Air Filters and Efficiency

Grow Room Design for Commercial Medical Cannabis

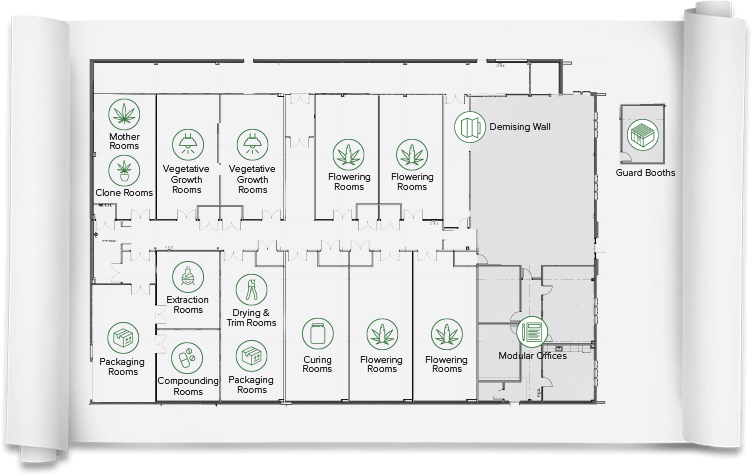

Modular grow containment systems shorten construction times while offering more customization and less build complexity. Cannabis grow rooms with modular components ease adaptation of adjacent structures for independent climate controls and parallel production. Environmental control and electrical designs are critical, but so are structural, architectural, and workflow considerations.

In the above graphic, the potential ratio and floor sizes of the flower rooms are under-represented. Flowering rooms may exceed thousands of sq. ft. Modular cleanroom design allows for unlimited expansion and partitions for various stages of processing, strains, and plant cycles. Mother, clone, and flower rooms flourish when temperature and humidity are maintained independently.

Grow Room Walls and Ceiling Heights

Unique containment rooms for clones, flowers, and seedlings provide environmental controls at each stage of the maturity cycle. Each room is built with prefabricated containment walls self-support the ceilings, electrical, and calibrated for the HVAC system.

A modular installation is faster, requires minimal tools, and requires no sawing or cutting. Scheduled delivery of pre-assembled components allows project management around operation-as-usual. Space and construction staging is minimal.

Cleanroom wall panels demonstrate unhindered control over exterior room dimensions and environmental conditioning. Modular wall panels extend design freedom. Insulation panels with variable R-value help balance cost and prevent over insulation. The ability to integrate electrical conduits, product pass-throughs, windows, ducting, air filters, and storage cabinets closes performance gaps. Operation space is designed as needed and ergonomics are optimized on an application-specific basis.

Prefab Grow Room Installation - Modular Prefab Panels

Independent construction of modular cleanroom components allows the removal of grow room walls or individual panels without disturbing adjacent panels, flooring, or ceiling systems. Quick disassembly and the ability to relocate grow rooms reduces labor burdens and favors ever-changing production layouts. Downtime and disruption of adjacent workspaces or grow rooms are minimal. Parallel, non-destructive builds reduce overall build time and mitigate intrusive noise, particulate, or foot traffic of traditional construction activities. The flexibility of modular designs allows the retrofitting of new structures around previously existing HVAC, electrical, and production systems.

Tax Advantages of Modular Cannabis Grow Rooms

Conventional building construction uses a depreciation schedule of 39 years, while modular construction is depreciated over 7 years. Temporary structures decrease tax burdens and offer a faster return on investment. The entire structure is a depreciable asset. The write-off-speed is an enormous benefit, given the current tax implications and rapid growth of the cannabis industry.

California Requirements for Multi-Stage Cannabis Grows

The Bureau of Cannabis prioritizes a hefty increase in regulations for cannabis cultivation. Partitioned dividing walls allow clear and clean separation between seedling, growing or processing spaces.

These are some 8106 notations that will shape designated cultivation space: (A) Canopy area(s) (which contain mature plants, at any point in time) including aggregate footage (B) Area(s) outside of the canopy where only immature plants shall be maintained, if applicable (C) Designated pesticide and other agricultural chemical storage area(s) (D) Designated processing area(s) if the licensee will process on site (E) Designated packaging area(s) if the licensee will package products on site (F) Designated composting area(s) if the licensee will compost cannabis waste on site (G) Designated secured area(s) for cannabis waste if different than subsection (F) above (H) Designated area(s) for harvested cannabis storageRelated Post: 8106 Cultivation Plan Requirements

Air Flow and HVAC Systems for Grow Rooms and Corridors

Microenvironments within larger umbrella structures such as large warehouses often lack proper insulation and air conditioning systems. Cleanrooms need air, and a lot of it to regulate temperature, air purity, and humidity. In most facilities, air systems consume over 60% of all the site power. As a general rule of thumb, the cleaner the grow room needs to be, the more air it will use. To reduce the expense of modifying the ambient temperature or humidity, AHU (air handling units) are designed to recirculate about 80% air through the room, removing particulate contamination as is it generated and whilst keeping the temperature and humidity stable. A well-designed air handling system delivers both “fresh” and “recirculated” filtered clean air into the cleanroom so that it flushes the particles more efficiently.

Particulate in the air tends to either float around or stick to near surfaces. Most airborne particles will slowly settle, with the settling rate dependent on the size of the particle.

"Pre-engineered construction and fixed installation time were the two biggest factors. Construction was completed in two weeks. The crew worked non-stop, nobody was ever sitting around waiting on materials, and we didn’t have to call for structural inspections to slow things down. Plus, the entire structure is a depreciable asset so you can write off the cost of your building in half the time you would otherwise, which is an enormous benefit given the current tax implications of working in the cannabis industry. Cleanroom design was the other big factor. The rooms have very high insulation value which improves cooling efficiency, and they are tightly sealed which improves humidity control and prevents cross contamination. This also allows us to deal with pollen without fear of seeding out one of our flower rooms. " - Mother & Clone

Mother & Clone

Air Flow and Pressure Design for Medical Cannabis Grows

Positive pressure grow rooms elevate room pressure so that outside air is not reintroduced if walls and panels have gaps, seams, and leaks in ceiling fixtures or conduits. Higher air pressure in a centralized room ensures that dirty air from surrounding rooms does not permeate into cleaner spaces, thus helping cannabis growers prevent cross-contamination via air currents or human-borne traffic.

"Typically, low moisture medicinal products such as tablets or capsules are dry and dusty, therefore more likely to be a significant cross-contamination risk. If the “clean” area pressure differential was positive to the corridor, the powder would escape out of the room and enter the corridor and is likely then to be transferred into the next door cleanroom. Thankfully, most dry formulations do not readily support microbial growth, so as a general rule, tablets and powders are made in “clean corridor” facilities, as opportunistic microorganisms floating in the corridor don’t find environments in which to thrive."

Mother & Clone

Power Distribution

Power distribution modules provide circuit protection and large-scale device amplification including support for lights and fan filters. These systems simplify cleanroom installation but do not provide a simple mechanism for automating or adjusting power levels dynamically. Remote air balancing systems route fan filter controls to a central control for macro and micro-adjustments.

Throughout the life of a filter, particulate slowly clogs air passage and air velocity decreases. Small speed adjustments ensure that the growing operation maintains an ideal air exchange and pressure cascade throughout each grow room or processing area. Independent velocity control also extends the life of the filters by eliminating unnecessary airflow loads while also decreasing energy costs.

Read: Modular Fan Filter Control System Construction and Components

Air showers prepare cannabis cultivators for grow room entry by pressurizing air to remove any contaminants, mites, or mold spores that cling to garments. They are three primary designs for air showers: a step in step out design, a straight-through design, and air showers for parts and equipment that enters a clean space. The advantage of a straight-through design is that it helps maintain pressure cascades and eliminates flow-through of any invasive particulate.

Air Showers

Get a Grow Containment Room & HVAC Quote

Our CleanPro® cleanroom division offers modular grow room walls and HVAC systems with custom integrated electrical and plumbing. We provide engineering, construction, and outfitting services all the way up to final delivery and installation. Our insulated systems fit together with an air tight seal and world-class HVAC modules. No hardware, no sawing or cutting.

Related Posts

-

Sealed & Portable Medicinal Cannabis Grow Rooms

Modular cannabis grow room designs improve the longevity of grow room construction. Likewise, portable prefab grow rooms allow for more adaptable configurations when expanding, relocating, or re-purposing a grow room. There are also a number…

-

Gowning Room Design – Guidelines, Anterooms, and ISO Classification

A gowning room has many variables. There is no mathematical formula when determining the features, surfaces, and HVAC requirements best suited for your application. Space requirements, volume of operators, aseptic workflows, material choice, and even…

-

Advantages of Modular Grow Room Design

Modular grow room systems improve design freedom when dividing a floor plan into separate areas for flower, clone, or veg rooms. Prefabricated structural walls, T-grid ceilings, insulated panelized roofs, and specialized cleanroom-grade panels reduce installation…

-

Why Every Cannabis Grow Room Design Should Incorporate an Air Shower

Most cannabis facilities prefer over-sized air showers, as transport carts and pallet jacks are often required at the beginning and end of grow cycles. Extra large air locks and pass-through air showers allow the passage…

-

Why Build a Grow Room with CleanPro?

CleanPro® (that’s us) helps you build grow rooms with world-class climate control. Just tell us what you need, and we'll bring it to life. Our engineering team conducts preliminary research, provides blueprints, and coordinates your…

-

4 Ways to Maintain a Clean Grow Room

Grows rooms often provide a safe harbor for invasive insects, molds, fungus, and microbial pathogens. While one option is building a hyper-clean cannabis cultivation room, below we provide more economical production solutions which dramatically reduce…