An Alternative Drying Solution Replaces Traditional Methods

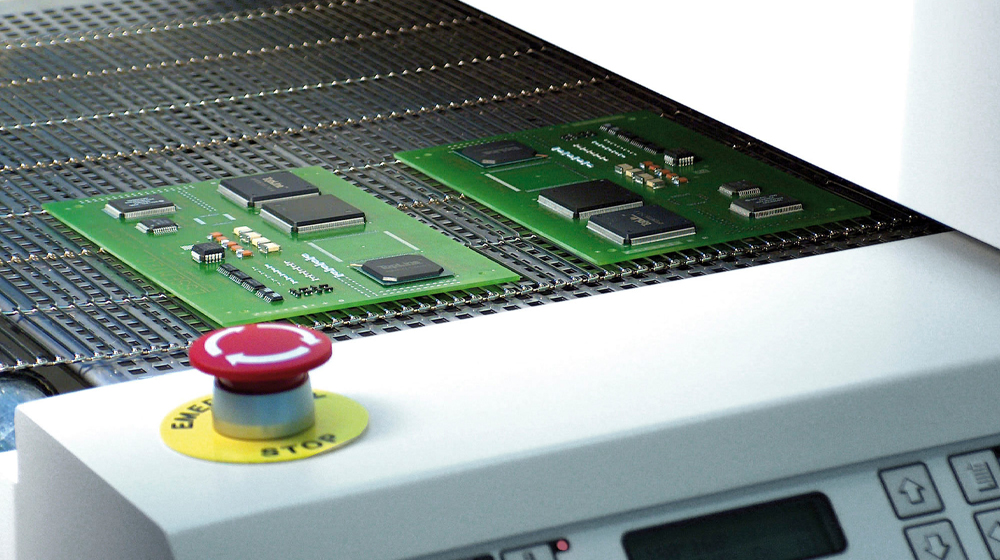

As the industry utilizes a high-temperature reflow process, moisture sensitivity in SMT remains a constant problem. Serious manufacturing defects and failures are much more likely to occur later when products are in the field, which can be traced to improper storage and handling of components and PCBs during the assembly process.

StatPro dry cabinets with desiccant dryer technology employ an alternative drying solution as opposed to traditional methods because field failures will occur without proper moisture control. These are important factors to consider when product reliability must be tightly controlled by manufacturing industries such as automotive, defense, medical device, aeronautic, and aviation.

Why You Need StatPro CPDC Series Desiccator Dry Cabinets

With decreased time in development cycles, invention of ever-smaller devices, innovative use of new materials, and larger wafer chip development, there is a rapid increase of MSDs and higher levels of trace moisture sensitivity during the reflow process. As a result, internal component damage due to trace moisture expansion will occur in MSDs.

By storing MSDs and other valuable components in StatPro dry cabinets, you will be ensured of extended floor life. This will also prevent moisture expansion, popcorning, intermetallic growth, oxidation, solderability, and other moisture-related problems from occurring.

How Trace Moisture Affects SMT Production

Trace moisture causes component and PCB failure during the high-temperature reflow process. When absorbed moisture rapidly expands from high temperatures, internal component damage and failure such as micro-cracking, blistering, and popcorning will occur in MSDs, packages, and components. Because PCBs are hygroscopic, absorbed moisture will lead to delamination when moisture inside the layers expands during the process.

StatPro CPDC Series Desiccator Dry Cabinets Applications

When components are removed from moisture barrier bags, StatPro’s ultra-low humidity dry cabinets will stop the floor-life clock for all IC packages:

- Dual-in-line – Flatpack, SOIC, SOJ, TSOP, SSOP, TSSOP, QSOP, VSOP, and DFN

- Quad-in-line – PLCC, QFP, LQFP, PQFP, CQFP, MQFP, TQFP, QFN, LCC, MLP, and PQFN

- Grid arrays – PGA, BGA, LGA, FBGA, LFBGA, TFBGA, CGA, CCGA, µBGA, and LLP.

Other applications:

- Drying and storage of multi-layer PCBs and PWBs before and after mounting, including dual-side boards awaiting second-side reflow

- Moisture controlled storage with desiccating capabilities for PCB pattern film/prepreg, quartz, fiber optics, CCDs, etc.

- PP plate, prepreg, solder paste, semi-mounted PCB, mounted PCB, die cast and mold compounds, bonding materials, fluorescence powder, LCG board, wafer, CCD, condenser, oscillators, etc.

Related Posts

-

DMS Desiccator Cabinets

You may be asking yourself "What exactly is a desiccator cabinet, and why would I need one?" Desiccators are sealable enclosures containing desiccants used for preserving moisture-sensitive items.

-

Solve Your Moisture Problems with a StatPro CPDC Series Dry Cabinet

StatPro CPDC Series Desiccator Dry Cabinets are widely used and trusted by professionals in the high-tech, R&D, electronic manufacturing, laboratory, cleanroom, and warehouse industries. These utilize self-regenerating desiccant dehumidifiers to provide an ultra-low humidity environment. With…

-

Filament Storage Cabinets for 3D Printing

Notably, filaments such as nylon may absorb unacceptable amounts of water in the short period of time they are on the printer. This cabinet provides active feedports for use during prints, and long term storage…

-

Filament Storage, Dry Boxes and Spool Cabinets for 3D Printing

Are you ruining your 3D printing filaments by baking them? What's the best way to dry FDM and PLA filaments? What about Nylon and PLA?

-

Palbam Class N2 Desiccator Cabinets

Palbam Class Stainless Steel Cleanroom Desiccator Cabinets Palbam Class developed its first desiccator cabinets for the Semiconductor Industry. Due to the demands of this industry all the cabinets are manufactured from the cleanest materials possible.…

- How to Use Desiccants with Moisture Vapor Barrier Bags

What is Desiccant? Desiccant is a drying agent that is used to absorb moisture from the air inside moisture barrier bags. Desiccant absorbs moisture vapor (humidity) from the air left inside the barrier bag after…