Dry Cabinet Desiccator Features, Pricing, and Material Construction

Multi-Chamber, Adjustable Shelf Desiccator Dry Cabinets

Acrylic: Economical option for general desiccant applications. Does not support use with aggressive cleaners, heat, or abrasive solvents. Ideal for general purpose processing but can be damaged by alcohol and some cleaning agents.

Static Dissipative PVC: Prevents build-up of electrostatic charges, particles, and dust.

Stainless Steel: Stainless steel is not only a premium construction material but often times required under vacuum pressure. Stainless steel is impervious to most solvents, maintains its surface finish for years to come, and does not support microbial growth for medical device and biopharma items.

Wafer Storage and Wafer Box Desiccators

Desiccator Cabinets for Wafer Storage, 1510 Series

Wafer carrier storage desiccator cabinets provide high-density storage of up to 12” diameter silicon wafers in standard wafer containers/carriers. We can also offer them in pass-through designs for dual-side access. Designed for storage of 200 mm or 300 mm wafers in most standard cassettes and lot boxes. Humidity control system enhances desiccator efficiency and saves up to 70% of nitrogen costs and preserves moisture-sensitive wafers in a dry & particle-free environment.

Nitrogen purge desiccator cabinets options are swappable for desiccant type (nitrogen-free) cabinets upon request. The Desiccator cabinet can be ordered without back plenum in order to have isolated atmosphere chambers.

Amber Acrylic

- Transparent orange-tinted acrylic

- Blocks ultraviolet wavelengths

- Does not hold up to strong cleaning agents and chemicals

Standard Acrylic

- Economical Choice

- Does not hold up to strong cleaning agents and chemicals

- Prone to static charge build-up

ESD Dry Cabinet Features

ESD safe desiccators protect humidity-sensitive samples, products, and electronics in a clean, dry, electro-static safe and oxygen-free environment.

ESD safe desiccators range from singe to ten chamber cabinets with up to 5 stainless steel trays or shelves per chamber. ESD cabinet storage provides a safe and oxygen-free environment for humidity-sensitive samples products and electronics.

Features:

Plenum chamber minimizes backfill ensures uniform gas distribution

Grounded rack, hinge and door latch provide additional ESD safety.

Static Dissipative PVC

- Ideal for storing static sensitive samples

- Prevents build-up of electrostatic charges, particles, and dust

- More chemical resistant compared to non-dissipative materials

Wafer Storage Desiccators

Wafer storage desiccator cabinets or wafer box desiccators have multi-chamber cabinets for 150mm, 200mm or 300mm silicon wafers in an electrostatic safe, humidity controlled, and particle-free environment.

Pass-Through Desiccator System

CleanPro pass-through desiccator cabinets have dual side access for a cleanroom, inventory room wall, or assembly rooms allowing access to stored materials from both sides. The compartments can be fully isolated from each other as each compartment utilizes an inlet and bleeding valve for introduction of nitrogen gas or CDA to complete purging system to reduce the moisture level down to 0%.

Other designs connect compartments through perforations between chamber dividers. A single inlet and bleeding valve connect the entire dry cabinet to an automatic purge control unit. A PCU or purge controller unit provides automatic low-humidity control and monitoring in the range of 5 – 100% RH.

Pass-Thru Desiccators

Pass-through desiccator cabinets store materials accessible from both sides. Usually, a pass-through is connects two rooms separated by a shared wall. The design is common in pharmacies and cleanroom applications. Depending on the application and requirements, compartments connect through a perforated chamber divider or remain isolated for controlled environment applications.

CleanPro®

Stainless Steel

Stainless steel desiccators are designed for storing sensitive samples and products in a dust and moisture-free environment using either a desiccant, nitrogen, or clean dry air.

Related Posts

-

DMS Desiccator Cabinets

You may be asking yourself "What exactly is a desiccator cabinet, and why would I need one?" Desiccators are sealable enclosures containing desiccants used for preserving moisture-sensitive items.

-

Palbam Class N2 Desiccator Cabinets

Palbam Class Stainless Steel Cleanroom Desiccator Cabinets Palbam Class developed its first desiccator cabinets for the Semiconductor Industry. Due to the demands of this industry all the cabinets are manufactured from the cleanest materials possible.…

-

Self-Refreshing Nitrogen-Free Desiccator Cabinets

CleanPro Cabinets are designed and manufactured to be able to maintain an environment of

-

The Hidden Costs of Acrylic Enclosures, Cabinets, and Desiccators

Why Is Static Dissipative PVC a Better Option than Acrylic?

-

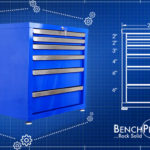

BenchPro Pre-configured Drawer and Tool Cabinets

What makes BenchPro one of the best cabinets available online? BenchPro cabinets, drawers, and accessories are guaranteed for 25 years of use with up to 200 lb. drawers. These pre-configured cabinets allow simple purchasing for…

-

Use These Apps For Designing Commercial Seating & Drawer Cabinets

Design What You Want, Get What You Need The process of online checkout for commercial products demands accommodation for niche fabrication, deep accessory offerings, micro-varied unit sizing, and specialized materials for industry specific use. Design Custom Locking…