Table of Contents

Surface Wipedown and Decontamination for Infection Diseases and Viruses

Crucial areas like hospitals, factories, pharmacies and high-volume areas require thorough and complete cleaning methods; proper protocols improve cleaning efficacy but also prevent or stop cross-contamination and re-contamination.

Correct use of decontamination consumables and appropriate guidelines are a reliable way to safeguard these areas.

How to Wipe and Sanitize a Contaminated Surface

1. Always follow relevant site protocols and procedures; this should include wearing appropriate gloves and garments.

2. Fold the wiper into quarter folds. This will provide several clean surface areas and allow better contact with the surface to be wiped.

3. When wiping, hold the wiper so that the folded edge is toward your fingertips. Hold the unfolded edges in your hand. Group the unfolded edges between your thumb and forefinger.

4. Use either a pre-wetted wiper or a dry wiper moistened with an appropriate cleaning agent.

5. Wipe in one direction, overlapping wiped area by 10% to 25%.

6. Wipe from cleanest to least clean regions of the surface being wiped. Wipe systematically, so from top to bottom, or far to near, in a linear vs. circular motion.

7. Be sure to keep track of which surfaces have been cleaned and which wiper areas are unused.

8. Always use the cleanest surfaces of the wiper. If re-wiping, use a clean portion of the wiper, not the used wiper area.

9. Dispose of wipers according to established site procedures.

- Source: Teknipure Surface Wiping Guide

What’s the Advantage of Microfiber Wipes for Surface Cleaning?

Microfiber wipers improve “pick-up & hold” capabilities compared to traditional cloth, paper, or polyesters. Polyester & nylon blends result in very small filament size and increased density over the surface area.

Microfiber is beneficial in critical cleaning when removing surface contamination. However, there is an increased cost compared to traditional polyester knit fabrics. Economics do play a role in product selection.

A microfiber product when combined with an appropriate sanitizer would be the best choice as the microfiber will remove up to 99.9999999% of surface contamination. Depending on the application a use, a microfiber flat mop (non-woven, knit, woven) and microfiber wiper (non-woven, knit, woven) are common recommendations.

Data on Microfiber Wiping Materials and Mops

Some hospitals have begun using a new mopping technique involving microfiber materials to clean floors. Microfibers are densely constructed, polyester and polyamide (nylon) fibers, that are approximately 1/16 the thickness of a human hair. The positively charged microfibers attract dust (which has a negative charge) and are more absorbent than a conventional, cotton-loop mop. Microfiber materials also can be wet with disinfectants, such as quaternary ammonium compounds. In one study, the microfiber system tested demonstrated superior microbial removal compared with conventional string mops when used with a detergent cleaner (94% vs 68%). The use of a disinfectant did not improve the microbial elimination demonstrated by the microfiber system (95% vs 94%). However, use of disinfectant significantly improved microbial removal when a conventional string mop was used (95% vs 68%)(WA Rutala, unpublished data, August 2006). The microfiber system also prevents the possibility of transferring microbes from room to room because a new microfiber pad is used in each room.

CDC – Guideline for Disinfection and Sterilization in Healthcare Facilities, 2008

(PAC) often helps customers save money by suggesting a high-performance wipe in critical areas and more economical wipes for general cleaning.

Teknipure knit and woven microfiber wipes are effective for general surfaces, as well as ISO 3-5 environments.

How to Prevent Cross Contamination

Discard each wiper after initial use and prevent cross-contamination or re-contamination. Mops or wipes should not be laundered and reused, otherwise there is a chance to re-contaminate the area. Following proper cleaning procedures are crucial to ensure best-case decontamination.

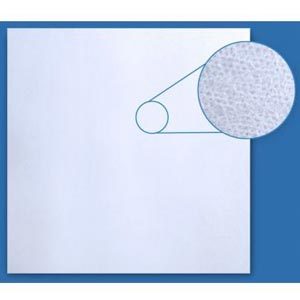

Teknizorb Polyester/Nylon Nonwoven Microfiber Wipers

Hydro-entangled microfiber (also known as Spunlace) substrates are made by entangling fibers with hi-pressure jets of filtered water which provides a clean and strong material bond. TekniZorb non-woven wipers are manufactured using a blend of polyester and nylon microfiber.

What’s the Advantage of Presaturated Wipes?

Wipes perform best when lightly saturated with an appropriate cleaning fluid (typically solvent blend) which “attracts” contaminants and eliminates static.

Saturating wipers by end-users, on site with gloves, may lead to inconsistent results and over-saturation deposits, as opposed to attracting contamination.

TekniSat wipers provide superior contamination removal, and precise solvent saturation to ensure optimal attraction, retention, and reduce solvent requirements. Available in multiple materials, packaging options, and solvent solutions to meet various environmental and process-cleaning applications.

Wipes saturated with a sanitizer like 70% IPA (Isopropyl Alcohol), or a disinfectant kill most common viruses and bacteria on non-porous surfaces. Non-woven saturated wipes will cover ISO 6-8 cleanroom environments. Woven knit products support all ISO classes 3-8.

TekniSat wipers provide contamination removal and precise solvent saturation to ensure optimal attraction and retention while also reducing solvent usage. Wipes saturated with a sanitizer like 70% IPA (Isopropyl Alcohol) kill most common viruses and bacteria on non-porous surfaces.

All Teknisat wipes use Statistical Process Control in manufacturing and are lot traceable from raw material to finished product. Wipes are presaturated with 0.2micron filtered IPA which is 99.999% pure and blended with 18 Mohm De Ionized water. Class 10 Laundered & Packaged.

Why We Support Teknipure Wipe Products

PAC offers cleanroom cleaning solutions from dozens of manufacturers. Teknipure is one example of a manufacturer-direct product available on our web store and our cleanroom specialty store, cleanroomproducts.com

Teknipure maintains internal controls and safeguards to keep staff healthy and production continuous. Its team operates in low-contagion environment — an ISO 5 cleanroom with HEPA filtered air, full garbing, and face masks.

Teknipure Quality Advantages

- Recently expanded in-house manufacturing operations

- High standards support all of our cleanroom customer needs

- Innovative controlled environments consumable contamination solutions

- Awarded the coveted ISO 9001:2015 certification development

- Strong quality program for our customers

For inquiries about Teknipure Solutions, send us an email, give us a call, or answer a few questions and we’ll have a specialist get in touch with you.

Contamination control guidance and purchase support are available for specialty applications and environments.

Teknipure is known for its high performance wipe materials in dozens of industries. At PAC you’ll find dozens of Teknipure wipe products including options for saturated, dry, and specialty wipers.

PAC continually expands important product lines to provide new diverse options and best performing products for both high-performance sectors and general cleaning.

There are many options for surface and floor cleaning. New mopping configurations and materials improve speed, performance, and ease.

Note: Follow The Guidance of Health Officials

Health officials have shared that the best policy is minimal interaction with others (when possible) and wear face masks when social distancing is not possible. Enhance surface hygiene, keep hands away from the face, and wipe surfaces with cleaners that kill the virus to prevent exposure.

Disclaimer

Sanitizers and sterilants for hard and non-porous surfaces are not to be confused with medical treatments and/or medical remedies.

PAC (that’s us) is a commercial contamination control and purveyor of supplies needed for the manufacturing of medical devices, healthcare supplies, and pharmaceuticals, and general manufacturing.

We will not respond to requests for medical consultation or patient-specific advice. If you need healthcare advice, please contact a healthcare professional or licensed physician.

Web content provided by Production Automation Corporation (PAC) makes no claims as to the final interpretations or implementation of regulatory documents, organizational standards, or best practices as provided by stakeholders, local authorities, CDC, FDA, OSHA, NIOSH, EPA, Poison Control, State Board of Pharmacy, or United States Pharmacopoeia (USP).

Related Posts

-

New: Texwipe Cleanroom Products

Texwipe offers a variety of dry, pre-saturated, and sterile wipes to meet the strict demands of controlled environments. Texwipe swabs are manufactured to exacting and consistent tolerances with lot coded for traceability and quality control.

-

Cleanroom Mop Procedure - How to Mop a Cleanroom with a Multi-Bucket System

Learn how to properly mop a cleanroom for ISO class or cGMP cleanliness levels. Compare designs and materials of multi-bucket cleanroom mop systems.

-

New: Vileda Professional Cleanroom Products

Vileda Professional Cleanroom Mops support most critical applications. Find stainless steel mop sets and handles, or ask about quantity discounts on Vileda mop refills, pads, and accessories.

-

Cleanroom Sticky Mat Frames Now at PAC

The perfect frame for any cleanroom sticky mat. Carpet, concrete, grimy, oily, damp or temporary walkways often yield unreliable or inconsistent adhesion for floor mounted tack mats. Cleanroom sticky mat frames provide a movable base…

-

New: Texwipe Cleanroom Products

Texwipe offers a variety of dry, pre-saturated, and sterile wipes to meet the strict demands of controlled environments. Texwipe swabs are manufactured to exacting and consistent tolerances with lot coded for traceability and quality control.

-

New: Perfex Cleanroom Mop & Disinfection Systems

Perfex cleanroom mop and disinfection systems are designed for easy use and maintenance for critical operations. It's the cleaning performance you'd expect beyond old-style buckets, wringers, string and sponge mops.

-

How Do I Properly Wipe Down Surfaces in Cleanrooms and Labs?

What are the proper steps for wiping surfaces, biological isolators, and laminar flow cabinets, and excess hazardous drugs?