Because flat panel display (FPD) manufacturing is performed in a cleanroom environment, it faces the same problems resulting from static electricity buildup that other high technology manufacturing processes in cleanrooms do. Static charge developed throughout in manufacturing process causes dramatic increases in product contamination. Even worse, discharge on panel surfaces can result in damage to the delicate thin film transistors (TFT) and color filter structures, rendering the panel useless.

To combat static charge, FPD fabs employ air ionization to dissipate the surface charge on panels and the surrounding environment. This technique increases the electrical conductivity of the air and provides a path to ground for the surface charge. The most commonly used ion delivery modes in FPD ionization are bi-polar and pulsed DC. Both technologies are employed to minimize recombination of the two ion polarities. Due to the dynamics of ion travel in these delivery modes, discussed below, it is necessary to employ synchronization technology to achieve fill electrostatic discharge control.

Ion Movement Considerations

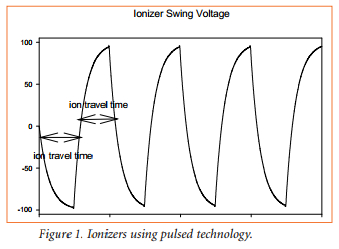

Bi-polar mode functions by successively emitting positive ions then negative ions from each emitter point. Pulsed DC is similar by employs separate emitter points for each polarity. By alternating and generating each ion polarity for the duration of the ion travel from the emitter to the product, recombination is drastically reduced and delivery efficiency is maximized. (The swing is roughly sinusoidal, so sine waves are used for simplicity in the figures below.) See Figure 1.

Ions move in laminar air flow but can be driven more strongly by electric fields. THe resulting fields from the voltage required to operate corona ionizers are an important consideration when operating two or more ionizers in close proximity (≤1 m) to each other. If two ionizers near each other are out of phase (one with positive output and the other with negative output, both on simultaneously), the ions from each ionizer will travel toward the other ionizer rather than downward in the laminar air flow as they should.

When this happens, the ions from each ionizer recombine, resulting in no static protection at the target. Unless there is some way to make the two ionizers work together in phase, there is no guarantee that the ionizers will protect the product.

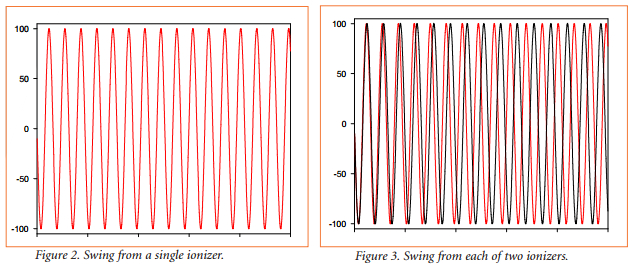

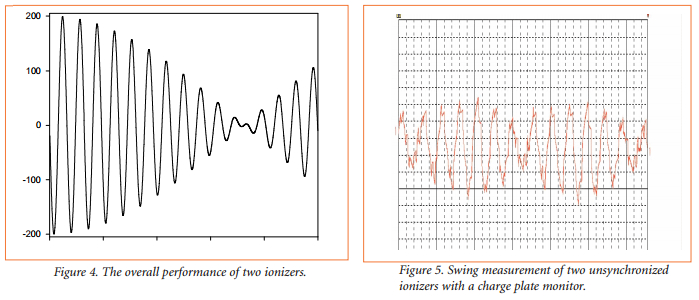

As Figures 2 and 3 show, the waveforms from two ionizers continuously progress from in phase to out of phase and back again. Consequently, the sum of the waveforms first exhibit constructive addition of the two ionizers, but are then cancelled out due to recombination, providing no discharge protection. Figure 4 shows the sum of the two waveforms.

Synchronization for Efficiency

The net effect of two asynchronous ionizers is that excellent protection is provided part of the time, with no protection provided the rest of the time. As a result, the ionizers do not provide continuous protection of the products. A charge plate monitor (CPM) was placed under a pair of ionizers operating asynchronously. The resulting trace shown in Figure 5 clearly shows the same pattern as was predicted in Figure 4.

The solution to this dilemma is to ensure that the ionizers are synchronized with each other, This is accomplished by issuing a synchronization pulse to all ionizers within a single control system so that they are brought into phase with each other. If the ionizers have a synchronization feature, the performance of the two ionizers together is assured all of the time rather than part of the time. If this is the case, the amount of yield loss due to electrostatic discharge will be lower than if the ionizers are not synchronized.

Why Do We Recommend Simco Ion Solutions?

There are a number of solutions that ensure synchronization features. Every application has specific static control or particle contamination control requirements. We recommend Simco-ION because they provide static control and ionization solutions for various manufacturing processes and environments aimed at increasing productivity and quality. This allows us to meet both the highest standards of quality for our customers across many industries with quality and consistency. That way, we can help you identify problems areas in your work space and guide you through the process of selecting the right equipment to solve those problems within your budget.

Aerostat® FPD 4-Fan Ionizing Blower

The Aerostat FPD series of products has been designed to control electrostatic charges in assembly and electronics manufacturing applications requiring stable operation with exceptionally fast discharge time performance. The FPD overhead products are built for reliability and simplicity.

Related Posts

-

Is Linoleum Flooring Conductive or Anti-Static?

Genuine linoleum is a 100% biodegradable material composed of linseed oil, pine resin, cork, wood, pigment, and limestone. Depending on material construction, it is known to have antistatic properties which mitigate some triboelectric charges that…

-

Static Control Flooring, ESD Epoxy, and Anti Static Primer. How It's Used and Where to Buy It

Static Free Flooring, ESD Tile, and ESD Coatings Updated 9/27/17 As static-sensitive electronic components grow more intricate, so do consumers of static-control flooring. Here are some key points to consider when choosing flooring for home…

-

What Is Conductive Flooring? How Is It Different from Anti-Static?

Definition of Conductive Flooring ANSI/ESD S20.20 flooring specifications, see here. Moving feet and contact with objects generate triboelectric charges. Static sensitive areas require a grounded flooring surface which is slightly conductive but not overtly. ANSI Defines…

-

ISO 7 Cleanroom Panel Cleaning & Maintenance

Warm water and a mild dish soap is the best softwall curtain cleaning solution. What about acrylic, melamine, and aluminum? Generally, any biodegradable solution is acceptable. A 50/50 solution of Isopropyl Alcohol & DI water…

-

2019 Cleanroom Trends: Static Control, Process Monitoring, and Quality Control

Trends in the cleanroom market: reducing production costs, improving environmental conditions, and extending customer support with expertise.

-

What's the Difference Between Anti-Static and Static Shielding Bags?

Standard pink anti-static bags fail to protect ESD-sensitive devices from the flow of electrically charged objects. Learn about the requirements for ESD safe packaging, metal faraday bags, and the differences between anti-static, dissipative, and conductive…