Table of Contents

What is A Cleanroom Air Handling Unit (AHU)?

An air handling unit (AHU) is a cornerstone of temperature, humidity, and pressurization within controlled environments. As a part of the HVAC system, it serves as a high powered air processing unit which facilitates movement and conditioning of cleanroom air. 304-grade stainless steel construction houses a filtration system, reverse fan blower, and a cooling element that conditions air for cleanroom input.

Every cleanroom requires a robust air treatment system for the manufacturing of pharmaceuticals, medical devices, semiconductors and healthcare products. Floor space is at a premium, and a dedicated cleanroom HVAC systems must share space with non-critical air systems. Sometimes, the in-house HVAC system is fed directly to a cleanroom fresh air induction. Internal filters and coil systems scrub particles and recondition air which is then fed through HEPA or carbon activated filters before distribution to a cleanroom space.

Air Handling Unit Components

An AHU comprises pre-filters, fan, cooling coils, and a mixing chamber. The internals of the AHU demand the same streamlined surface features found in cleanrooms: a smooth interior finished with no rivets, nuts, bolts, screws, or crevices. Sound attenuators and dampers ensure minimal blower noise and vibration.

Load Bearing Cleanrooms with Roof Mounted AHUs

Modular hardwall cleanrooms allow many configurations that ease space restrictions. A hardwall system is a load bearing structure capable of supporting the full weight of an HVAC system including its AHU. Mezzanines provide space savings and shorten the length air needs to travel on its path from intake to exhaust. For non-weight bearing structures, the AHU is placed on the floor and built within a partition that features the same paneling and wall materials as the cleanroom itself.

Cleanroom Air Filter Placement and Configuration

A pre-filter is placed ahead of a HEPA filter in a cleanroom HVAC system to preserve longevity. Pre-filters help extend the life of HEPA filters by removing particles larger than 1 micron. The AHU fan blades move air with variable frequency drives. Fan controls are either integrated into an automated control system (Fan Filter Control System) or sometimes feature localized control panels. Automated timers and software systems allow lower airflow at times when the cleanroom is not in use, or when activity is minimal. Occupancy sensors enable reduced power consumption when the room is unoccupied.

Does a Cleanroom Air System Run 24/7?

Generally, extended stoppage of a cleanroom air system reduces filters life via “filter loading“. If the air system is shut down completely, particles settle and stagnate within the filter. When turned back on, air pressure impacts particles which have settled in the filter media. The resulting micro tears lead to leaks, reduced performance, and reduced filter life.

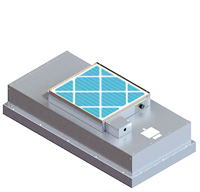

Alternatives to Traditional Air Handling Units - Advantages of Modular Fan Filter Units for Cleanroom Air Filtration

Fan Filter Unit Cleanroom Applications

Fan filter units, also known as integrated blower modules, are a modular cleanroom filtration solution with some advantages over traditional air handling systems. They are applied in both small and large spaces with a cleanliness rating as low as ISO Class 3. Air change rates and cleanliness requirements determine the number of fan filters required. An ISO Class 8 cleanroom ceiling may only require 5-15% of ceiling coverage while an ISO Class 3 or cleaner cleanroom may require 60-100% coverage.

Each filter and housing is customizable in size, air flow rate, and filter media options. This allows further tailoring of cleanroom spaces based on budget and process sensitivity. The most critical process areas may deploy a fan filter unit with ULPA filters. A higher rate of air exchange adds improves particle filtration but is also expands initial and lifetime costs. Modular systems allow upgraded filtration within the most critical areas. Economical fan filter units can be deployed where less critical operations take place.

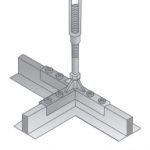

Modular Fan Filter Ceiling Grids

Instead of one centralized system, individual fan filter units are mounted in a housing which is then affixed to a modular ceiling grid system. The filter media includes options for HEPA and ULPA filters for arresting particles and activated carbon filters which eliminate gases, VOCs, and odors.

Fan Filter Unit Installation

These systems are very flexible and adapt as needed. Expanding a cleanroom or increasing air change rates doesn’t require an HVAC contractor to run extra conduit or make dramatic changes to the existing HVAC system. Installation can generally be tackled by small teams without cranes.

Fan Filter Servicing

Each fan filter can be changed out as needed. Unlike a dedicated air handling unit, filter servicing does not require shutting down an entire system. The unit in question can be shut down, while the other units can operate independently so that cleanliness of the space is maintained. Fan filter units are not only easy to service and maintain as needed, but also produce a much lower noise floor when in operation.

These self-contained filters are 99.99% efficient HEPA or 99.9995% efficient ULPA-equipped for a variety of critical applications.

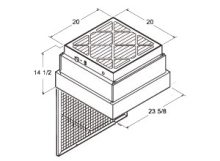

The NCR style fan filter is designed for 90 FPM average face velocity @ and have a rated efficiency of 99.99% @ 0.3 micron or larger. An anodized aluminum frame holds the 53mm media which is protected by a diamond pattern white epoxy coated steel grille. Final filters can be replaced by removing unit from ceiling, placing on a bench, removing and replacing the filter and re-installing the unit in the ceiling.

Reducing Air Handling Noise & Cleanroom Footprint

MicroSound Fan Filter Units include a 99.99% efficient HEPA filter, 30% ASHRAE pleated type prefilter, seismic clip suspension points, a safety switch which disables the unit while servicing. Solid state variable speed control with RFI suppression, allows the airflow to be fine tuned.

Housings are fabricated from steel with a white powder coat finish and include seismic clip suspension points. Final filters are protected with a white epoxy diamond pattern grille and are tested according to accepted procedures as described by the Institute of Environmental Sciences (IEST) and/or ISO standards.

T-Grid Ceilings

T-Grid Ceilings

Learn More

Fan Filter Units

Fan Filter Units (FFU)

Learn More

Replacement Filters

Cleanroom Filters

ShopProduction Automation (that’s us) offers one point of contact for everything cleanroom related. That means everything from fan filter replacements to fully validated and tested cleanroom installations.

Our cleanroom specialists help you identify which components will be best suited for your application with respect to federal and organizational guidelines. Let’s connect you to one of our modular cleanroom solutions, or provide you with a free quote for a custom cleanroom.

Related Posts

-

Cleanroom Fan Filter Replacement

When Should I Replace a Cleanroom Fan Filter? Pre-Filter Replacement Pre-filter media should be replaced every six months and inspected regularly. Pre-filters in gowning rooms should be inspected and replaced more frequently, as un-gowned individuals…

-

CleanPro® Softwall Cleanroom Enclosure

This customer needed to enclose a piece of machinery, and CleanPro® was able to provide a solution.

-

CleanPro® Turnkey Cleanroom Install

CleanPro’s turn-key cleanroom solution provided a one-stop, one-contact result for the initial delivery and on-site installation of walls, ceiling grids, electrical systems, flooring, filters, HVAC, and more.

-

CleanPro® Chemotherapy & CSP Cleanroom Installation

This modular, sterile compounding cleanroom is designed for USP 797 and USP 800 compliance, particularly for compounding chemotherapy drugs. Safe handling of sterile compounds requires special considerations: heat-welded floors, anterooms and buffer areas.

-

Cleanroom Components — Air Filtration, Design, and Other Variables

What are the key determinants of cleanroom components? Learn about different types of cleanroom filtration, wall construction, lights, temperature, humidity and more.

-

CleanPro® Softwall Cleanroom Curtains Installation

Softwall cleanroom curtains, sometimes referred simply as “plastic strips” yield ISO Class 10,000 level particle control with minimal construction. This customer required a custom softwall installation that integrated into their existing building structure CleanPro to…