What Are the Differences Between Corona and Alpha Ionization?

This post covers the different types of static control ionization equipment and technologies. Which is best for your application?

This post covers the different types of static control ionization equipment and technologies. Which is best for your application?

PAC is an authorized distributor of NRD Static Control and Ionization products. We’ve reposted this information from the NRD knowledge-base to better serve our customers.

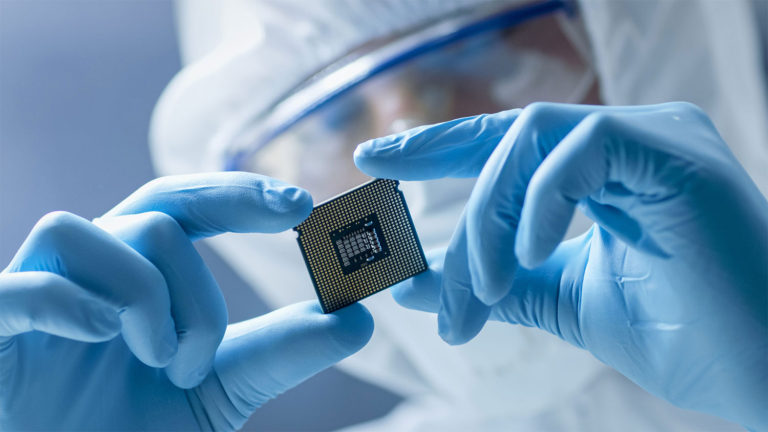

Our friends at Simco-Ion sent us this brilliant guide to ESD cleanrooms design, principles, and other considerations. Download the PDF you’ll find case studies and technical information about how static charges influence particle retention and impact manufacturing outcomes in controlled environments. Below we’ve highlighted important ideas in relation to medical device cleanrooms and provide additional resources.

Genuine linoleum is a 100% biodegradable material composed of linseed oil, pine resin, cork, wood, pigment, and limestone. Depending on material construction, it is known to have antistatic properties which mitigate some triboelectric charges that cause zaps and static buildup.

Lista’s intense focus on detail has lead to levels of design, aesthetic and manufacturing excellence that are unmatched by any other storage or workspace solution provider. We’ve compiled some of the best-in-the-industry features for electronics manufacturing below:

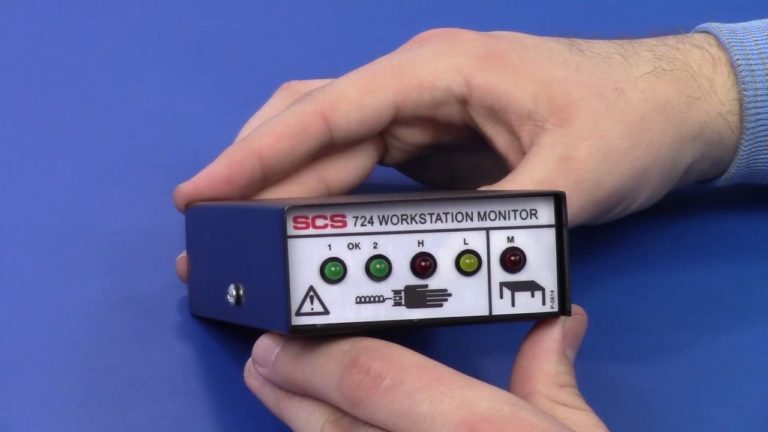

Reposted from Our Vendor SCS-Static-Control Solutions Dual wire ESD monitors and ESD wrist straps are the most common personnel grounding device to ground operators. In today’s

Standard pink anti-static bags fail to protect ESD-sensitive devices from the flow of electrically charged objects. Learn about the requirements for ESD safe packaging, metal faraday bags, and the differences between anti-static, dissipative, and conductive packaging.

Definition of Conductive Flooring ANSI/ESD S20.20 flooring specifications, see here. Moving feet and contact with objects generate triboelectric charges. Static sensitive areas require a grounded

Why Is Static Dissipative PVC a Better Option than Acrylic?

When working on ESD-sensitive projects, whether at home, in a repair shop, or even a large-scale manufacturing operation, having you and your work area fully grounded is a necessity.

Personal Protective Equipment, or PPE, is designed to protect workers from serious workplace injuries or illnesses resulting from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards.

What is Air Ionization and How Does it Work? Air ionization neutralizes static charge on insulated and isolated objects by producing a balanced source of

All personnel in an organization who handle ESD sensitive items (ESDS) are to receive ESD control training. In addition, facilities personnel and those who design

Today, more than ever, meeting the complex challenge of reducing ESD losses requires more than reliance on faith alone. Users require a way to legitimately evaluate and compare competing brands and types of products. They need objective confirmation that their ESD control program provides effective solutions to their unique ESD problems.

This copyrighted information is licensed for reproduction by EOS/ESD Association, Inc. Click here to view the original article. In Part Two of this series (“Principles of ESD

This copyrighted information is licensed for reproduction by EOS/ESD Association, Inc. Click here to view the original article. Your static control program is up and running. How

How do I identify problem areas for ESDS items? Which areas of our facility need ESD protection? This guide identifies the procedures and materials in EPA and ESD environments.

This copyrighted information is licensed for reproduction by EOS/ESD Association, Inc. Click here to view the original article. ESD Control Program Development In Part One of this

This copyrighted information is licensed for reproduction by EOS/ESD Association, Inc. Click here to view the original article. History & Background Greek scientist, Thales of Miletus mentioned