Table of Contents

When Should I Replace a Cleanroom Fan Filter?

Pre-Filter Replacement

HEPA & ULPA Filter Replacement

Optimal Fan Filter Efficiency and Cost Savings

Yes, extending the operating life of a filter reduces overhead and maintenance costs. Longer filter life cycles increase energy use as the filter clogs with particulate. The energy penalty to move air through a dirty filter often outweighs the cost of replacement.

Operating a filter to its most extreme boundaries rarely has an economic advantage. Maximize performance and filtration investment by replacing dirty fan filters once the pressure drop has doubled from the initial installation value.

Fan Filter Servicing

Reducing Air Handling Noise & Cleanroom Footprint

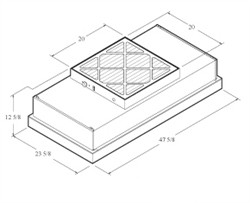

MicroSound Fan Filter Units include a 99.99% efficient HEPA filter, 30% ASHRAE pleated type prefilter, seismic clip suspension points, and a safety switch which disables the unit while servicing. A solid state variable speed control with RFI suppression allows fine-tuned airflow.

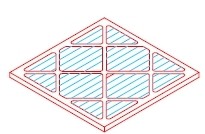

Housings are fabricated from steel with a white powder coat finish. Final filters are protected with a white epoxy diamond pattern grille and are tested according to accepted procedures as described by the Institute of Environmental Sciences (IEST) and/or ISO standards.

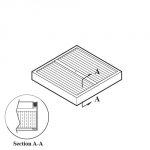

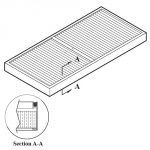

Critical applications may require 99.99% efficient HEPA or 99.9995% efficient ULPA filters. An anodized aluminum frame holds the media which is protected by a diamond pattern white epoxy coated steel grille. Once the unit is removed from the housing removing and reinstalling the filter is , placing on a bench, removing and replacing the filter and re-installing the unit in the ceiling.

Need Info on a Specific Cleanroom Filter?

Related Posts

-

Cleanroom Fan Filter Testing and Maintenance - HEPA Filter Replacement and Troubleshooting

How do I know when to replace my cleanroom HEPA air filters? How do I test a cleanroom HEPA filter? What are the best practices for cleanroom HEPA filter replacement?

-

How do I Calculate ISO 5 Cleanroom Air Change Rates (Class 100)

What is the proper way to calculate ISO 5 cleanroom air change rates? View ISO air velocity requirements and cleanroom benchmarks. (Class 100)

-

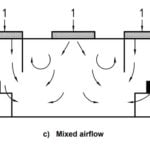

The Truth about Cleanroom Air Change Rates, Charts & Methods of Calculation

Why Can't Anyone Agree on Benchmarks for Cleanroom Air Change Rates? There are a number of best practice guides and benchmarks for cleanroom air change rates (ACR). Many of which reference charts dating back as…

-

Medical Device Cleanroom Construction Part 3: Fan Filter Units - Ceiling Grids

In this post, we overview technical considerations for clean room fan filter unit selection, installation, and features. You'll learn how PAC approaches design and configuration of cleanroom HEPA filter units and fan filter housing specifications.…

-

Medical Device Cleanroom Construction Part 5: HVAC Balancing & Calibration

Before cleanroom validation, a cleanroom requires mechanical calibration. HVAC calibration first ensures that the room meets the performance parameters which would deliver the expected results during final ISO validation, such as differential pressure, air change…

-

Cleanroom Fan Filter Units vs Air Handling Units

A cleanroom air handling unit (AHU) is a cornerstone of temperature, humidity, and pressurization within controlled environments. Today, modular fan filter units allow more adaptable configuration with simplified maintenance procedure. Both systems serve conditioned and…

-

Cleanroom HEPA Vacuum Use and Applications

Cleanroom HEPA Vacuum Components and Applications Simply put, every square inch of a cleanroom should be absolutely pristine. Ceiling panels, lighting units, HEPA filtration units, sprinkler heads, walls, glass surfaces, process equipment, piping systems, floors,…

-

CleanPro® Chemotherapy & CSP Cleanroom Installation

This modular, sterile compounding cleanroom is designed for USP 797 and USP 800 compliance, particularly for compounding chemotherapy drugs. Safe handling of sterile compounds requires special considerations: heat-welded floors, anterooms and buffer areas.