Table of Contents

How to Get Cleaner Finishes and Remove 3D Printed Support Material Faster

High-quality 3D printed parts overcome numerous construction and design barriers for outstanding results. 3D printing support materials allow for thermoplastics to set while an additive build is in the process of extruding and cooling. Tech-forward equipment such as ultrasonic cleaners and ultra-pure solvents such as acetone and isopropyl alcohol are critical for highlighting detail and surface finish, especially when removing support material. So what is support material, exactly?Support Material Basics – What Is It?

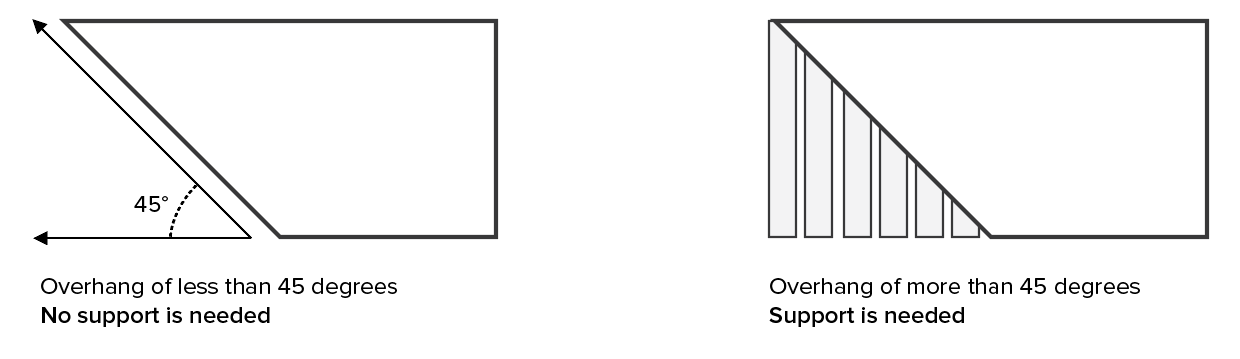

Gravity is a crucial consideration for the success of any 3D printed part. Support materials and structures ensure that extruded filament remains in its intended shape and form during the build and cooling process. With FDM 3D printing, support materials enable structures with an overhang of over 45° degrees.

Support Materials Technologies and Applications

Traditionally, removing support was messy. Binder based applications resembled something closer to archeological excavation rather than advanced prototyping technology. Removing the support material was wasteful and time consuming.

Snap-fits, hinges, and threaded fasteners require tight tolerances for functionality, therefore removing support material cleanly and thoroughly is potentially tedious, laborious, and time consuming.

Today, there are two popular types of support material technologies used by the majority of 3D printers; one type is broken or cut away by hand like a kit-kat bar (HIPS) and the other in which the material is soluble (see below) and dissolved in a chemical or water-based bath. FDM, SLA, DLP, and material jetting all rely on support structures for complex architectures, each with slightly different processing and support material availability.

Soluble Support Materials

PVA (used with PLA), HydroFill (used with ABS), Infinity (3D Systems) and SUP 706 (FDM & PolyJet) are among the most popular 3D printing materials that easily break apart after exposure to water. Soluble support materials enable the hands-free removal of support material with minimal manual scrubbing or abrasive brushing. The advantage of soluble support material is dually functional: it does not require extensive human labor, therefore it not only saves time, but it extends the design freedom by standardizing the delicate processing of complex parts with internal cavities, lattice structures, and microstructures. It is soaked in warm water, and then the support material rinses off.

The downside of the soluble support is that it can take quite some time for the material to dissolve before it is ready for removal. The more extensive and dense the support material, the longer the process takes. Traditionally, water jets and chemical baths improved speed to removal, but often sacrificed intricate detail, increased potential for damage, and added overhead for chemical baths and waste disposal.

Ultrasonic cleaners have remodeled the traditional path to finishing and processing 3D printed parts with autonomous function and clock-like consistency. Likewise, a many other historically simple products, like specially formulated wipes and solvents from pure and high quality materials, help exceed benchmarks for final quality with faster workflow.

Ultrasonic Cleaners

Ultrasonic cleaners provide a clean, safe, quiet, and consistent outcome for post-processing 3D printed parts with soluble support materials. The gentle vibrational frequencies ensure that cleaning reaches within small geometries, internal cavities, and between build layers so that each section achieves the smoothest possible finish with the least risk of damage caused by handling, scrubbing, or brushing. Warm solvents speed up dissolving time and ensure a smooth surface where contact material is in contact with the part, which makes heated ultrasonic cleaners ideal for 3D printed pieces. For some the large tank volume of a commercial ultrasonic cleaner is essential for extra large parts, smaller benchtop versions provide an economical option for any 3D printing professional or enthusiast.

Low-Lint Wipes for 3D Printing

The cleanroom wipe is historically the most effective and commonly used tool for the removal of contaminants, particulate, and residual material in critical manufacturing, production, and pharmaceutical compounding environments. Low lint wipes provide a number of advantages for post processing 3D printed parts. The reason low lint wipes are used in cleanrooms is for mitigating the spread of contaminants through shedding and unraveling. Ordinary paper towels or rags easy fall apart, create lint and particulate, and rip when cleaning crevices or abrasive edges. Low resolution FDM builds with wide angles, increased layer heights, and complex support or lattice structures benefit from a wipe that won’t tear and leave particles behind within crevices. Heavy-duty woven polyesters provide extreme durability, and reduce exposure of parts to chemical substrates which manifest during the manufacturing process of traditional wipes.

The cleanroom wipe is historically the most effective and commonly used tool for the removal of contaminants, particulate, and residual material in critical manufacturing, production, and pharmaceutical compounding environments. Low lint wipes provide a number of advantages for post processing 3D printed parts. The reason low lint wipes are used in cleanrooms is for mitigating the spread of contaminants through shedding and unraveling. Ordinary paper towels or rags easy fall apart, create lint and particulate, and rip when cleaning crevices or abrasive edges. Low resolution FDM builds with wide angles, increased layer heights, and complex support or lattice structures benefit from a wipe that won’t tear and leave particles behind within crevices. Heavy-duty woven polyesters provide extreme durability, and reduce exposure of parts to chemical substrates which manifest during the manufacturing process of traditional wipes.

Pre-saturated isopropyl alcohol wipes provide a convenient way to wipe down parts quickly and with less exposure to volatile aerosol particles and minimal chemical adulterants. A neutral, non contaminating wipe is essential for SLA or multi-material parts in which the final texture and finish is paramount for a quality aesthetic. Abrasive wipes or chemical substrates may dull or discolor the final finish. Likewise, lint fabric could adhere or mesh to the parts surface when finishing with solvents like acetone, which is avoided with non-shedding wipes.

Sterile isopropyl alcohol wipes are ideal for the support of dental 3D printing. Parts that come in direct contact with tissue or mucous membranes such as drill guides, abutments, and molds drive the growing need for 3D printed materials free of pathogenic microbes or other contaminants. Learn more about sterile 3D printing applications

Read More: Low Lint Wipe Buyers Guide

Autoclaves and Sterilization of 3D Printed Parts

One of the most demanding and intensive sterilization processes is autoclave sterilization. For many consumer-based 3D printed materials, the pressure and heat associated with autoclave cycles would quickly warp, melt, or compromise the tensile strength and shape of 3D printed parts. Autoclave heat cycles yield one of the most effective tools for sterilizing 3D printed parts and other thermoplastics. Methods such as ETO and Gamma sterilization often compromise the integrity or luster of the final part, but many 3D printed materials show promising integrity.

Cleaning 3D Printed Parts with Isopropyl Alcohol & Solvents

99.8% pure anhydrous (containing the least water possible and no denaturant) isopropyl alcohol is excellent for tape head cleaning, defluxing, stencil cleaning, other light cleaning, and as a flux thinner. Avoid “bargain” alcohols for critical electronic cleaning. Cheap alcohols contain much more water, which slows drying and can cause oxidation, while “denatured” alcohols leave residues.

99% isopropyl alcohol (IPA) is ideal as a solvent for cleaning 3D printed parts, extruders, print bed trays and removing support material. USP-Grade, 99% IPA provides the lowest presence of adulterants and is free from denaturants with minimal water content. A more aqueous solution, such as 70% IPA may be ideal for non-hydrophilic printing filaments. Increased water content prevents drying out and reduces reapplication of solvent.

Polishing and Cold Welding with Acetone

Acetone is another valuable 3D printing solvent. It is ideal for vapor smoothing, cold welding, and ideal for preparing parts for painting. Acetone dissolves layer lines and improves paint adhesion with minimal sanding. The overall result is an increase in surface detail without the loss of delicate or subtle features. Cold welding adheres 3D printed parts without adhesive or sanding by applying a thin layer of solvent. For PLA parts, acetone generates a sufficient bond for mock prototypes or reconnecting pieces that broke off post-print.

Related Posts

-

Filament Storage Cabinets for 3D Printing

Notably, filaments such as nylon may absorb unacceptable amounts of water in the short period of time they are on the printer. This cabinet provides active feedports for use during prints, and long term storage…

-

BOFA Fume Extractors for 3D Printing

3D printers are known to produce a number of byproducts during operation. Common 3D printing filaments such as ABS and PLA are known as high emitters of ultra-fine particulates (UFPs), while nylon and PCTPE are…

-

Filament Storage, Dry Boxes and Spool Cabinets for 3D Printing

Are you ruining your 3D printing filaments by baking them? What's the best way to dry FDM and PLA filaments? What about Nylon and PLA?

-

3D Printing Fume Extractors for Odors and Particles

Does a HEPA filter capture ultrafine particles (UFPs). What toxins does 3D printing produce? Why should every 3D printer have both a activated carbon and HEPA filter?

-

Sterile 3D Printing Materials for Medical Devices

Is sterile 3D printing possible? Are 3D printed parts sterile? This comprehensive guide to 3D printing sterile parts provides materials that withstand various sterilization techniques such as autoclaving, heat, ETO, and gamma. Here's how 3D…

-

Filament Storage Cabinets for 3D Printing

Notably, filaments such as nylon may absorb unacceptable amounts of water in the short period of time they are on the printer. This cabinet provides active feedports for use during prints, and long term storage…