You may be asking yourself “What exactly is a desiccator cabinet, and why would I need one?”

The answer to the first question is easily definable;

Desiccators are sealable enclosures containing desiccants used for preserving moisture-sensitive items. A common use for desiccators is to protect chemicals or materials which are hygroscopic or which react with water from humidity.

The answer to the second question is more in-depth, the use of desiccator cabinets depends solely on your needs and products. Much of today’s high-tech manufacturing requires extensive use of integrated circuits and other sensitive devices and sub assemblies. These packages are very durable but when stored in a typical manufacturing environment they become exposed to contaminants and moisture in the atmosphere causing corrosion and oxidation on the leads. The ultimate results can be poor solder contact and possible board failure.

The answer to the second question is more in-depth, the use of desiccator cabinets depends solely on your needs and products. Much of today’s high-tech manufacturing requires extensive use of integrated circuits and other sensitive devices and sub assemblies. These packages are very durable but when stored in a typical manufacturing environment they become exposed to contaminants and moisture in the atmosphere causing corrosion and oxidation on the leads. The ultimate results can be poor solder contact and possible board failure.

There is your outline for needing a desiccator cabinet in your facility. Do you have sensitive products that can be easily damaged by humidity? Have you experienced your products failing inspections due to environmental damage? A desiccator cabinet would help maintain the integrity and quality of your sensitive components.

Production Automation carries only the highest quality of Dessicator Cabinets from the D.M. Semiconductor Company (DMS). DMS was established in 1963 and has a long history of servicing the electronics, defense and medical industries. Starting in 1979 DMS started producing small 1, 2 and 3 door acrylic desiccator cabinets and now manufactures, in the USA, a full line of quality desiccator cabinets.

DMS desiccator cabinets provides clear, clean moisture free storage. A mini-cleanroom isolated from the typical warehouse and manufacturing atmosphere. A cleanroom environment at a fraction of the cost. The input of nitrogen or compressed dry air into the cabinet displaces the contaminated air and provides a truly ideal clean, dry space for your components and devices. Due to reduced moisture within the cabinets, electrostatic charge becomes an issue for which DMS offers a permanent, transparent ESD coating which is applied in the manufacturing process. Grounded stainless steel bottom plates and shelving systems complete the ESD protection process.

Production Automation carries DMS’s full line of desiccator cabinets, making it easy to find a unit that will work best in your application:

Single Tier

- Solid Wall Non-ESD Acrylic

- Plenum Wall Non-ESD Acrylic

- Solid Wall ESD Acrylic

- Plenum Wall ESD Acrylic

Two Tier

- Solid Wall Non-ESD Acrylic

- Plenum Wall Non-ESD Acrylic

- Solid Wall ESD Acrylic

- Tier Plenum Wall ESD Acrylic

Related Posts

-

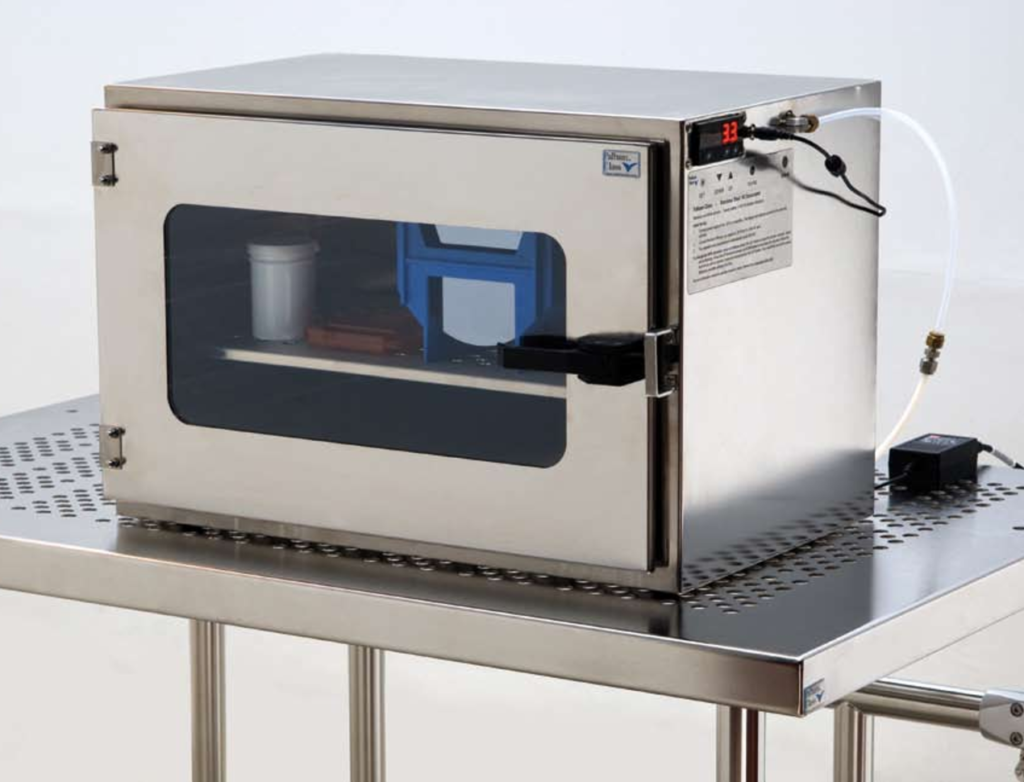

Palbam Class N2 Desiccator Cabinets

Palbam Class Stainless Steel Cleanroom Desiccator Cabinets Palbam Class developed its first desiccator cabinets for the Semiconductor Industry. Due to the demands of this industry all the cabinets are manufactured from the cleanest materials possible.…

-

Self-Refreshing Nitrogen-Free Desiccator Cabinets

CleanPro Cabinets are designed and manufactured to be able to maintain an environment of

-

How Dry Cabinets Solve Moisture Problems During SMT Reflow

An Alternative Drying Solution Replaces Traditional Methods As the industry utilizes a high-temperature reflow process, moisture sensitivity in SMT remains a constant problem. Serious manufacturing defects and failures are much more likely to occur later…

-

The Hidden Costs of Acrylic Enclosures, Cabinets, and Desiccators

Why Is Static Dissipative PVC a Better Option than Acrylic?

-

Filament Storage Cabinets for 3D Printing

Notably, filaments such as nylon may absorb unacceptable amounts of water in the short period of time they are on the printer. This cabinet provides active feedports for use during prints, and long term storage…

-

BenchPro Pre-configured Drawer and Tool Cabinets

What makes BenchPro one of the best cabinets available online? BenchPro cabinets, drawers, and accessories are guaranteed for 25 years of use with up to 200 lb. drawers. These pre-configured cabinets allow simple purchasing for…