How to Avoid Production Fog Amongst Aggressive Supply Chain Goals

Focus on What You Do Best

Trends once indicated that internalized teams provide the most cost-effective solution to supply chain barriers. After decades of success, the internet arrived. Globalization and more accessible markets reduced the burden of market entry and customer acquisition. Small companies began eating away at market shares because they could adapt more quickly, were data savvy, and focused only on what they could do better than everyone else.

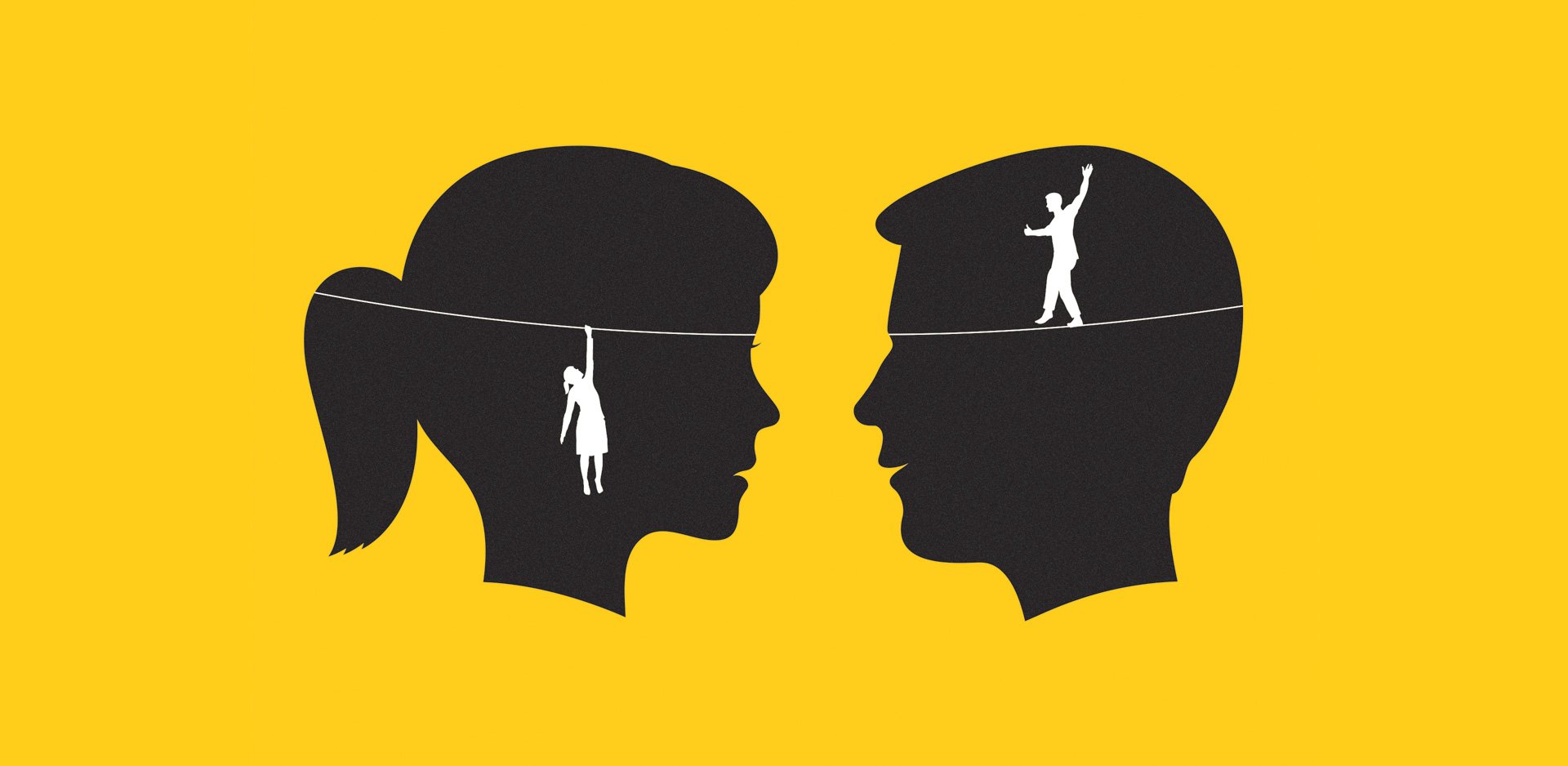

Giant enterprises eventually realized that markets were changing too quickly for large, slow teams. Internal silos and redundant communication chains stifle the ability to make rapid decisions on the road to market. Instead of supporting their strengths like product development, value-added services, and business development, organizations felt that by addressing their core weaknesses that they could build the ultimate competitive advantage.

A sustainable competitive advantage requires doing what you do best. Monolithic enterprises of the 20th century realized that organizing business units under self-managed subsidiaries allowed faster changes amongst new challenges. In areas of least competency, they built key partnerships and segmented product divisions into sovereign and nimble units. This reduced noise in supply and leadership hierarchies. This outpaced manufacturers who stretched internal talents too thin, especially when market conditions were unpredictable:

What Circumstances Cause Hiccups for Over Stressed Supply Chains?

- Worker Shortages & Skill Gaps

- Evolving Policy & Trade Agreements

- Rapidly Changing Consumers Interests

- Environmental & Climate Change Disruption

- Over-Extending Key Players into Less Productive Tasks

Manufacturers take pride in being both flexible and resilient. Faster product development and delivery cycles help meet a customer’s ever-growing need for faster delivery and premium service. This also requires a hurried expansion of warehousing, capital, overhead inventory, and administrative tasks.

How Do We Manage Increasing Complexity of Supply Chains?

Expansion creates unforeseen complexities and challenges within supply chains. Communication breakdowns, competing priorities, and distraction from core competencies interrupt economies of scale. Valuable manufacturing space gets converted into storage space, order minimums become bloated, inventory swells, and eventually, quality and delivery times suffer.

An integrated supply management service avoids costly production fog. Saving time and resources on material management accelerates production and delivery cycles. The reason enterprises choose Production Automation is because we help partners reconfigure their supply chain systems in ways that improve organizational focus, core productivity, and extend competitive advantage.

PAC teams specialize on the finer details so you can stay focused on the big picture. Advanced data and inventory systems are a core of PAC’s ability to impact profitability and increase your connection to customer segments.

- Shorter Lead-Times

- Improved Delivery Performance, Decreased Stock Outs

- Dramatically Decreased Inventory Carrying Costs

- Higher Service Levels & Closer Vendor/Customer Relationships

The PAC network includes an international reach across the Americas, with warehouses and physical locations in Minneapolis, California, Texas, and Mexico. We stock production supplies you need locally for immediate delivery. Many of our sales specialists are factory trained or former process and application engineers. Getting you the right product, at the right time, for the right price doesn’t require nonsense.

PACs supply management services cover include:

Procurement – Help negotiate, procure, and manage vendor relationships, often improving your supplier performance at a lower cost.

Inventory – By shrinking and optimizing your inventory, we’ll lower costs and improve cash flow. This includes managing warranty and return orders.

Supply Chain Data Management – We’ll help you capture the data you’ll need to make strategic decisions regarding your MRO supply chain and structure it so that you can easily extract the information you want.

Connected Web Advertising & Big Data – PAC’s web and marketing operations provide cross-industrial insights across hundreds of brands and thousands of advertising, email, and web search campaigns. Database analytics and reports help you capture the data you need to make strategic decisions. Customer segmentation provides a more informed basis for decisions on pricing, service levels, or unprofitable products. You’ll enjoy identifying aggressive new markets, competing technologies, and staying updated on evolving sales channels.

Over the past 30 years, PAC’s experience has connected the world’s most prominent manufacturers with logistics and supply chain solutions. No PAC solution is one-size-fits-all. We’ve developed a culture of specialists that assess your needs and solve your manufacturing problems. Whether its supply chain execution, planning, or managing customer expectations, solving the right problem starts with asking the right expert.

Related Posts

-

New Product: Bullhead Safety Glasses Now Availble At Production Automation

New: Purchase Bullhead Safety Glasses On The Production Automation Web Store Bullhead Safety™ glasses meet and exceed ANSI/ESD Z87.1-2015 standards with frame styles and lenses for many applications. UV filtration provides 99.9% blockage of all…

-

Just-in-Time Production & Kanban

Introduction to Just in Time Production We've covered 5S Manufacturing processes and Cellular Manufacturing, so today's focus is on another lean thinking method: Just-in-Time Production and Kanban. Just-in-Time Production or JIT, and cellular manufacturing are…

-

The Seven Deadly Sins of Cleanroom Wiping (and How to Avoid Them!)

1. Ignoring the Need to Wipe on a Regular Basis To assure quality is maintained in all cleanroom and restricted areas, housekeeping maintenance must be performed daily. Improper cleaning leads to contamination and ultimately loss…

-

New Product: Bullhead Safety Glasses Now Availble At Production Automation

New: Purchase Bullhead Safety Glasses On The Production Automation Web Store Bullhead Safety™ glasses meet and exceed ANSI/ESD Z87.1-2015 standards with frame styles and lenses for many applications. UV filtration provides 99.9% blockage of all…

-

New Product: Bullhead Safety Glasses Now Availble At Production Automation

New: Purchase Bullhead Safety Glasses On The Production Automation Web Store Bullhead Safety™ glasses meet and exceed ANSI/ESD Z87.1-2015 standards with frame styles and lenses for many applications. UV filtration provides 99.9% blockage of all…

-

New Product: Bullhead Safety Glasses Now Availble At Production Automation

New: Purchase Bullhead Safety Glasses On The Production Automation Web Store Bullhead Safety™ glasses meet and exceed ANSI/ESD Z87.1-2015 standards with frame styles and lenses for many applications. UV filtration provides 99.9% blockage of all…