Why Is This the Best 3D Printing Filament Storage Solution?

StatPro is known for its high-end desiccant dry cabinet technology used for humidity and temperature control in cleanroom and electronics manufacturing. These filament dry cabinets are designed specifically for storing 3D printing filament and support materials at a price anyone with a 3D printer can afford.

See the Difference in 3D Printing Quality Between Dry Cabinet Storage and Room Air

For DIY and commercial applications that require large quantities of filaments spools, dry cabinets are a cost-effective option that eliminates baking completely. This PDF demonstrates the differences in print quality when printing with water saturated vs completely dry filaments.

Tested Results and Outstanding Humidity Control

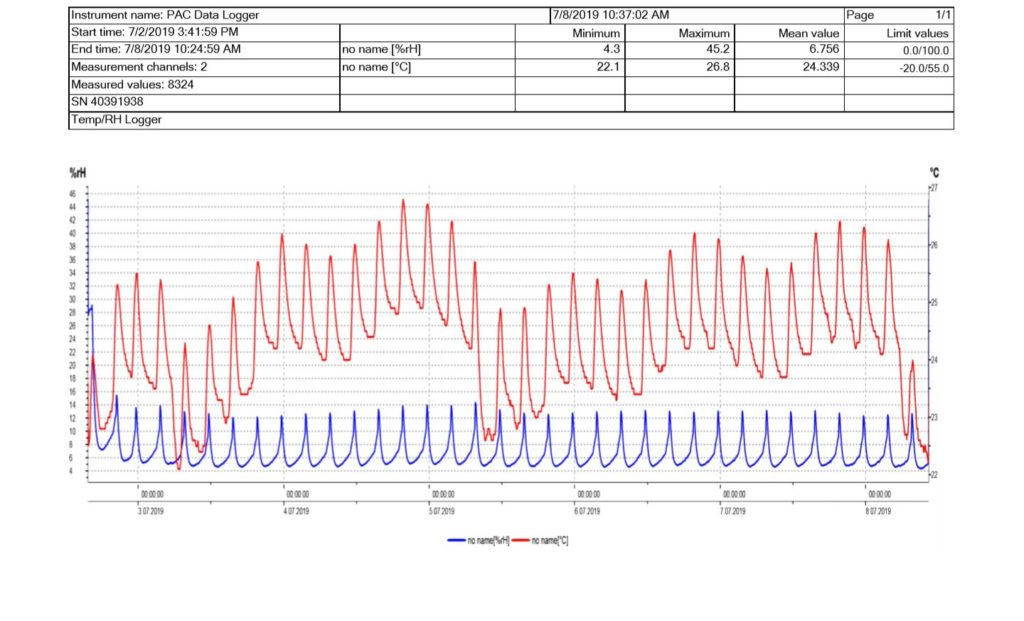

We’ve tested these cabinets in-house with a data logger. Below you can see temperature in red, and relative humidity readings in blue. Importantly, the overall humidity is not affected by temperature. Changes in ambient temperature, such as turning off the AC or heat/cold nearby will not have an meaningful impact on the conditions within the cabinet. In the example below, you can observe how AC on/off the ambient temperature over the course of a few days.

The maximum RH level (22%) reflects the initial conditions before it was closed. The RH then hovers between a max of ~12-14% RH, and reaches as low as 4% RH. The gauge itself slowly adjusts to cabinet conditions, thus usually remains around ~10%. However, the actual readings within the cabinet are reflected below in blue. These results will vary based on the number of spools, sizes, and amount of moisture, but ultimately will provide a perfect environment for long-term storage and active use.

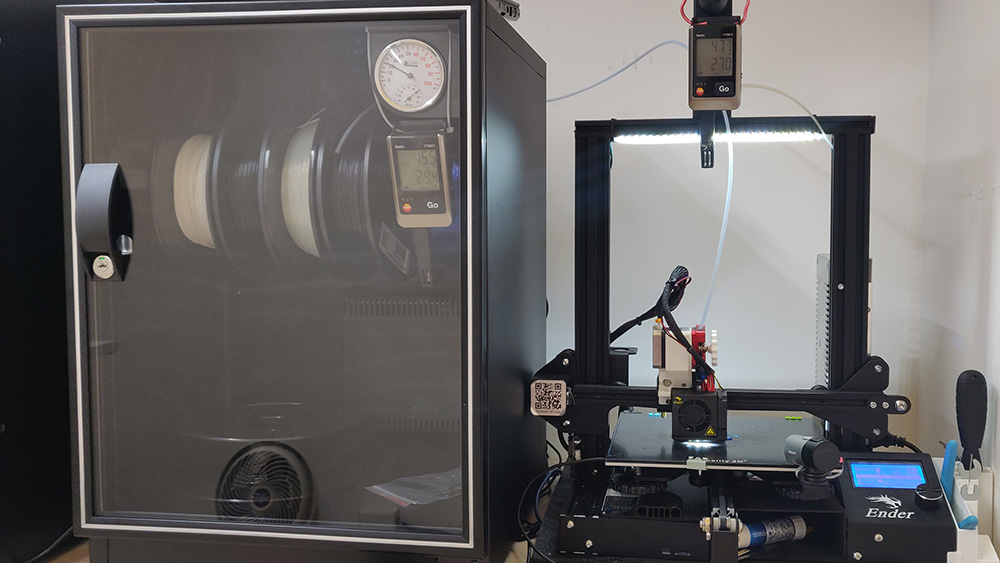

Automatic Humidity Control & Feeder Ports

Automatic humidity controlled cabinets provides a quick and simple way to store filament without hassle. Better yet, the feeder ports allow you to feed your 3D printer without ever opening the cabinet. Simply set the desired humidity level, store the filaments and the dehumidifier will take care of the rest. Your filament stays dry, accessible, identifiable, and ready to be used anytime you need them for a print.

Standalone Hygrometer and Filament Feeder Ports

- Fully Adjustable Spool Hanger

- Standalone Hygrometer for Active Monitoring

- 4-Filament Feed Ports for Direct Printing

- Fast 2-Hour Recovery

Benefits of using a Filament Dry Cabinet

- <10% ±5% RH: Optimal for all filament materials

- Convenient: No consumable parts

- Low Energy Consumption: 13W Avg. / 100W Max.

- 4 Filament Feed Ports: Prints while in dry storage

Traditional Dry Method Disadvantages

- Oven Baking: High energy costs, decreases tensile strength, time-consuming, melt filament if too hot

- Desiccants: No RH control, constant replacement, and maintenance

- AC & Dehumidifier: High energy cost, unable to reach below 40% RH, ineffective in low temperatures

- Other Filament Dryers: Constant heat baking with high energy consumption, unable to dry for extended periods, only able to dry a few spools at a time

Read More: 3D Printer Filament Storage: Is Humidity A Silent Killer for 3D Printed Parts?

Does this Cabinet “Dry” Filament?

While saying this cabinet “dries” filament isn’t technically false, it’s important that the intended function is clear. It’s not designed as a replacement for rapidly heating filament and baking out moisture at high temperature.

You Won’t Replace Baking…You’ll Avoid it Completely

Notably, filaments such as nylon may absorb unacceptable amounts of water in the short they are on the printer. This cabinet provides active feedports for use during prints, and long term storage between cycles. By simply removing your filaments from the factory sealed packaging and placing them into the cabinet, you’ll avoid any baking or saturation completely.

What if my filament is already saturated?

Items stored in a low humidity environment will eventually dry out, but there are no specific metrics for this process. Depending on the material and saturation level, these figures vary. In most cases, it takes too long to be considered a viable production drying solution. Quickly removing moisture from filament likely requires active heat.

Notably, filaments such as nylon may absorb unacceptable amounts of water in the short period of time they are on the printer. This cabinet provides active feedports for use during prints, and long term storage between cycles. By simply removing your filaments from the factory sealed packaging and placing them into the cabinet, you’ll avoid any baking or saturation completely.

If a 3D printing filament storage prevents one failed build of 80+ hours with expensive engineering grade thermoplastics, starting at only $222, a filament dry cabinet has already paid for itself.

StatPro 3D Filament Storage Cabinet Features

- <10% ±5% RH Low Humidity Storage

- Fully Adjustable Spool Hanger

- Standalone Hygrometer for Active Monitoring

- 4-Filament Feed Ports for Direct Printing

- Fast 2-Hour Recovery

Related Posts

-

Filament Storage, Dry Boxes and Spool Cabinets for 3D Printing

Are you ruining your 3D printing filaments by baking them? What's the best way to dry FDM and PLA filaments? What about Nylon and PLA?

-

BOFA Fume Extractors for 3D Printing

3D printers are known to produce a number of byproducts during operation. Common 3D printing filaments such as ABS and PLA are known as high emitters of ultra-fine particulates (UFPs), while nylon and PCTPE are…

-

3D Printing Fume Extractors for Odors and Particles

Does a HEPA filter capture ultrafine particles (UFPs). What toxins does 3D printing produce? Why should every 3D printer have both a activated carbon and HEPA filter?

-

Sterile 3D Printing Materials for Medical Devices

Is sterile 3D printing possible? Are 3D printed parts sterile? This comprehensive guide to 3D printing sterile parts provides materials that withstand various sterilization techniques such as autoclaving, heat, ETO, and gamma. Here's how 3D…

-

How to Remove 3D Printing Support Material Faster and Improve Final Quality

What's the easiest and fastest way to clean 3D printed parts with soluble support materials or standard support materials like HIPS and PVA? Here's how to clean the reaches of 3D printed parts including small…

-

How Dry Cabinets Solve Moisture Problems During SMT Reflow

An Alternative Drying Solution Replaces Traditional Methods As the industry utilizes a high-temperature reflow process, moisture sensitivity in SMT remains a constant problem. Serious manufacturing defects and failures are much more likely to occur later…