printing area without interfering with the 3D printing process to ensure filtration efficacy. An optional remote start/stop feature allows the operator to engage and turn off the system via a remote signal.

The 3D Print Pro 2 contains a combined filter with options for extended hose kits. These should be replaced when instructed to do so by the 3D Print Pro extraction system. When the filter becomes full the red “Filter Condition” light will glow. The combined filter is manufactured from non-toxic materials. Filters are not reusable, cleaning used filters is not recommended. The method of disposal of the used filters depends on the material deposited on them. Filter media in contact with hazardous waste must be disposed of as such in accordance with local and federal regulations.

Print Your Air Plenums with the 3D PrintPro

BOFA offers ‘print your own’ inlet and outlet plenums to be used as an accessory to your 3D PrintPRO 4. When installed the inlet and outlet plenums extract fume and flood the operators breathing zone with clean filtered air, creating a recirculating extraction system. The plenums are split into four pieces and can be adjusted in length to suit the printer by simply adding or removing middle sections. The files needed to print the plenums can be found on the BOFA website or are available by request.

Extraction Only (3D PrintPRO 2)

The inlet plenum is an ideal addition to the 3D PrintPRO 2 extraction unit. The plenum will capture fume generated during the 3D printing process. The extraction unit will filter the air before exhausting it through perforations at the base of the unit. Unlike the 3D PrintPRO 3, the PrintPRO 2 is not capable of operating a recirculating extraction system. An outlet plenum cannot be fitted to the 3D PrintPRO 2.

Recirculating System (3D PrintPRO 3+)

The 3D PrintPRO 3 and 3D PrintPRO 4 can be fitted with both an inlet and outlet plenum making it capable of operating a recirculating extraction system. This unit can be fitted with both manifolds. The fume is extracted from the working area using the inlet manifold. The fume is filtered as it passes through the BOFA extraction unit before being put back into the operating area.

Related Posts

-

3D Printing Fume Extractors for Odors and Particles

Does a HEPA filter capture ultrafine particles (UFPs). What toxins does 3D printing produce? Why should every 3D printer have both a activated carbon and HEPA filter?

-

Filament Storage Cabinets for 3D Printing

Notably, filaments such as nylon may absorb unacceptable amounts of water in the short period of time they are on the printer. This cabinet provides active feedports for use during prints, and long term storage…

-

Filament Storage, Dry Boxes and Spool Cabinets for 3D Printing

Are you ruining your 3D printing filaments by baking them? What's the best way to dry FDM and PLA filaments? What about Nylon and PLA?

-

Why Do I Need Fume Extraction?

There are many applications where fume extraction is necessary and/or required by law. Manufacturing and assembly operations, repair centers, salons, ect. Anywhere where there are harmful fumes and particles in the air that can be…

-

Hakko FA-430 Fume Extraction System

The Hakko FA-430 Fume Extraction unit is expressly for use at soldering stations, extracting the contaminated air directly at the source. Contaminated air is captured from the workplace surrounding the soldering station by the hood…

-

Sterile 3D Printing Materials for Medical Devices

Is sterile 3D printing possible? Are 3D printed parts sterile? This comprehensive guide to 3D printing sterile parts provides materials that withstand various sterilization techniques such as autoclaving, heat, ETO, and gamma. Here's how 3D…