#1. Solder at Lower Temperatures

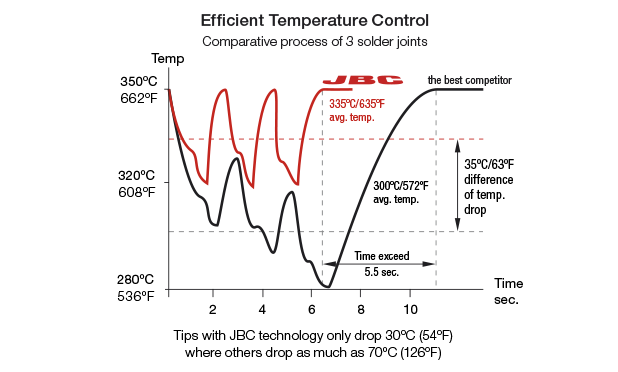

The combination of High-Power Mass Ration Tips and an Integrated Heater / Thermocouple delivers lower soldering temperatures and the best thermal recovery in the market.

- JBC technology means tips only drop 30ºC (54ºF), where others drop as much as 70ºC (126ºF).

- This innovative technology allows a reduction of the temperature by at least 50ºC (90ºF).

- Lower temperatures reduce the risk of damaging components and improves quality of soldering and desoldering.

#2. Faster Temperature Recovery

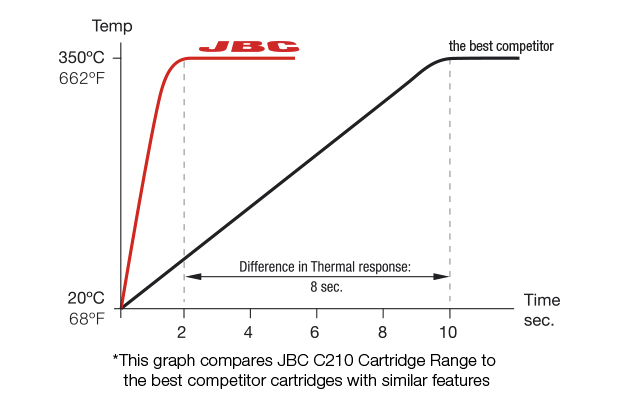

JBC’s Exclusive Heating System recovers tip temperature extremely quickly. This increases work efficiency, and allows the user to work with lower temperatures.

JBC Systems can reach 350ºC (662ºF) in as little as 2 seconds. Other stations on the market can take 10 to 90 seconds.

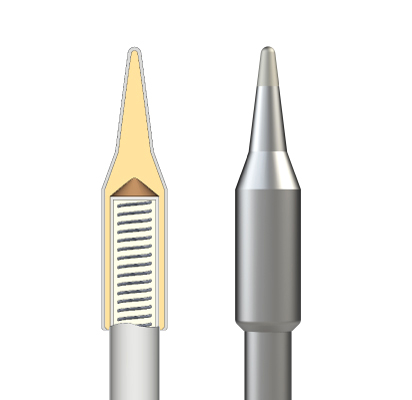

The compact element optimizes heat transfer by reducing the thermal barriers.

A fully-integrated thermal sensor works with the heater to ensure extremely quick temperature recovery.

#3. 5x Longer Tip Life

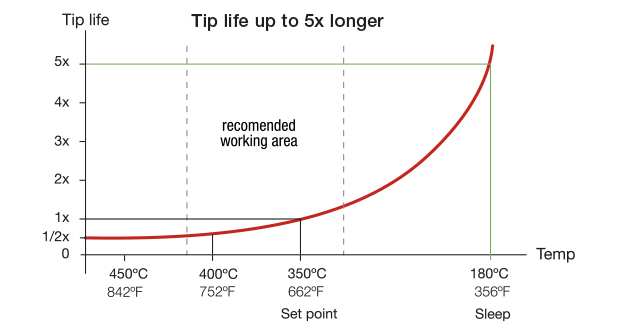

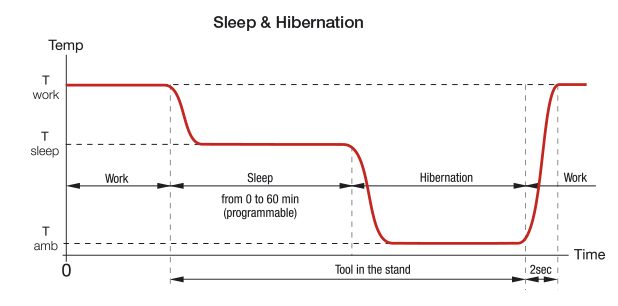

Thanks to automatic detection of the tool in the stand, JBC Soldering and Rework Stations enter into Sleep & Hibernation mode when not being used. As a result, tips lasts up to 5 times longer.

Longer Tip life

Tip life increases exponentially by using lower temperatures, as shown. Using Sleep Mode, the temperature is further reduced, which extends tip life by 5x.

Sleep Mode

Sleep Mode automatically lowers tip temperature below the solder melting point when the tool rests in the stand. It prevents the dissolution of the tip’s iron coating into molten solder.

Hibernation Mode

After a configurable period of tool inactivity in the stand (10 min factory default), the tool enters into Hibernation Mode. It cuts off the power supply, allowing the tip to reach room temperature, thus preventing oxidation and saving energy.

Factors that Limit Tip Life

Flux and Solder Alloy

Too much active flux can cause corrosion. IPC recommends: ROL, REL and ORL. The internal flux from small diameter solder reels might not be enough. Provide compatible external flux if necessary.

Oxidization

Iron oxide does not wet nor transfer temperature well (dewetting). The higher the temperature, the greater the risk of oxidation. Keep tips always tinned while not in use. Use flux on your solder joints. Take advantage of Sleep & Hibernation functions.

Iron Plating Thickness

Plate wear shortens tip life (hollowed-out). Do not use mechanical of chemical means to clean the tip. Use the cleaning methods provided by the manufacturer. Do not apply too much pressure to the tip.

Incorrect Techniques

Too much pressure on the surface to solder can cause tip or plate breakage. Do not use as a pointed object or a screwdriver. Choose the biggest tip possible for each application and work at the lowest possible temperature.

Working Temperatures

The higher the temperature, the greater the oxidation and corrosion. Work with the lowest possible temperature. Use thermal efficient tools and keep tips clean of oxidation.

#4: Increase your Productivity

Easily change your tips! Just place your tool in the compatible tool holder, pull, and insert the new tip. This reduces your idle time while increasing operator safety.

- Increase productivity by using the quick cartridge extractor, which is available in all Stands and Compact Stations.

- This JBC-designed system allows the user to change cartridges quickly and safely.

- Without switching the station off, you can carry out different soldering jobs in just few seconds.

Save time by using the quick cartridge extractor in a fast and safe way!

#5: Over 500 Cartridge Shapes

The essential part of the soldering iron is the tip. For this reason, JBC offers a broad selection of cartridges of different sizes and shapes to choose from, specific to your soldering or rework job.

JBC has developed the most advanced cartridges with the following features:

- Excellent Heat Transfer

- Instantaneous Heating-Up

- Superior Durability

#6: Ergonomic Tools Designed for Comfort

JBC’s wide range of tools feature soldering and rework irons that guarantee maximum efficiency.

The short distance tip-to-grip allows you more control and the highest precision.

JBC tools are currently the smallest, the lightest and the most ergonomic on the market.

#7: Modular Systems – Get Only What You Need

Build a personalized station that is specific to your soldering or rework needs.

All control units incorporate JBC’s exclusive heating system that increases work efficiency thanks to tip fast temperature recovery. To create a complete, working system, simply select: a control unit, stand, tool, and cartridge.

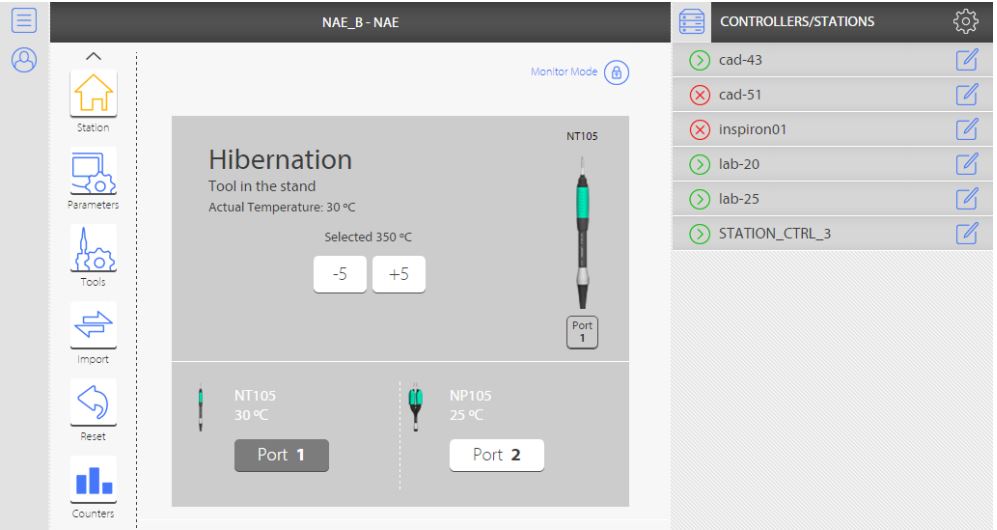

#8: Easy-to-Use Menus

JBC’s User-Friendly Menus allow you to personalize over 20 parameters to help manage your soldering process. Set temperature limits, check usage counters, lock the station with a PIN or program Sleep & Hibernation features.

Station Configuration

Set the station parameters according to your work needs and personalize the new functions

Tools Preset

Set the tool configuration. The settings are independent for each tool type and port.

Partial Counters

Display the cycles and the time worked.

Graphics

Analysis of the soldering process It helps you select the best tip for your work and see the quality of each soldering joint. Monitor your work with power and temperature data in real time!

#9: PC Communication Station

Communication Station is a web manager which allows you to manage JBC soldering stations from your PC. This solution allows you to access station data remotely, using the company network and/or internet from any device, smartphone, tablet, Android, iPhone/iPad or computer.

#10: Constant Innovation

More than 80 years of experience have placed JBC at the technological forefront of tools for soldering and rework operations in electronics.

Innovation, efficiency and reliability are the key features of a wide range of products which have been designed to satisfy the most demanding requirements of professionals.

The R&D department at JBC has created the most innovative soldering technologies that factor in your company’s needs.

JBC has a solution for those who want full traceability of their processes during manual soldering operations, providing tools to control, monitor and trace the soldering process of JBC Stations.

Related Posts

-

Why Do I Need Fume Extraction?

There are many applications where fume extraction is necessary and/or required by law. Manufacturing and assembly operations, repair centers, salons, ect. Anywhere where there are harmful fumes and particles in the air that can be…

- Metcal MX-5000 Soldering System

The new MX-5000 Series Soldering & Rework System is the next generation of the trusted Metcal Soldering Systems that will enable you to increase productivity and process control for a wide range of applications with…

-

A Compact Review of Weller's WT Soldering System

According to Weller, the WT soldering stations represent the world’s first soldering system with replaceable, passive, high-performance soldering tips.

-

Everything You've Ever Wanted to Know About Soldering

We ran into this fantastic soldering demo on YouTube using PACE equipment. View Production Automation's YouTube Channel View all the PACE products Production Automation offers

- Hakko FX-888 Soldering Station

Continuing on our Hakko product focus, today we'll look at the Hakko FX-888 Soldering Station. Please keep in mind that the items that were blogged yesterday, and the rest of the Hakko products that will…

-

Why Do I Need Fume Extraction?

There are many applications where fume extraction is necessary and/or required by law. Manufacturing and assembly operations, repair centers, salons, ect. Anywhere where there are harmful fumes and particles in the air that can be…