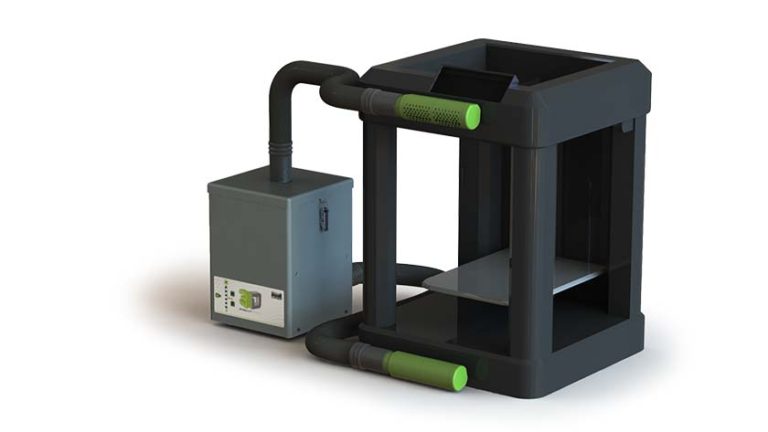

BOFA Fume Extractors for 3D Printing

3D printers are known to produce a number of byproducts during operation. Common 3D printing filaments such as ABS and PLA are known as high emitters of ultra-fine particulates (UFPs), while nylon and PCTPE are known for high levels of volatile organic compounds (VOC) concentrations. Once airborne, particles and noxious fumes are easily absorbed into the lungs where they can enter tissues and cells.