USP 800 Cleanroom Design – Negative Pressure Changes and Requirements

What equipment and engineering controls do USP 800 cleanrooms require? What types of storage and monitoring systems will I need?

What equipment and engineering controls do USP 800 cleanrooms require? What types of storage and monitoring systems will I need?

A gowning room has many variables. There is no mathematical formula when determining the features, surfaces, and HVAC requirements best suited for your application. Space requirements, volume of operators, aseptic workflows, material choice, and even aesthetics all factor into design considerations. Most facilities benefit from contacting a controlled environment specialist who can identify critical product sensitivities, storage requirements, and operational standards.

For communication satellites that remain within earth’s orbit, an ISO Class 6-8 cleanroom allows sufficient particle and contaminant control. Cleanroom engineers design each space so that particles from production surfaces are whisked away from critical components. A combination of softwall production areas and hardwall cleanroom facilities provide isolation of critical tasks.

Pre-engineered fabrication consolidates scheduling with minimal disruption and fewer variables. Difficult or expensive upgrades avoid overbearing noise, construction artifacts, and minimize if not eliminate the burden on facility staff for project management.

New USP guidelines may present challenges for compounding facilities. Some facilities need infrastructural and mechanical modifications for compliance. System evaluation includes duct systems, HEPA fan filters, differential pressure standards, air monitoring, and external air exhaust equipment.

Definitive Cleanroom Construction FAQ: How much does a cleanroom cost? How does the level of ISO classification impact build and operating costs? How much supporting space will I need for a cleanroom addition or ISO class upgrade? What’s the advantage of a turnkey cleanroom system?

CleanPro Critical Environment Monitoring Solution:Get real time reporting, alarm conditions, and instant traceability. CleanPro’s Monitoring Solutions are sophisticated computer-based monitoring systems for critical applications. They

Article reprinted from Clean Air Products, manufacturers of air showers, cleanrooms, and cleanroom accessories. A cleanroom provides a controlled environment in which companies can produce

What are the key determinants of cleanroom components? Learn about different types of cleanroom filtration, wall construction, lights, temperature, humidity and more.

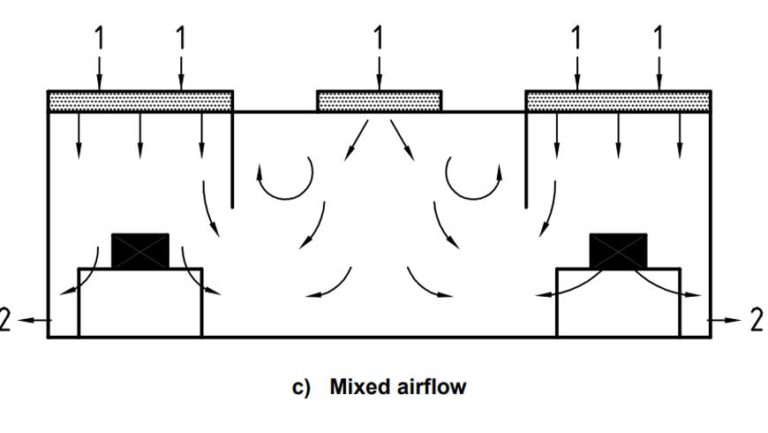

A cleanroom air handling unit (AHU) is a cornerstone of temperature, humidity, and pressurization within controlled environments. Today, modular fan filter units allow more adaptable configuration with simplified maintenance procedure. Both systems serve conditioned and filtered air throughout a cleanroom facility.

When Should I Replace a Cleanroom Fan Filter? Pre-Filter Replacement Pre-filter media should be replaced every six months and inspected regularly. Pre-filters in gowning rooms

Why Can’t Anyone Agree on Benchmarks for Cleanroom Air Change Rates? There are a number of best practice guides and benchmarks for cleanroom air change