StatPro CPDC Series Desiccator Dry Cabinets are widely used and trusted by professionals in the high-tech, R&D, electronic manufacturing, laboratory, cleanroom, and warehouse industries. These utilize self-regenerating desiccant dehumidifiers to provide an ultra-low humidity environment. With no N2/dry-air purging, these provide automatic control of <5% RH with very fast recovery times at NTP conditions. Because these rely on the moisture absorbing properties inherent in the desiccant material, they require no calibration. Moreover, these cabinets increase product quality, reliability, and yield rates.

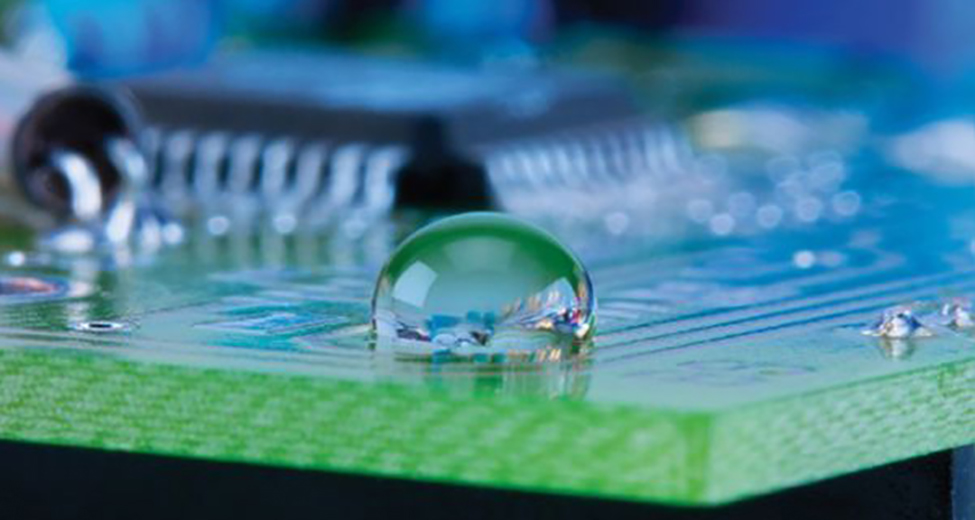

These dry cabinets fix moisture problems with ultra-low humidity storage that adheres to industry standards for MSDs and PCBs. These cabinets dehumidify during storage and provide an alternative drying method that is optimal for removing moisture in SMT production, which eliminates damage during the reflow process. Nitrogen only displaces water vapor in the air and cannot aid in removing moisture already absorbed by sensitive devices.

StatPro dry cabinets avoid thermal and moisture re-trapping effects, which protects against breakdowns of protective coatings, lead oxidation, and intermetallic buildup while reducing solderability of circuit boards. Moisture is expelled from the cabinets with desiccant dehumidifiers that automatically regenerate. No fans are required to ventilate, and dual-hydrometer sensors with independent monitoring allow for gauging RH levels inside the cabinets.

The 6-door cabinet center stiles are removable to accommodate long tubes, feeders, or trays up to 43″ in length. All cabinets are painted with anti-static paint and include anti-static glass windows, shelves, stands with casters, and a ground wire with 1MO for your storage protection meeting IEC-61340-5-1 (ESD) standards. These cabinets require no calibration and use the fewest moving parts, which means less can go wrong – all while using the least possible amount of energy.

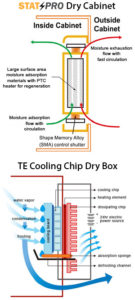

Shape Memory Alloy Technology vs. TE Cooling Chip Technology:

StatPro CPDC Series Desiccator Dry Cabinets contain exclusive and innovative adsorption technology – desiccant dryers with Shape Memory Alloy control valves. This technology distinguishes StatPro’s performance from those using TE Cooling Chip technology. The multi-porous molecular sieves trap moisture by way of van der Waals forces using multiple capillary channels, while SMA control valves expel moisture from the cabinets and prevent moisture from reemerging if power is interrupted.

When power is supplied to cabinets using TE Cooling Chip technology, the external side of the unit warms while the inside cools. As a result, moisture condenses on the inside where your valuables are stored. The condensed moisture naturally drips down toward the warm side of the core where it is then vaporized.

Dehumidification

Desiccant dryer technology is not affected by ambient temperatures, so even low temperatures are not an issue for StatPro dry cabinets. The SMA technology utilized by the cabinets also features a dehumidification capability of <5% RH with a recovery time of

TE Cooling Chip technology is adversely affected in lower temperatures. The result is a reduced desiccation rate and a less stable dehumidification process. Dehumidification levels that are below 20% RH are not only unattainable with TE Cooling Chip technology, but they are also unreliable.

Power Outage Protection

In the event of a power outage, the Shape Memory Alloy unit’s outer valves automatically shut and remain closed to prevent moisture from entering the box. Meanwhile, the inner valves remain open and allow continuous adsorption via the multi-porous molecular sieves.

TE Cooling Chip technology is not capable of keeping out moisture. The dehumidification process stops, which allows frost to collect on the inside. The frost melts and allows moisture to circulate back into the cabinet. Also, the valves may remain open and allow outside moisture to enter, depending on the desiccating cycle.

Easy Repair Services

In the rare event a core unit or hygrometer malfunctions, the StatPro cabinets allow you to simply remove the SMA unit from the cabinet for easy in-house replacement. Based on user needs, these core units and hygrometers are also user upgradable, which is in keeping with StatPro’s concept of long-term use and environmental friendliness.

TE Cooling Chip technology cabinets can be costly and time consuming to repair. When a TE Cooling Chip unit malfunctions, the entire unit must be shipped back to the manufacturer to be repaired, which adversely affects protection from humidity in addition to accumulating costs.

Silent, Reliable Operation

StatPro dry cabinets with desiccant dryer technology are fully automatic with silent operation cycles, while the TE Cooling Chip cabinets utilize noisy fans and transformers that can malfunction easily.

The low power consumption, no calibration, and plug and play operation make StatPro CPDC Series Desiccator Dry Cabinets a viable option for long-term storage of all production components. Using StatPro results in the ultimate production goal – higher yields.

Related Posts

-

Arlink 7000 & 8000 Series Workbenches

The Arlink 8000 series workstation offers the industry's fastest and simplest set-up and reconfiguration. Virtually no hardware or tools are required, making changes efficient and frustration-free. With an emphasis on ergonomics, the Arlink 8000 series…

-

Dry Box Desiccant Storage within the PCB Manufacturing Environment: Uses, History, Selection, and Performance

Manufacturing Uses of Desiccator Cabinets for Printed Circuit Boards (PCBs) The discussion regarding 'dry box' or desiccant storage of MSD's (Moisture Sensitive Devices) has increased over the past years with the introduction of new IPC…

- How to Use Desiccants with Moisture Vapor Barrier Bags

What is Desiccant? Desiccant is a drying agent that is used to absorb moisture from the air inside moisture barrier bags. Desiccant absorbs moisture vapor (humidity) from the air left inside the barrier bag after…

-

Weller WX Series Soldering Stations

The name Weller has long stood for innovative solutions in soldering. Now, Weller has achieved yet another milestone with the new WX Series control units. The WX Series is an innovation that Weller owes in…

-

How Dry Cabinets Solve Moisture Problems During SMT Reflow

An Alternative Drying Solution Replaces Traditional Methods As the industry utilizes a high-temperature reflow process, moisture sensitivity in SMT remains a constant problem. Serious manufacturing defects and failures are much more likely to occur later…

-

How Dry Cabinets Solve Moisture Problems During SMT Reflow

An Alternative Drying Solution Replaces Traditional Methods As the industry utilizes a high-temperature reflow process, moisture sensitivity in SMT remains a constant problem. Serious manufacturing defects and failures are much more likely to occur later…