Legend Quick Ship Series Hardwall Cleanrooms

Ships within 5 business days of receiving order!

Pre-engineered, modular design cleanrooms are cost effective without the inconvenience of conventional “stick-built” construction.

Once Through Design

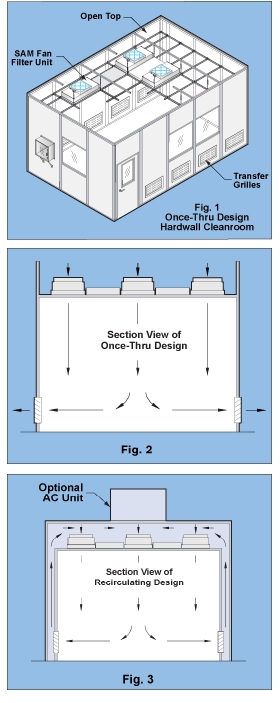

Once-Thru Design is also known as single pass. Ambient air is drawn into the SAM Fan Filter Units at ceiling level. The filtered air passes into the cleanrooms and is transferred out of the room through grilles at the bottom of the walls.

Quick Ship Series Specifications

Cleanroom Wall Material: White wall panels mounted into 2″ clear anodized aluminum framing.

T-Grid Ceiling System: 2″ HD T-Bar with anodized aluminum finish. Includes all connectors, suspension hardware and gasket to be applied on site.

Ceiling Support Structure: Suspension support beams attached to top of cleanroom walls for suspending T-Grid Ceiling System. No support required from host building.

Windows: (1) Nominal 46″W x 39″H tempered glass, double glazed, flush mounted in anodized aluminum frame.

Entry Door: (1) 3′ x 6′ 8″ Door with viewing window, passage lever and spring hinges.

Return Air/Transfer Grilles: Properly Sized for airflow relief.

Interior Height: Eight feet, overall height is ten feet.

Lighting: 4-Lamp cleanroom light fixtures with energy efficient T8 electronic ballasts. Fluorescent lamp tubes are not included.

Ceiling Panels: Cleanguard ceiling panels with sealed edges for spaces not occupied by SAM Fan Filter Units or light fixtures.

HEPA Filters: SAM 2′ x 4′ Fan Filter Units, 115V with 99.99% HEPA Filter, variable speed control and all other standard specifications as manufactured by Clean Rooms International.

Electrical: Electrical connections to the building power source are to be completed on site by a qualified electrician at buyer’s cost.

Electrical: Electrical connections to the building power source are to be completed on site by a qualified electrician at buyer’s cost.

Assembly: Legend Cleanrooms are knocked down for shipment. Detailed assembly instructions are included with shipment.

Submittal Drawings: A prepared submittal drawing will be sent with Order Acknowledgment after a purchase order is received. To qualify for a 5 business day lead time, options, modifications, or revisions will not be possible.

Options: If options, modifications or revisions are required, additional lead time will be necessary. Contact Production Automation for information on effects on lead time and pricing.

Legend Cleanroom Designs

Provides Controlled Environment: Legend Hardwall cleanroom Wall Panels and Components are engineered to provide a secure controlled environment within the cleanroom.

Non-Progressive Design: As needs change, Legend wall panel modular design offers the ability to relocate or expand the cleanroom in the future.

Special Sizes: Wall panels can be made in special sizes for entry areas, gowning rooms and air-locks, ensuring that the cleanroom pressure remains constant. Extra-high, legend wall panel systems can accommodate large equipment which can require ceilings higher than the standard eight feet.

Load Considerations: Three factors are considered when determining which wall system to use for load-bearing cleanrooms. The first factor is the amount of total weight on the cleanroom wall, the second factor is the span distance between all four of the cleanroom walls and the third factor is the height of your wall. Consult with Production Automation for detailed information about your cleanroom project.

Once Through Design: Ambient air is drawn into the SAM Fan Filter Unit at ceiling level. The filtered air passes into the cleanroom and is transferred out of the room through grilles at the bottom of the walls. Refer to figures 1 and 2.

Recirculating Design: Recirculating cleanrooms are ideal when temperature or humidity control is required. Refer to figure 3.

Legend Cleanroom Classes

How are Cleanroom Standards Determined?

The number and size of particles allowed in the room determines the classification of air cleanliness.

Guidelines for selecting filters: PAC can help make the calculations necessary to achieve the desired ISO or U.S. Federal Standard 209 Class. The correct quantity of HEPA or ULPA grade filters will be selected using air changes per hour as the most effective method for meeting class requirements.

Installation, Testing and Certification: A network of authorized installers enables Cleanrooms International to offer complete installation services or testing and certification, which Production Automation can help arrange if needed.

Accelerated Depreciation: Conventional construction becomes a permanent part of the host building and requires the straight-line method of depreciation over as long as 39 years, depending upon current law. A shorter depreciation life for the modular cleanroom results in a quicker write-off and faster payback for the cost of the room.

Modular cleanrooms built from Legend Cleanroom Systems can qualify for accelerated depreciation vs. conventional construction. Consult with your accountant to determine if favorable depreciation rules apply to your purchase of a Legend Cleanroom System.

Guidelines for Cleanroom Classifications

Airborne Contaminate Sizes

View all Legend Quick Cleanroom options at Production Automation

Questions: 888-903-0333

Related Articles

- Air Quality Requirements During the Food Process (brighthub.com)

Related Posts

-

CleanPro® Stand Alone Hardwall Cleanroom

CleanPro’s modular hardwall cleanroom solutions adapt alongside changing floor and production layouts.

-

CleanPro® Softwall Cleanroom Curtains Installation

Softwall cleanroom curtains, sometimes referred simply as “plastic strips” yield ISO Class 10,000 level particle control with minimal construction. This customer required a custom softwall installation that integrated into their existing building structure CleanPro to…

-

Everything You Need to Know About Building A Cleanroom: ISO Class Prefab Hardwall Cleanroom Design

Advantages for Modular Hardwall Design and Construction of ISO 14644-4 Cleanrooms.

-

USP <800> Compounding Cleanrooms

Updated: USP 800 is a cleanroom standard issued in March of 2014 by the United States Pharmacopeial Convention (USP). The deadline December 2019 for compliance may change.

-

CleanPro® Softwall Cleanroom Enclosure

This customer needed to enclose a piece of machinery, and CleanPro® was able to provide a solution.

-

CleanPro® Stand Alone Hardwall Cleanroom

CleanPro’s modular hardwall cleanroom solutions adapt alongside changing floor and production layouts.