Medical cannabis cultivators understand that control over environmental, genetic, and nutrient variables are an undisputed production advantage for photosynthetic plants. Less understood are the ways in which clean garments and flooring systems prevent inbound contamination.

Clean environments reduce residual spore counts, bacterial colonies, and sometimes mites, which ultimately reduces the need for pesticides and curbs cleaning burdens between harvest cycles. History has shown that ill-advised manufacturing controls lead to unknown risk, late-stage market failure, and crippling penalties. While not every cultivator requires a custom modular grow room, simple barriers can make a difference in saving a crop from opportunistic powdery mildew and fungus.

By The Time You See It, It's Often Too Late

Plants, soil, and people account for the majority of cannabis contamination sources. However, transport carts, dollies, and tools must also be acknowledged as carriers. At 60 microns, a dust speck in a sliver of sunlight is visible unlike spores, allergens, and pathogens within a range of 1-10 micron. Below are a few ways facilities reduce invisible, high risk contamination like spores and pathogens while also reducing cleaning costs associated with janitorial upkeep.

Shoe Covers for Cannabis Grow Rooms

Shoe covers, also known as shoe booties are an essential item for every clean-forward environment. We provide shoe covers in a number of styles and material compositions tailored to unique applications. For cannabis growers, we recommend a waterproof coating that prevents seepage and water transfer.

AquaTrak® material provides superior slip and fall protection in both wet and dry conditions. This advanced material was specifically developed to outperform the market in wet conditions. AquaTrak® is a fluid resistant material and performs well even in low-level standing water.

Peel and Tear Sticky Mats

Sticky mats contain 30-layers of particle trapping plastic, which peel off by hand once saturated. These mats are common across dozens of industrial applications including construction, sporting events, real estate, and other dirty and dusty processes in sensitive areas. Peel and tear sticky mats are generally not ideal for cart and wheel traffic unless installed with a dedicated frame to prevent the mat from pulling up.

Tack-Regenerating Mats for Spores

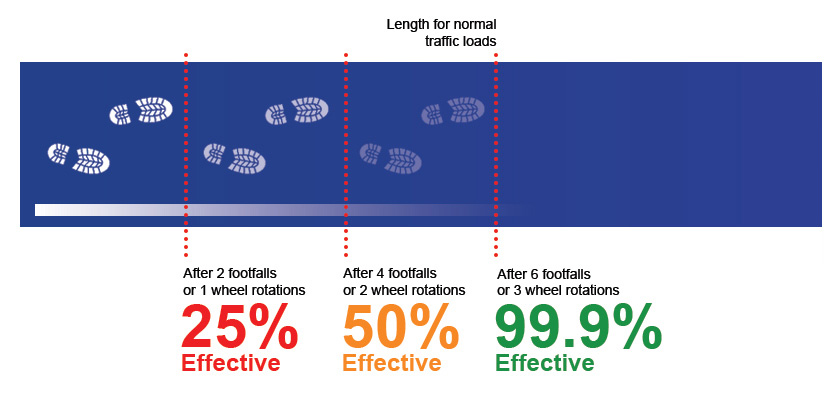

In clean grows, floor-mounted contamination control mats, also known as “sticky mats”, capture spores, organic matter, and grit from feet and carts at critical entryways for later cleaning. The mat captures 99% of particles as small as 0.5 microns in just three steps or three full rotations of a wheel. Polymeric tack-regenerating materials allow easier cleaning and prevent further contamination sprawl. Unlike traditional “peel-off” designs which require hand removal of plastic strips, a quick mop and squeegee restores tackiness without plastic waste.

Permanent tacky mats avoid the disposal of dirty plastic strips used by peel and tear systems. Instead of a disposable mat, regenerating systems feature a polymeric surface which captures and retains particles for later cleaning. Permanent tacky mat systems are most common in controlled environments, as they do not require any peeling or tearing by hand. For grow rooms these provide a green friendly option that actively prevents the introduction of spores, organic matter, and grit. Overall, a regenerating tack system reduces cleaning and contamination burdens not just in select areas, but across the facility.

Anti-Fatigue Mats for Packaging Rooms

Anti-fatigue with antimicrobial materials provide another way for growers to improve the comfort and efficiency in processes areas. Anti-microbial mats clean easier and will not promote microbial growth which supports use in wet and damp growing environments. A smooth surface and plush cushioning reduce spinal compression by distributing body weight more evenly. A facility-wide system uses modular mat designs which cover large expanses of production walkways. Each mat is available with unique textures that support extra grip or personal preference.

Gowns and Masks

Some of the most common cleanroom contamination include solid dust, liquid, bacteria, fungus, human skin cells and hair, trace moisture, spills and leaks, cosmetics, perfumes, lint, fibers, and more. The vast majority of cleanroom contamination comes from those that work within it. The most simple garments provide a crucial barrier between what employees brought to work from their homes, the outdoors, and high-volume entryways.

Find Clean Grow Room Supplies

We help licensed cannabis facilities produce clean yields faster with biomedical-grade contamination controls, apparel, and manufacturing products. Keep your grow room stocked & supplied with clean garments, protective apparel, gloves, shoe covers, mats, and more.

Related Posts

-

Hog Heaven III Anti-Fatigue Mats | Modular Mats

Select interconnecting Hog Heaven tiles and end pieces for outstanding anti-fatigue qualities in dry areas. The wedge locking system allows for unlimited configuration on walkways or assembly lines for increased grip, electrical conductivity, and weld-safe…

-

Electric Heated Mats for Snow and Ice: Andersen Company

Connect up to 4 mats in in sequence for up to 20’ (6m) of heated coverage for doorways, walkways, entrances, and more.

-

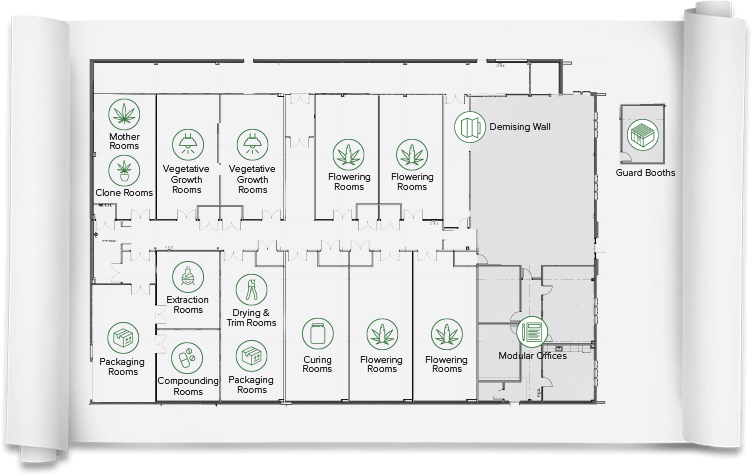

Advantages of Modular Grow Room Design

Modular grow room systems improve design freedom when dividing a floor plan into separate areas for flower, clone, or veg rooms. Prefabricated structural walls, T-grid ceilings, insulated panelized roofs, and specialized cleanroom-grade panels reduce installation…

-

Sealed & Portable Medicinal Cannabis Grow Rooms

Modular cannabis grow room designs improve the longevity of grow room construction. Likewise, portable prefab grow rooms allow for more adaptable configurations when expanding, relocating, or re-purposing a grow room. There are also a number…

-

New: Rhino Anti-Fatigue Mats

Search Rhino antifigue mats for dry and wet areas. Mats have chemical, abrasion and grease resitance features. Get free shipping on orders over $100. Find the most popular anti-fatigue mats for standing, kitchens, assembly lines,…

-

Helpful Tips for Choosing Entryway Mats

Entryway mats are key to keeping your floors clean and safe. Here are several things to keep in mind when buying an entryway mat. The first thing to consider, where will the mat be located? There are…