This article is also available in Spanish.

Negative Pressure Rooms: A Key Component of Infection Control in Healthcare

Negative pressure rooms have received increased attention in news headlines, following a Washington State case where a woman with untreated tuberculosis was involuntarily isolated in a negative pressure room. Washington officials are holding the woman in isolation with hopes of getting her the necessary, life-saving treatment needed to protect her own health and the health of the public. But what is a negative pressure room? What role do these rooms play in healthcare?

What is a Negative Pressure Room?

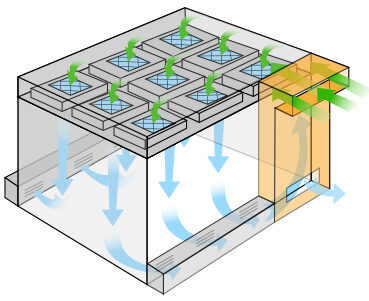

A negative pressure room is an isolation space that uses lower air pressure to keep potentially harmful particles from escaping the area. This isolation helps prevent the spread of airborne infections to other areas of a hospital or medical facility. These rooms are built using a ventilation system that pumps air out of the room at a slightly higher rate than the air intake. This creates a negative pressure differential, meaning that the air pressure inside the room is lower than the air pressure outside the room.

Negative pressure rooms experience outward airflow when their doors open due to air pressure differences. This helps prevent contaminated air from escaping into the hallway or other facility areas.

A high-efficiency particulate air (HEPA) filter usually processes the air removed from a negative pressure room before it’s released outside. This helps remove any harmful particles from the air before they can spread to other areas.

Negative Pressure Rooms in Healthcare

Negative pressure rooms are an important tool for infection control in hospitals and medical facilities. They help to protect patients, visitors, and healthcare workers from exposure to potentially harmful diseases. These rooms are commonly used to isolate patients with contagious, airborne diseases such as measles, tuberculosis, SARS, MERS, and COVID-19. By maintaining a lower air pressure inside the room than outside, negative pressure rooms prevent contaminated air from escaping and spreading to other areas of the hospital.

In addition to their role in infection control, negative pressure rooms can also protect vulnerable patients from exposure to harmful substances. For example, patients undergoing chemotherapy or radiation therapy are often isolated in negative pressure rooms.

The use of negative pressure rooms has become increasingly important in recent years, as the number of patients with contagious diseases has increased. In the wake of the COVID-19 pandemic, negative pressure rooms became even more essential for protecting patients and healthcare workers.

In the case of the Washington State woman, negative pressure rooms are serving as a control and isolation mechanism to keep the public safe and stop the potential spread of TB. With the appropriate treatment and isolation period, there is a greater potential for a full recovery and safe reintroduction back into society.

Learn more: Negative Pressure Rooms for Hospitals and Emergency Rooms

Negative Pressure Room Design

The design of a negative pressure room is critical to its effectiveness in preventing the spread of airborne diseases. The room must be tightly sealed to avoid air from escaping, and the air ventilation system must be able to create and maintain a negative pressure differential of at least 0.01 inches from the water column.

Important Components of a Negative Pressure Room

Air ventilation system

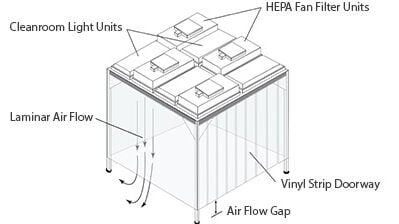

Air ventilation systems are responsible for creating and maintaining the negative pressure differential in the room. These systems typically consist of an air supply unit, an air exhaust unit, and a HEPA filter. The air supply unit brings in fresh air from outside the room, and the air exhaust unit removes the air from the room. HEPA filters remove harmful particles from the air before it is exhausted from the room.

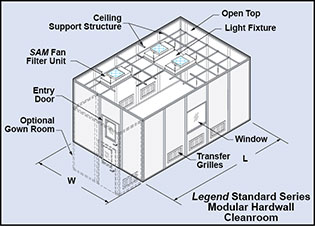

Doors, Windows & Walls

A negative pressure room’s doors and walls will differ depending on the type of walls used for its design. With hardwall designs, any doors and windows will be sealed shut. The doors are also self-closing to help maintain the negative pressure differential. In softwall designs, a softwall material for negative pressure applications will be selected and installed in a way that creates a tight seal. These softwalls used in tandem with the negative airflow system will keep the contaminated air from the room.

Flooring

The flooring of a negative pressure room is made of a non-porous material for easy cleaning and disinfecting.

Important Considerations When Designing

- Size: The room is large enough to accommodate the patient and any necessary equipment.

- Location: It’s best to have the room in a central location in the hospital for easy access.

- Signage: There needs to be clear signage indicating the area as a negative pressure room.

- The training of healthcare workers: Healthcare workers who work in negative pressure rooms require training to use the room properly and prevent the spread of infection.

Negative Pressure Room Design and Installation from PAC

Design

PAC works directly with customers and manufacturers for end-to-end engineering of containment structures, filtration systems, and installation hardware. We handle all the upfront engineering for manufacturing, including the final form, fit, and function of the on-site system.

Installation

For smaller containment systems, most facilities will handle the installation internally via the facilities team or a familiar contractor. These systems are extremely simple to erect and wire with basic tools and hardware, thus virtually zero modification is required for on-site installation.

Our existing cleanroom walls can be repurposed to build isolated patient partitions in medical triage tents, intake, screening, or temporary care areas.

Customized Dimensions & Features

- Dimensions are customized to your space.

- Easily integrate windows and openings appropriate for your business.

- Hygienic & Functional Design.

- Prevent physical contact while maintaining normal interactions, such as barcode scanning.

- Tri-panel design mitigates airborne transmission from coughing or sneezing.

- Easy to Clean.

- Hygienic aluminum and acrylic material can be cleaned using wipes, bleach, or disinfectant.

Negative Pressure Rooms for Hospitals

Production Automation Corporation (PAC) is a factory-direct cleanroom supplier for environments, supplies, apparel, and furniture.

Every PAC product is backed by dedicated customer service, sales support, and in-house specialists.

Need help with a technical manufacturing solution? We’re the specialists in your back pocket.

Related Posts

-

Negative Pressure Rooms for Hospitals and Emergency Rooms

What are the options for temporary negative pressure triage and emergency room structures?

-

Droplets vs Airborne - Science of Airborne Droplets, Aerosols, Particles, and Face Masks

Aerosols vs Droplets - does COVID-19 spread by aerosols or droplets? Does evidence support airborne coronavirus? 15+ studies on COVID particle size, droplets, ventilation, and face masks.

-

USP 800 Cleanroom Design - Negative Pressure Changes and Requirements

What equipment and engineering controls do USP 800 cleanrooms require? What types of storage and monitoring systems will I need?

-

Cannabis Drying Trays - Prevent Mold & Bacteria in Drying Rooms

A patent-pending clamshell rotation design improves storage harvest efficiency by allowing a complete rotation for top and bottom-side drying.

-

Garments, Shoe Covers, Gloves Floor Mats, and Cleaning Supplies for Grow Rooms

There are many affordable and field proven advantages for cannabis growers who adopt technology found in nearly every controlled agriculture or biotechnology environment. Here a few organic contamination control methods and products that reduce the…

- Andersen Mat Solutions for Healthcare

The Andersen Company is a producer of high-quality, dependable mats for indoors and outdoors. This post is dedicated Healthcare Solutions. Interior Mats Interior mats perform many tasks. They are useful as dust control or finishing…