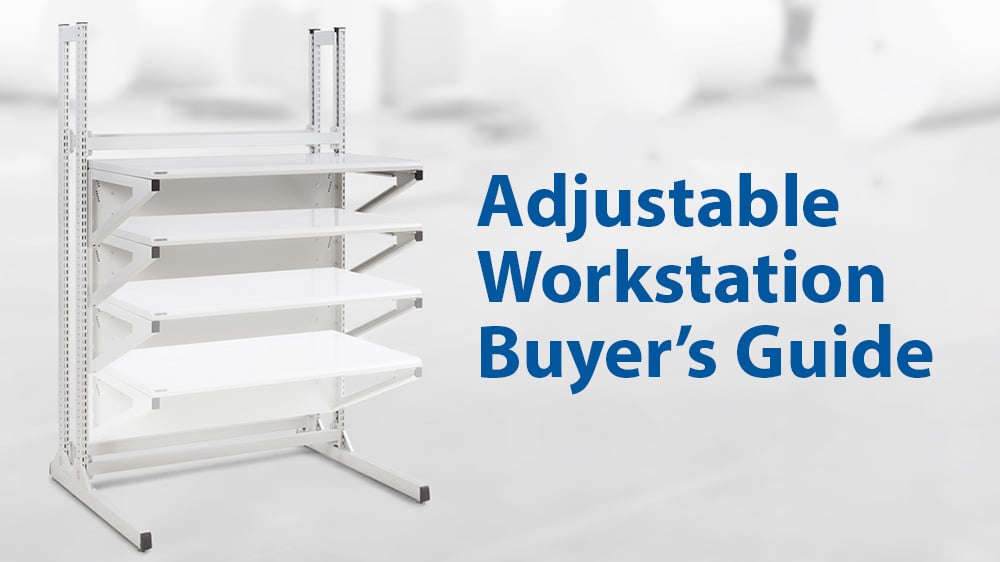

The current market provides consumers with a diverse variety of workstations from different brands and suppliers. Most may be suitable for shipment or office settings, but rarely stand up to the rigorous nature of production settings.

Choosing which workstation is best for your cleanroom or critical manufacturing area can be daunting. One should take careful consideration when selecting a station for a new facility or line layout.

Considerations for Choosing an Adjustable Workstation

Adaptability

When evaluating potential changes or progressions in your workflow, it is essential to take adaptability into account. Some workstations are built-to-order, while others are modular in design and can adapt when necessary.

Dependability

The cost of products and equipment that will be on top of your workstations must also be considered. Workstations not stable enough to hold heavy equipment, machines with moving parts, and unbalanced weight loads can pose serious risk.

Health & Safety

Adjustable workstations can be a significant investment in the health and safety of your operators and engineers through better ergonomics.

What Adjustments are Available?

Tool Adjustment

This type of adjustable workstations allow are perfect for operations that don’t require the work surface to be shifted often.. They allow the end user to keep their options open and flexible when needs can change in the future.

Leg Extenders

Leg extenders can be added to a fixed height, non-adjustable frame. The bolts holding the leg extenders in place can be removed and reinstalled to change the workstation’s height.

Depending on the brand, leg extenders may be included or sold separately. Often, the adjustment ranges are 6” or 12”, in 2” increments, where there are pre-drilled bolt holes. Casters can be added to provide mobility.

Sliding Components

Other workstations use sliding components instead of bolts. The desired height is adjustable with screws, such as this version of Lista’s Align Series.

Other workstations, such as Arlink’s 8000 Series, allow you to remove and replace the worksurface in 3” increments anywhere along support columns.

Manual Adjustment

These stations are fully adjustable through the use of a turning hand crank. The hand crank system gives you all the benefits of an ergo-adjustable workstation, but at a lower price. The handles fold away when not in use, so they don’t create a safety hazard or obstruction in an aisle.

Most workstation manufacturers give the option of your preferred starting height and components that will raise the workstation as much as 12” or 16”. Keep in mind that the mechanisms themselves will need to fit within the legs; there will always be a minimum starting point to fit all components inside the hollow channels of the support structure.

Since hydraulic cylinders extend out from the mechanisms, it’s not conducive to making these components with mobile casters. Their design does not support lateral loads or stress when extended to push them around. To make them mobile, manufacturers of 4-legged workstations with hydraulic height adjustability will use a welded stringer for mounting casters. This allows the casters to come into contact with the floor when in the lowest setting and then raise with the frame as the cylinders extend.

Treston Quick Edge Workstations

One of the most interesting advancements in manually adjustable workstations is an entirely new type of design from Treston. Their new Quick Edge workstations use a spring mechanism to counterbalance the main worksurface. Once you unlock the pins which hold the desired height, you can quickly and easily raise and lower the height from 22”- 54”.

There are no hydraulic lines to get pinched or kinked, and no power is required. These workstations are well suited for areas where frequent adjustment is needed, such as kitting or packaging areas. However, since the worksurface moves independently of the support frame, care is needed when routing power wires, or airlines.

Fully Adjustable

Fully adjustable workstations use a button or rocker switch to raise and lower the work surface. The button can be attached to a motor pump, which takes the place of a crank on a hydraulic system, or could control actuators.

The electronic hydraulic systems are available in many sizes, but since the components themselves take up more room, there are limitations to the size of the footprint. Actuated systems sometimes contain intelligent systems, such as those from Lista Align, which allow for daisy-chaining two workstations together. These stations also have presets that can be used for adjustments between multiple shifts or different processes.

Since these are engineered solutions using telescoping legs and heavy-duty actuators, casters can be placed at the bottom, which makes them one of the very few commercially available adjustable height workstations that are adjustable across the entire height range.

Choose a Workstation That’s Right for the Task

Not all workstations are equal. There are many advantages and disadvantages of the various models available. One type to avoid for production settings is office-grade desks. These use a basic electric motor and drive system designed to carry the weight of items that an operator might need for light office work.

While the low price of some of these stations can be compelling, when you look at overall weight capacities, it’s clear that this type of desk simply will not handle the requirements of cleanroom or critical environment production. This is especially true when performing delicate tasks or when supporting heavy tooling equipment, robotic processes, or microscopes with high magnification.

Adjustable Workstations from PAC

Throughout the years, Production Automation Corporation has had a long-standing relationship with well-known workstation brands, supporting their redesigns and innovations of their adjustable height models. Our customers trust that the adjustable height workstations available through our website are well-built, and have the reliability and product support required when investing in equipment that is directly related to the daily operator’s comfort and workplace efficiency.

Aside from selecting the proper seating and anti-fatigue mats for your work environment, no other product for your production area will have more significance than the right adjustable workstations.

Related Posts

-

10 Reasons to Convert to a Height Adjustable Workstation

Today's workplace is changing. Sitting at a desk all day is no longer acceptable for a workforce wanting more flexibility, increased comfort, and improved health. Sitting all day has proven to be unproductive, uncomfortable, and…

-

ESD Workstation Setup: Grounding & Components

When working on ESD-sensitive projects, whether at home, in a repair shop, or even a large-scale manufacturing operation, having you and your work area fully grounded is a necessity.

-

Wearwell Chemical Resistance Guide

Key A = Performs Well B = Slightly Affected C = Moderately Affected D = Highly Affected U = Not Recommended NT = Not Tested Chemical Urethane Nitrile PVC CFR SBR Natural Rubber Acetone U…

-

Metro Shelving Accessories Buyers Guide

View the Metro shelving accessories buyers guide. We've compiled the entire collection of Metro accessories onto one page for your convenience.

-

Sticky Mat Installation Guide - Placement Tips

Through CleanPro® adhesive sticky mats were designed to be used for cleanroom environments, they can be used wherever there is a need to trap contaminants or simply keep an environment cleaner. They are excellent for…

-

Metro Wire Shelf Finishes: Selection Guide

When should you choose stainless steel over chrome? Learn more about Metro wire shelving finishes including black, Metroseal®, MetroMax, and solid steel shelves.