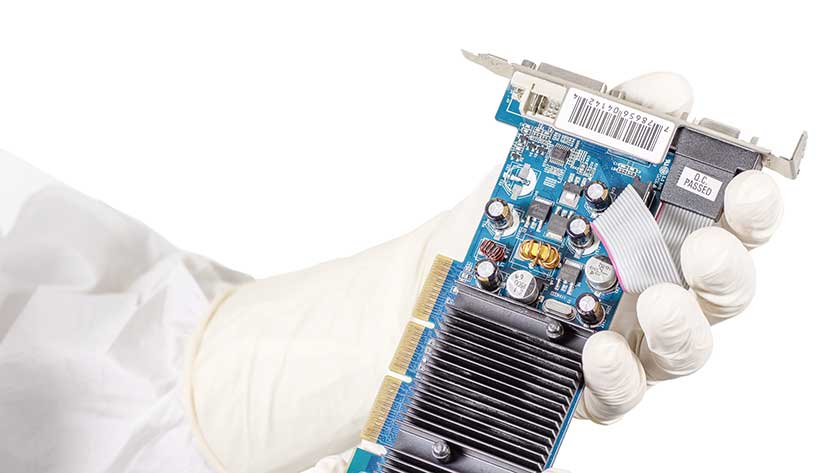

ESD protection should be worn whenever handling items sensitive to electrostatic discharge. Complication often arises when a glove requires both clean use and safe levels of surface resistance. Manufacturing processes often produce residues such as NVRs (non-volatile residues) that impede electrical conductivity. Meanwhile, dedicated ESD fabrics are often not viable for cleanroom use, as they tend to shed particulates at a much higher rate than latex, nitrile, or vinyl gloves. The proper ESD cleanroom glove selection often requires a process of elimination depending on the process. Here, we’ll provide a synopsis of glove performance for cleanrooms. (See PDF)

Read More: Ansell ESD & Cleanroom Gloves

How Does Cleaning a Glove Impact It’s ESD Properties?

Contaminants generally make a glove more electrically conductive by increasing the mobility of ions on the surface. High-humidity with significant moisture content also increases conductivity. Glove cleaning can unknowingly remove a significant degree of ESD protection.

Vinyl or Latex? The Ideal Cleanroom ESD Glove?

A clean glove with the proper ESD protection is often difficult to find. Test results indicate that most low-residue gloves with proper cleanliness for a cleanroom also show insulative characteristics. While vinyl gloves often show the most favorable static prevention properties, they should avoid cleanrooms because of high NVR (non-volatile-residue). Studies show that increased levels of NVR associate with a decrease in surface resistance. The alternatives indicate that nitrile provides a great combination of static dissipation compared to vinyl or latex.

Can I Use Cloth Gloves in an ESD Protected Cleanroom?

While cloth gloves provide adequate static dissipation, a cloth glove is prone to shedding. Materials that shed particulates, especially in the immediate vicinity to sensitive processes should not be used in a cleanroom environment.

However, these contaminants make the glove material more electrically conductive by increasing ion mobility on the surface, especially at higher humidity where there is more water available for adsorption. Therefore, by cleaning the glove, the manufacturer (perhaps unknowingly) removes a significant element of the ESD protection.

The Ideal Cleanroom ESD Glove?

The ideal “ESD clean” glove is chemically bonded with an additive integrated into its base polymer, referred to as ‘inherently dissipative’ materials. The surface materials provide a clean outer surface, while internal materials maintain proper electrical conductivity. Future technology may support pliable and soft dissipative polymers in the future, but today a clean nitrile glove is most common for cleanroom use.

Vinyl gloves provide ideal electrical resistance, its NVR values ordinarily exceed that of products found in a cleanroom. Therefore, a clean, nitrile glove is the most common recommendation. A high-quality, latex-free glove manufactured for ESD handling is important. This ensures that resistivity remains stable from batch to batch.

All of our ESD gloves and ESD cleanroom gloves provide a selection from hand-picked manufacturers. Like any glove, the ideal option depends on many factors: temperature, operator risk, product sensitivity, dexterity, and more. Each of our ESD gloves is hand-picked from top manufacturers. Each shipment maintains tight tolerances with minimal deviation in physical or electrical properties.

Our customers regularly test our cleanroom gloves for surface resistivity as part of their ESD control programs. During field testing, the resistivity failure rate of a high-quality ESD nitrile glove is extremely rare. We’ve never fielded any reports of a nitrile glove failing ESD testing requirements with proper use and storage. In the case you need help selecting the right glove for your use, we have a number of static control experts on staff to answer any questions. Contact us every business day by phone, email, or web chat via our online store and we’ll get back to you within 24 hours.

Compare top brands and get bulk discounts. We’re your static control and cleanroom experts.

Related Posts

-

Ansell Gloves: Hyflex, Nitrile, ESD and Cleanroom

View the newest Ansell gloves for cleanroom, general purpose, chemical protection, and static control.

-

CleanPro® Softwall Cleanroom Enclosure

This customer needed to enclose a piece of machinery, and CleanPro® was able to provide a solution.

-

CleanPro® Turnkey Cleanroom Install

CleanPro’s turn-key cleanroom solution provided a one-stop, one-contact result for the initial delivery and on-site installation of walls, ceiling grids, electrical systems, flooring, filters, HVAC, and more.

-

CleanPro® Chemotherapy & CSP Cleanroom Installation

This modular, sterile compounding cleanroom is designed for USP 797 and USP 800 compliance, particularly for compounding chemotherapy drugs. Safe handling of sterile compounds requires special considerations: heat-welded floors, anterooms and buffer areas.

-

Where to Buy Cleanroom and ESD Garments, Protective Gear, and Labwear

Worklon® provides a comprehensive line of apparel for cleanrooms, controlled environments and ESD sensitive areas. Markets served include Pharmaceuticals, Automotive, Semi-conductor and Food Processing. Worklon® manufactures cleanroom and controlled environment apparel and accessories for the…

-

Ansell Gloves: Hyflex, Nitrile, ESD and Cleanroom

View the newest Ansell gloves for cleanroom, general purpose, chemical protection, and static control.