Radioactive Static Eliminators – Alpha Ionizers

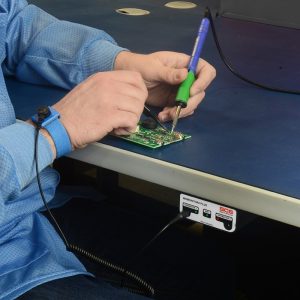

An alpha ionizer produces alpha particles which eliminate static electricity during sensitive manufacturing or electronics fabrication processes.

The radioactive source (Po-210) in the Alpha Ionizer is encapsulated inside a solid metallic foil or electroplated onto a backing foil and inserted into a brush, tube, or another holder. Separating the polonium from the electroplated material is Electroplating makes separating the polonium from the device nearly impossible. the It has been shown that there is no chance of ingesting particles from such encapsulated ionizing sources.

Therefore, an Alpha Ionizer such as those from NRD create no hazard from alpha radiation under normal mounting and operating conditions. The sealed source material is permanently bonded to prevent the release of the material even under the most severe conditions of normal use and handling.

Ionization equipment balances positive and negative ions during the production of sensitive electronics equipment. There are a number of different ionization equipment styles including benchmount fans, top mount blowers, guns, and bars for assembly conveyors

Radiation In NRD Alpha Ionizers

NRD ionizers use a low-level alpha particle radiation source with a short-range in the air usually between 3cm – 25cm. Short ranging makes them safe to use by personnel while still providing high ion output.

Airborne alpha particles travel only a few inches at most and have little penetrating power. Alpha particles are not considered an external radiation hazard because the dead layer of skin easily stops them. The only way alphas can be harmful is by ingestion or inhalation of an alpha emitter (internal exposure). Internally, the source of alpha radiation can be in close contact with unprotected body tissue and can deposit a large amount of energy in a small volume of body tissue.

Is an Alpha Ionizer Hazardous? What is the Risk?

What is Polonium-210?

Polonium-210 (Po-210) is a product of the radioactive decay of natural uranium

(U-238) found in the earth’s crust. Polonium decays to a stable form of lead (Pb-206) by emitting alpha particles. A very small percentage of the time (0.0012%), 803 keV gamma rays are also generated in this decay.

The small amount of 803 keV gamma radiation produced in the decay process is further attenuated with the metallic foil structure and the steel frame of the ionizer.

Are Polonium Ionizers Safe?

Polonium emits alpha particles, not to be confused with more destructive gamma particles capable of penetrating through walls and skin. Alpha particles cannot penetrate the skin and rapidly decay over short life cycles. Alpha particles are not able to traverse airborne distances, usually with a maximum travel distance of 3 – 10 cm.

Most alpha particles will use up their energy while traveling through a single sheet of ordinary notebook paper. The primary health concern associated with alpha particles is that when alpha-emitting materials are ingested or inhaled, energy from the alpha particles is deposited in internal tissues such as the lungs.

However, Polonium-210 poses no hazard to workers or materials unless ingested directly. Po-210 is not a hazard to the outside of the body—neither polonium nor its radiation will go through unbroken skin or membranes. Careful washing will remove most external traces of Po-210.

“Po-210 is a radiation hazard only under extraordinary circumstances, such as in the case of a direct absorption into the body through breathing or eating or by entering a wound. If large quantities are inhaled or consumed in a fairly short period of time, this “internal contamination” can cause radiation exposure of internal organs, which can result in serious medical symptoms or death.” – CDC

Polonium Radiation Exposure and Health Risks

Radiation health risk assessments require understanding the nature of radiation. The body’s response to radiation varies upon the type, energy, and exposure radius. Unlike electromagnetic radiation (gamma rays), alpha and beta rays cannot pass through the body, skin, or tissues. Let’s consider that paper is a suitable barrier against alpha rays, whereas radiation protection from gamma radiation requires an extremely dense material such as lead, steel, zinc, or concrete.

Under normal mounting conditions, the Ionizer is about two (2) feet away from the workspace. If a person were to work 8 hours a day for a whole year, the annual occupational dose would still be less than 2 mrem. Such a low amount of exposure is hard to measure against background radiation.

The exposure from a single dental X-ray is at least 100 times higher than the radiation dose from the Alpha Ionizer in a year.

Polonium Regulation – Nuclear Regulatory Commission Requirements

OSHA (29 CFR 1910.1096) covers the use of ionizing radiation in the general industry. These are based on the US Nuclear Regulatory Commission regulations covering the use of radioactive material. Section 29 CFR 1910.1096 (p) specifies that an employer who uses radioactive material under the terms of a valid NRC or Agreement State license “shall be deemed to be in compliance with the requirements of this section with respect to such possession and use.”

Hazard Communication / Material Safety Data Sheet (MSDS) Exclusion

Ionizing devices manufactured by NRD, LLC are excluded from the OSHA Hazard Communication and Material Safety Data Sheet requirements. This exclusion is stated under 29 CFR 1910.1200 (b) (6) (xi).

The occupational dose limit for a radiation worker in the United States of America is 5000 mrem per year. To have a better perspective, it should be noted that the average background radiation from natural sources is about 300 mrem/yr. (~ 35 micro rem*/hr.).

Typical exposure levels from typical scenarios in the U.S include:

Chest X-ray: 20 mrem

Dental X-ray: 200-700 mrem

Cross-country jet flight: 5-10 mrem

Smoking cigarettes: (1.5 packs/day) 8,000 mrem/yr

Pacemaker: 700 mrem/yr

Radiation Protection

The exposure from any type of radiation can be limited by controlling the following factors: Time, Distance, and Shielding.

Time: The greater the time one is exposed to the radiation source, the greater the exposure (dose).

Distance: Doubling the distance from radiation source reduces the exposure four times.

Shielding: Any material placed in between the source of radiation and the occupied area will absorb some of the radiation and thus reduce the exposure. The more material used, and greater its density, the more radiation will be reduced.

Knowledge of the type, energy, and exposure rate is required in order to determine the effect of radiation on the body. For example, alpha particles of the same energy and exposure do not have the same effect on the body as gamma rays. Alpha particles cannot penetrate even the outer layer of skin, but gamma rays penetrate human tissue and shielding.

High-energy gammas are more penetrating than low energy. Exposure can be external or internal. External exposure is from any radioactive source external to the body. Internal exposure is the exposure caused by ingested or inhaled radioisotopes.

The greater the exposure greater is the risk of biological effects. High levels of exposure to ionizing radiation will damage or kill the cells which make up our bodies. Cancer can result from cells that are damaged but survive.

Get Help from a Static Control Specialist

No facility is one-in-the-same. Demand continually grows for a greater degree of product choices with in-stock availability. How can we help?

Production Automation (PAC) is recognized as an ESD specialized organization by enterprises across the US and Latin America. That’s because we directly support each of our ESD product lines from its original invoice to final delivery, including on-site satisfaction, returns, and warranties.

We provide authentic, manufacturer direct static control equipment for general and critical environments including garments, packaging, workstations, flooring, furniture, and test devices.

Ask our static control experts for help with product selection for ANSI/ESD & ESDA standards.

Related Posts

-

Frequently Asked Questions about Alpha Ionization: Operation, Cleaning, Repair, and More

PAC is an authorized distributor of NRD Static Control and Ionization products. We've reposted this information from the NRD knowledge-base to better serve our customers. NRD Alpha ionizer vs AC ionizer - What's best for…

-

What Are the Differences Between Corona and Alpha Ionization?

This post covers the different types of static control ionization equipment and technologies. Which is best for your application?

-

Air Ionization: How it works

What is Air Ionization and How Does it Work? Air ionization neutralizes static charge on insulated and isolated objects by producing a balanced source of positively and negatively charged ions. Whatever static charge is present…

-

Cleanroom Ionizer Selection Guide

What is the advantage of ionizers for static control and particle cling? How do I select the right ionizer? View the selection guide.

-

ANSI/ESD Standards: Design, Training, and Safety for Organizations

Today, more than ever, meeting the complex challenge of reducing ESD losses requires more than reliance on faith alone. Users require a way to legitimately evaluate and compare competing brands and types of products. They…

-

Air Ionization for Particulate & Contamination Control PDF from Simco-Ion

Our friends at Simco-Ion sent us this brilliant guide to ESD cleanrooms design, principles, and other considerations. Download the PDF you’ll find case studies and technical information about how static charges influence particle retention and…

-

ESDS Device Sensitivity and Testing: The Fundamentals of Electrostatic Discharge, Part 5

This copyrighted information is licensed for reproduction by EOS/ESD Association, Inc. Click here to view the original article. In Part Two of this series ("Principles of ESD Control – ESD Control Program Development"), we indicated that a…

-

Self-Install ESD Flooring Kits

Over time, an ESD floor will incur wear and eventually require replacement. A contractor will likely recommend that the entire floor is replaced. But is there a better way?

-

Air Ionization: How it works

What is Air Ionization and How Does it Work? Air ionization neutralizes static charge on insulated and isolated objects by producing a balanced source of positively and negatively charged ions. Whatever static charge is present…