Table of Contents

What Is Isopropyl Alcohol and How Is It Used?

Isopropyl alcohol (2-propanol), also known as isopropanol or IPA, is the most common and widely used disinfectant within pharmaceutics, hospitals, cleanrooms, and electronics or medical device manufacturing. Different solutions, purity grades, concentrations, and alcohol types yield beneficial cleaning and disinfection properties when applied correctly; or dangerous consequences when used improperly. This post will help you identify key uses, best practices, and proper disinfection with isopropyl alcohol. Likewise you can see our other posts on IPA as a universal cleaner and the importance of high-quality USP IPA.

Why Is 70% the Most Effective Concentration of Isopropyl Alcohol for Disinfection?

Isopropyl alcohol, particularly in solutions between 60% and 90% alcohol with 10 – 40% purified water, is rapidly antimicrobial against bacteria, fungi, and viruses. Once alcohol concentrations drop below 50%, usefulness for disinfection drops sharply. Notably, higher concentrations of alcohol don’t generate more desirable bactericidal, virucidal, or fungicidal properties.

The presence of water is a crucial factor in destroying or inhibiting the growth of pathogenic microorganisms with isopropyl alcohol. Water acts as a catalyst and plays a key role in denaturing the proteins of vegetative cell membranes. 70% IPA solutions penetrate the cell wall more completely which permeates the entire cell, coagulates all proteins, and therefore the microorganism dies. Extra water content slows evaporation, therefore increasing surface contact time and enhancing effectiveness. Isopropyl alcohol concentrations over 91% coagulate proteins instantly. Consequently, a protective layer is created which protects other proteins from further coagulation.

Solutions > 91% IPA do kill bacteria, but sometimes require longer contact times for disinfection, and enable spores to lie in a dormant state without being killed. In this analysis, a 50% isopropyl alcohol solution kills Staphylococcus Aureus in less than 10 seconds (pg. 238), yet a 90% solution with a contact time of over two hours is ineffective. Some disinfectants will kill spores, which are classified as chemical sterilants. So why do higher alcohol solutions yield fewer results for bactericidal and antimicrobial outcomes?

70% Isopropyl Alcohol

4 Gallon Bulk 70% Alcohol In Stock: Yes ☑

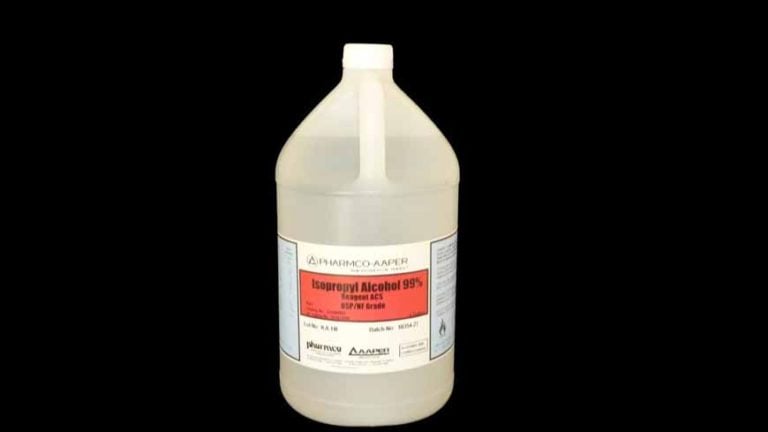

99% Isopropyl Alcohol

4 Gallon Bulk 99% Alcohol

In Stock: Yes ☑

Why Doesn’t Isopropyl Alcohol Kill Bacteria and Fungal Spores?

Is Sterilization with Isopropanol (AKA Isopropyl Alcohol or IPA) Possible?

Proper Uses of Isopropyl Alcohol Require Distinction Between Sanitation, Sterilization, and Disinfection

Terms like disinfection and sterilization are often misunderstood and should not be used interchangeably. The Center for Disease Control (CDC) defines terminology clearly:

Unlike sterilization, disinfection is not sporicidal. A few disinfectants will kill spores with prolonged exposure times (3–12 hours); these are called chemical sterilants. At similar concentrations but with shorter exposure periods (e.g., 20 minutes for 2% glutaraldehyde), these same disinfectants will kill all microorganisms except large numbers of bacterial spores; they are called high-level disinfectants. Antiseptics are germicides applied to living tissue and skin; disinfectants are antimicrobials applied only to inanimate objects. In general, antiseptics are used only on the skin and not for surface disinfection, and disinfectants are not used for skin antisepsis because they can injure skin and other tissues. Virucide, fungicide, bactericide, sporicide, and tuberculocide can kill the type of microorganism identified by the prefix. For example, a bactericide is an agent that kills bacteria.

— CDC

Isopropyl alcohol is excluded from classification as a high-level disinfectant because of its inability to eradicate bacterial spores and hydrophilic viruses such as polio. Its low-level categorization outlines effectiveness for noncritical patient care devices such as blood pressure cuffs. IPA is also commonly applied during cleanroom wipedown for disinfecting tools and packaging that must pass into ultra-clean spaces.

Why Not Use Higher Isopropyl Alcohol (91%+) Concentrations?

70% isopropyl alcohol upholds key requirements for use as a bactericidal in cleanrooms or medical facilities, but also for general purposes. 70% IPA/30% water solutions produce less vapor and odor, therefore reducing risks of toxic fumes or combustion. When isopropyl alcohol reacts with air, light, and oxygen, it forms unstable peroxides which increase the likeliness of explosion, especially when heated with aluminum. IPA volatility increases with storage time and alcohol concentration, especially when exposed to light over multiple years after opening.

70% IPA is less flammable but also offers a more economical price point for general wipe down and large-surface disinfection. Likewise, high-moisture alcohols evaporate slower and increase contact time without becoming immediately dry. If 70% IPA is so effective as both a general-purpose cleaner and disinfectant, why use 99% concentrations?

When Is 99% Isopropyl Alcohol Used?

99% isopropyl alcohol is ideal as a solvent or cleaning agent for industries that produce water sensitive items, therefore rapid evaporation and low water content is favorable. 99% USP IPA provides the lowest presence of water and in some forms is free from denaturants. Computer technicians, medical device manufacturers, printed circuit board manufacturers, and soldering and rework technicians prefer immediate evaporation for work with sensitive devices such as integrated circuit adapters, computer chips, and circuit boards. 99% IPA evaporates cleanly and minimizes residual substances. Rapid evaporation reduces shelf life but is more effective against sticky residues, grease, and grime than 70% concentrations. Because isopropanol is hygroscopic, acetone may yield better grime fighting results for inks or oils.

Is Isopropyl Alcohol Effective Against Fungus and Fungal Spores?

Isopropyl alcohol may be intermittently effective against fungus but it is not effective against fungal spores. Treatment of mold and fungus is generally considered a problem of moisture and humidity. Applying a surface level cleaner may have little or no effect on fungal removal. Bleach and hydrogen peroxide are more commonly associated with remedying mold and fungus outbreaks.

Officially, government organizations are somewhat conflicted on the use of bleach for mold.

The EPA does not recommend bleach.

The CDC recommends bleach as part of a mold remediation effort.

What’s the Difference Between Types of Isopropyl Alcohol?

What Is USP-Grade Isopropyl and What Is It Used For?

The United States Pharmacopeial Convention (USP) is a nonprofit scientific organization that develops and disseminates public quality standards for medicines, food, and supplements. USP-grade isopropyl alcohol certification ensures that both the isopropyl alcohol and any additives are of the highest purity, potency, and accurate concentration. Manufacturing, packaging, and storage must adhere to strict guidelines, and all production facilities must uphold FDA registration and inspection. These specifications improve consistency and safety for industrial, pharmaceutical, flavor & fragrance, or lab use.

What is NSF Grade Isopropyl Alcohol?

What Is Pure Isopropyl Alcohol?

Pure isopropyl alcohol is manufactured and processed without common additives such as denaturants, which make the alcohol unfit for human consumption. Pure isopropyl alcohol is not interchangeable with sterile or USP-grade isopropyl alcohol, but misnomers occur frequently because USP-grade alcohol is always in a pure state.

What Is Industrial Grade Alcohol?

Industrial grade isopropyl alcohol, also referred to as technical grade isopropyl alcohol, is used most commonly for non-critical manufacturing and processing purposes such as removing ionic salts from PCBs, thermal paste from heat sinks and IC packages, or dissolving the organic acids in rosin-based soldering fluxes. It’s an economic option for sanitation of large surface areas, and mitigation of general contaminants such as dust, debris, grease, and adhesives present from other manufacturing processes.

Applications for industrial-grade isopropyl alcohol include:

- Remove ionic salts from PCBs, thermal paste from heatsinks and IC packages, and dissolve the organic acids in rosin-based soldering fluxes.

- Wipe down parts to mitigate general contaminants such as dust and debris present from other manufacturing processes.

- Strip surfaces of grime, grease, paint, & other coatings faster than low-concentration substitutes.

What is Food Grade Alcohol?

The use of isopropyl alcohol for products fit for human consumption is limited. Generally, ethyl alcohol is preferred for consumable products, as it is GRAS (generally regarded as safe). For food-grade products, FCC (Food Chemicals Codex) accreditation establishes acceptable levels of purity and ingredient quality for products intended for human consumption. Isopropyl alcohol use is most commonly found during the preparation of food flavorings, fragrances, fats, oils, colorants, preservatives, sweeteners, and probiotics.

What is Anhydrous Alcohol? Is Anhydrous Alcohol the Same as 99%?

Anhydrous simply means that a solution contains no water, and generally is of 99%+ concentration. Isopropyl alcohol that is 100% free of water is not feasible as it immediately absorbs water after exposure to humid air. High quality anhydrous alcohols produce a purity of +99.96%.

What is Denatured Alcohol?

Denatured alcohol contains an adulterant that renders the solution undrinkable. Sometimes the additive is scented which can reduce the nausea and odors associated with alcohol vapors. While some online stores may market their products as “100% pure denatured isopropyl alcohol”, this is a misnomer. Pure isopropyl alcohol does not contain any denaturants.

70% Denatured Ethanol for Surfaces and Objects

Presaturated ethanol spray (ethyl alcohol) is a common surface decontamination products for pharmaceuticals, healthcare, and medical device manufacturing.

Ethanol is low-level disinfectant considered highly effective against most common viruses.

Clean surfaces, gloves, notebooks, phones, equipment, or any compatible material. Use alcohol with care: may degrade some types of plastics, display surfaces, and enamels.

What Is Sterile Isopropyl Alcohol?

Sterile Isopropyl Alcohol meets the highest standards of purity in aseptic environments. Sterile certification ascertains 0.22-micron filtering, gamma irradiation between 25kGy – 50kGy and compliance of modified AAMI/ANSI/ISO 11137:2006 guidelines. Sterile IPA is packaged in a cleanroom and commonly used within the same environment for wipe down of pass-throughs, cleanroom furniture, laminar flow hoods, cleanroom furniture, and tables or work surfaces. View: MSDS spec sheets for sterile isopropyl alcohol

Is Isopropyl Alcohol the Same as Rubbing Alcohol?

Rubbing alcohol is an antiseptic, which contains as not less than 68% and not more than 72% of isopropyl alcohol. The remaining volume consists of water, with or without suitable stabilizers, perfume oils, and color additives certified by the FDA for use in drugs. The difference between rubbing alcohol and more pure forms of isopropyl alcohol is that rubbing alcohol contains denaturants which make the solution unpalatable for human consumption. Technically, all grades of rubbing alcohol containing 68% -72% isopropyl alcohol fall under the “rubbing alcohol” namesake for household use. Isopropyl alcohol concentrations >91% volume have limited bactericidal efficiency and are less effective for antiseptic use, thus its distinction as “rubbing alcohol” is not warranted and may cause confusion.

In documents cited by the CDC, “rubbing alcohol” is defined as 70% isopropyl alcohol and 30% water.

What Are the Advantages of Presaturated Isopropyl Alcohol Wipes?

Disposable, saturated isopropyl wipes have some technical benefits for cleaning and sanitation. First, the physical mechanism of wiping down a surface does have beneficial impacts on the removal of germs and bacteria.

70% presaturated alcohol wipes allow easier access and apply the appropriate amount of alcohol to the surface without waste or excessive odors.

99% alcohol wipes are frequently used for the production and assembly of electronics components. High purity and low water content alcohol is able to remove resins or pastes without leaving residual water. Because the wipe is manufactured with extremely durable polyesters or nonwoven fabrics, the wipe will not shed particles and lint on to sensitive components.

Finally, prewetted wipes prevent the generation of static energy when wet. Polyesters and non-woven wipes are safer for sensitive electronics when presaturated, as they will dissipate static charge.

Where Can I Buy 70% and 99% Isopropyl Alcohol?

70% Isopropyl Alcohol

4 Gallon Bulk 70% Alcohol In Stock: Yes ☑

99% Isopropyl Alcohol

4 Gallon Bulk 99% Alcohol

In Stock: Yes ☑

For more information, continue with the suggested reading below, or contact us about ordering in bulk, hazmat requirements, or for further questions on best usage and results.

Not everyone requires a bulk purchase of IPA, but when purchased in a 4 pack, you can save roughly 50% per gallon. While you might find some surprisingly cheap IPA deals around the internet, the purity and integrity of the product are essential. Because of PAC’s great relationship with manufacturers, our CleanPro® isopropyl alcohol is both extremely affordable and of highest quality for commercial or lab use.

Related Posts

-

Why 3-Ply Face Masks are Meaningful Alternatives to N95 Masks

How effective are surgical masks and procedural masks as alternatives to N95 masks? Where can I find a reliable supplier of face masks?

-

We Sell The Highest Grade 99% Isopropyl Alcohol By The Gallon. Here's How To Get The Best Price Online.

For any use of isopropyl alcohol, it's essential that the advertised contents reflect the actual reality of the solution. Water to alcohol concentration is a key indicator of efficacy and usefulness of IPA. Quality solvents…

-

Ethanol & Isopropyl Alcohol: Your Questions Answered

The internet's guide to frequently asked questions about Isopropyl alcohol. Find answers to questions about IPA use, sanitizers, and dilution.

-

What is the Shelf Life of Isopropyl Alcohol (IPA)? Does it Expire?

Does Isopropyl Alcohol (IPA) expire and what is the shelf life? How do I store it?

-

The Dangers of Isopropyl Alcohol

Hazards of Isopropyl Alcohol (IPA) As we’ve discussed in a previous post, there are many advantages of using isopropyl alcohol in the manufacturing process because of its low cost, but what we didn’t cover is some of…

-

The Dangers of Isopropyl Alcohol

Hazards of Isopropyl Alcohol (IPA) As we’ve discussed in a previous post, there are many advantages of using isopropyl alcohol in the manufacturing process because of its low cost, but what we didn’t cover is some of…

-

Types of Cleaners | Disinfectants for Industrial, Hospitals, or Medical Devices. How Are They Used?

This article defines, contracts, and compares FDA and EPA requirements for the efficacy of various chemical germicides, sterilants, and disinfectant chemicals.

-

Where to Buy Bulk 3 Ply Face Masks In Stock August 2020

Production Automation Corporation (PAC - that's us) currently has received new inventory of in-stock procedural face masks, ready to ship.

-

IPA as a Universal Cleaner: Advantages & Disadvantages of Isopropanol for PCBs & Electronics

Isopropyl alcohol (IPA) has become a standard in the Electronics Industry for cleaning printed circuit boards (PCBs) as it offers two main advantages: It's cheap It removes ionic contamination (as long as it’s flushed from…

-

How Do I Properly Wipe Down Surfaces in Cleanrooms and Labs?

What are the proper steps for wiping surfaces, biological isolators, and laminar flow cabinets, and excess hazardous drugs?

-

What's the Correct Way to Wipedown a Surface? What's the Advantage of Microfiber Wipes?

What is the proper technique for wipedown and sanitation of surfaces? Why is a microfiber wipe most effective for viruses and infection control?

-

Droplets vs Airborne - Science of Airborne Droplets, Aerosols, Particles, and Face Masks

Aerosols vs Droplets - does COVID-19 spread by aerosols or droplets? Does evidence support airborne coronavirus? 15+ studies on COVID particle size, droplets, ventilation, and face masks.

-

Guide to USP <1072> Disinfectants & Sporicides

USP outlines decontamination practices for critical environments.In this post, we'll outline the types of chemical disinfectants and sterilants used in cleanrooms and laboratories. This includes isopropyl alcohol, bleach, formaldehyde, hydrogen peroxide, and peracetic acid.

82 thoughts on “Why Is 70% Isopropyl Alcohol (IPA) a Better Disinfectant than 99% Isopropanol, and What Is IPA Used For?”

informative article, thank you. when you wrote “isopropanol is hydroscopic…” did you mean hygroscopic?

O the difference a letter can make! Thanks for pointing that out, fixed. 🙂

Didn’t expect to leave a comment, but this article was very interesting. I was planning to use a 91% solution in a spray bottle to clean out my closet of any mold spores but it seems like diluting it to 70% would be more effective and efficient if I’m reading correctly. Thanks for sharing this useful and practical knowledge!

Sorry, I may have misinterpreted what I read since now I see ISP alcohol does not have effective “sporicidal” attributes as I assumed. Or I may just be confusing myself further lol.

Hi Aaron,

Isopropyl alcohol is not effective against fungus or fungal spores. Treatment of mold and fungus is generally considered a problem of moisture and humidity. Applying a surface level cleaner may have little or no effect on fungal removal.

Officially, government organizations are somewhat conflicted on the use of bleach for mold.

The EPA does not recommend bleach.

The CDC recommends bleach as part of a mold remediation effort.

Edited for citation updates.

Hi Muhammad. Here is a safety and specification sheet for pure anhydrous 99.8% isopropyl alcohol. You’ll find that it has only one listed ingredient (isopropyl alcohol known by its chemical name as ISOPROPANOL). Other types of isopropyl alcohol that are not anhydrous contain water for dilution such as 70% IPA, or sometimes additives that render it undrinkable. As for checking the purity, the first step would be contacting the manufacturer or checking chemical labels. A non-scientific test for IPA concentration is how fast the alcohol evaporates. 99.8% IPA evaporates very rapidly once exposed to open air, much faster than those mixed with water. Higher concentrations also have a much more pungent smell.

Does that help answer your question?

Is a good Scotch or Whisky at 40% vol effective in preventing infection?

Hi Bill, scotch and whiskey do have some favorable antiseptic properties. I think you’ll find this article interesting. The problem is that with such a low volume of alcohol, killing something like gas gangrene and other microbes or bacteria would take up to 18 hours of exposure to the ethanol. “For example, a 50 percent ethanol solution needs 15 minutes to kill E. coli bacteria and 45 minutes to kill strep in a “cooked-meat broth,” but just 20 seconds to wipe out pneumonia and strep bacteria on a glass thermometer — presumably a less hospitable environment. Several common bacteria can be killed off in less than two minutes with 70 percent ethanol, and 35 percent will slay some fungi in a minute flat. The stuff also kills many viruses, including HIV, but at low concentrations the job may take hours.” Note: PAC does not recommend using alcohol products as substitute for proper wound care. Using alcohol for wound care may lead to damaged skin tissue.

Do you have the efficacy data sheet for 70% isopropyl alcohol? Do you know where I can find it?

I need the list of microorganisms killed by ISP but can’t find it online.

I would appreciate any help.

Thank you

Hi Gloria, see pg. 205 here: https://pdfs.semanticscholar.org/afa3/834b245ec6289e29840c8003b26470f224a9.pdf

Hi, I am looking for Isopropyl Alcohol of less then 10% concentration,where i can get this? I want this to clean the solar Modules.

Hi Anonymous,

We’ve looked into whether 10% IPA is available from our distributors. It does exist, but is very uncommon in that form, and not something we stock, nor have we seen it anywhere else.

To answer your question, the simplest solution is to dilute a high purity 99% to 10% IPA concentration with high purity water. Essential you’ll be adding 9 parts water, 1 part IPA. For the best outcomes, and to prevent mineral residues from clouding panels, deionized water is ideal a best practice. (Distilled water still contains ionic content that could cloud finishes)

Here’s an example of a 91% solution converted to 99%. Just substitute 91% for 10%:

———————-

(Volume IPA) x (IPA current concentration) /(Final IPA concentration) = (Volume Water) /(Final Water Concentration)

To make 91% IPA from 99% IPA, the problem becomes

Volume IPA x 0.99/0.91 = Volume Water/0.09

Choose a volume for either, for example, let’s make a solution with 10mL IPA

10mL x 0.99/0.91 = volume water/0.09

Solve for Volume Water= 10mL x 0.99x(0.09/0.91) = 0.98mL

Take 10mL of your 99% IPA and add 0.98 mL water to get a final concentration of 91% IPA

———————-

I cannot speak precisely to your application, and recommend that you contact the manufacturer for cleaning recommendations.

If you’re in need of a bulk volume of 10% IPA for a commercial application, give us a call @ 1.888.903.0333. We help businesses source products for unique and uncommon applications everyday.

99% IPA = https://www.gotopac.com/techspray-1610-g4.html

Deionized water: https://www.amazon.com/Ecoxall-Deionized-Water-Gallon-jug/dp/B06ZZ75FGT/

Great information. I use IPA to clean surfaces in my home and at work (desk, keyboard, mouse, phone, etc.) So sick of Clorox/Lysol wipes. IPA is inexpensive and effective.

may i use isopropyl for cleaning of screen printing frame for reclaiming purpose and may i use 70% isopropyl or 99%

which is the best?

Hello Mitch,

I am a certified aromatherapist in search of the proper percentage of isopropyl alcohol to spray into empty bottles for mainly removing dust particles. I order my bottles in bulk and they arrive in a clear plastic bag inside of a box. I currently have a 16 oz.bottle of 91% isopropyl alcohol, remaining 9% being water. From what I have read on your site, this percentage will evaporate very quickly. Therefore, would I be correct to assume it would not leave any residue of water particles in the empty bottle? Cathy B

Hi Anjaneyulu,

Generally a higher concentration of alcohol will provide the best effect for cleaning. You’ll want the least amount of water content possible, hence a 99% solution would be ideal. Sometimes a presaturated lint free IPA is the best option. These are commonly used for removing tough greases oils and grime for stencils used during electronics manufacturing. Low lint wipes won’t rip, tear, or leave behind cloth fibers which would be ideal for cleaning a screen printer. https://www.gotopac.com/products/cleaners/wipes/stencil-cleaning-wipers.html

Hi Cathy,

99% will provide the greatest degree of grit, grime, and dust removal .A 91% will leave behind trace amounts of water, which may cause particles to stick to the sides of the bottle instead of being washed away. (When you add water to dirt, you get sticky mud.) However, a 70% solution may still be ideal if sanitation is required. It’s hard to know what the best solution is for you without knowing what requirements or sensitivities are involved with the application. If you’d like to fill out a contact request or give us a call we can help you identify a solution. https://www.gotopac.com/form-general-rfq

Hello Mitch,

My motive, working with essential oils along with carrier oils combined, is to prevent dust particles and or any residue left in and outside the bottle prior to blending. I am thinking about going with the 99% as you suggested. Of course the blends that I do are strictly for topical and or inhalation use. At this point, I will call your 888 number in the morning to get a quote for the 99% isopropyl alcohol in a large quantity. Thank you very much for your quick response as I appreciate expediting knowledge to others as well.

Best, Cathy Boutin / Aneez Aroma Therapy

Hello Mitch,

I want to know the best of IPA use for electronics part purity at 99% or 70%.

Best regards.

Zaimi

Hi Zaimi,

For electronics you’ll want to use 99% IPA. You’ll also want to use a strong, lint free wipe that won’t shed particles.

https://www.gotopac.com/products/cleaners/wipes/stencil-cleaning-wipers.html

I’ve been doing a lot of searching on IPA and wish I had found this post sooner, very informative. We currently use 99% IPA for cleaning electronic assemblies and purchase our IPA in bulk cases of 12 gallons which we go through within 1 to 1.5 years. We’ve typically not worried about any shelf-life or expiry dates from suppliers since we’ve always assumed IPA was good for long times. However we recently had an audit and the auditor flagged that IPA does have expiry dates that we need to track (though we’ve noticed that some suppliers list an expiry date and some don’t). So I’ve been trying to find out if we need to worry about expiry dates and the bulk of the information I’ve seen basically highlight 2 main concerns as follows:

1) Exposed IPA absorbs moisture over time and therefore the IPA concentration will reduce over time (hence becomes less than 99%).

2) The plastic containers may degrade thus “may lose some small amount leaking through the plastic, or possibly dissolving a little of the plastic into solution”

3) Build up of peroxide.

(Note that I’ve already looked up the link you provided above regarding the feedback from Canadian Centre for Occupational Health and Safety.)

Our IPA is mainly stored in a dark cabinet but we use smaller refill bottles on the Production line for daily use. My question is, given that we go through our IPA within a year or so do we even need to worry about expiry dates?

Hi Dave, good question.

For our USP grade 99% IPA, the shelf life is stated as three years (after manufacture date) before retesting, assuming that it’s stored under favorable conditions. Product integrity is highly susceptible to storage condition.

Unopened containers may last for much longer periods. It would be unlikely that a manufacturer would keep IPA for over three years without using it, as storage space for flammable liquids is generally limited. Beyond that length of time, retesting is recommend to ensure integrity.

We also source other grades of IPA from Pharmco, one of the world’s largest chemical manufacturers. Their statement is as follows:

“Most solvents in their pure state have an indefinite shelf life if stored in unopened containers under proper conditions.” Since many industries require expiration dating as part of their protocols and since Pharmco has only carried out verification to three years, expiration dates for most common solvents is three years from the date of manufacture on the certificate of analysis. This includes almost all solvents in our catalog such as, Acetone, Methanol, Reagent Alcohol, IPA (2-propanol), Ethyl Acetate etc. Only certain solvents have shorter shelf lives. Most but not all specially denatured alcohol formulations have a shelf life of up to five years.”

“For the majority of chemicals, the “retest date” does not mean the product is no longer suitable for use or has “expired”. In most cases a CofA with extended shelf life can be issued by our Quality Assurance Dept. and the material can be used. Retest dates follow common norms in the industry and have been determined based on over 30 years of experience with these products. Please note that there is no official “shelf life” or “stability data” for every product in every package. This is not the responsibility or obligation of the manufacturer but rather the end-user if this type of official data is required.”

https://www.gotopac.com/downloads/dl/file/id/1/cleanpror_cp2991_ipa_usp_grade_99_spec_sheet.pdf

http://www.pharmcoaaper.com/pages/TechLibrary/policy_statements_disclaimers/Shelf%20Life%20Statement%20-%20Solvents.pdf

https://studylib.net/doc/8746738/subject–expiration-dates-for-reagent-chemicals—pharmco

To answer your question:

There’s no data to indicate that IPA would expire or degrade in less than two years, It appears that your storage conditions are acceptable, however, its essential that all solvents in a process chain be labeled and dated, especially flammables. It’s most likely required by law, but also an important part of process controls and reducing any risks to a product during final use.

A) The manufacturer or reseller should provide an analysis, lot code, or data sheet which will include the manufacture date.

B) Your auditor should be able to provide the exact expiration requirements specific to your industry/state/local codes

C) Your organization should identify a best practice for storage duration of IPA appropriate for your facility.

D) Storage containers should be regularly inspected

To summarize, the shelf life of IPA is indefinite, varies by storage conditions, and open to interpretation, but in most cases its either specified by the manufacturer or 3-5 years from the manufacture date, whichever comes first.

Metal containers are available in sizes as small as 5 gallons. This prevents degradation caused by light, plastic, or container damage.

5 Gallon Metal: https://www.gotopac.com/products/cleaners/chemicals/solvents.html?dir=asc&order=position&p_type=628

All of our IPA products provide a MSDS and/or certification sheet as required with the manufacture date. They also contain lot to lot tracking numbers for USP grades which can ease bookkeeping requirements and simplify any questions of source or manufacture date in the case of an inspection. We can also provide discounted pricing on bulk orders.

Feel free to give us a call or send us a chat if you need any help!

So if I spray 70% isopropyl alcohol on my kitchen and bathroom countertops for general cleaning/disinfecting, will it work?

Can you use 99% isopropyl to strip the oils off plants or would 100% be a better option

Can I use 99% IPA that we use in lab and dilute it into 70% IPA and use it as hand sanitizer ?

Bullshit comment in this article regarding Hydrogen Peroxide. The 3% solution kills ALL viruses.

Hi Nima, I’m not sure which statement you are referring to or contesting. There is only one reference here to hydrogen peroxide which points towards its sporicidal efficacy. This article relates specifically to IPA as a disinfectant in different concentrations, it does not serve as an overview (or comparison) of more aggressive sterilants and high-level disinfectants such as PAA, peroxides, glutaraldehyde, ect.

Hi,

There are no dates here, so not sure how recent the post or the comments are, but wanted to ask, with the virus looming and panic buying, is ISP safe in or around rubbing alcohol concentrations to be used as hand sanitiser? Diluted with aloe gel for example?

Thanks.

Dear Mitch Walleser —

Great article. Thanks for all the useful information.

Do you have any insight as to why the major pharmacy companies have gone from selling 90% Isopropyl Alcohol and 70% Isopropyl Alcohol to selling primarily 50% Isopropyl Alcohol?

Given that a minimum concentration of 50% Isopropyl Alcohol is recommended for disinfecting, I would think 70% Isopropyl Alcohol would be preferable.

Thanks for whatever illumination you can provide.

Sincerely,

Argent Flexner

What proportions and % of IPA would you recommend to use for making hand sanitizer solution at home?

Hi! Can you specifically address the best 5 to use to clean surfaces of novel corona virus? I have heard that 80% is required. Also – the required application (spray on – let sit for a minute then wipe – or not wipe, etc.

Best % not best 5 🙂

Mitch,

Maybe this was answered already, but i may have missed it. In a surgical situation what do I use to sterilze the area and the instruments? Grain alcohol 120+ ? To kill all spores? Or is something else better. Is thst overkill sort to speak?

Is 71% Isopropyl alcohol better than 70%? Will it yeid a better result? What about 72% for a better marketing niche?

I only cam find 50% isopropyl alcohol will that be enough to kill the coronavirus the 70%+ is sold out everywhere, is there a way to make the 50% work more effectively against the virus??

Great article..thank you!

Omg wash your hands with soap and water. All these hand sanitizers are not stopping anything. Rubbing causes friction which loosens any microbes. Rinse thoroughly and rinse those microbes down the drain. For the guy with mold or fungus 20 percent bleach will kill that however, I must warn against breathing the fumes so mask yourself. You do not want to breathe any chlorine solution and do not mix other cleaners with bleach it cause a poisonous gas. I have been a nurse for so long I was around before hand sanitzers and gloves. We washed our hands and brought nothing home to our families. Wash before gloves if you use gloves, cause if you have microbes on your hands they grow in a warm, damp dark environment. then wash your hands after you take the gloves off. Please before you let any healthcare provider touch you ask them to wash their hands.

>A 50% isopropyl alcohol solution kills Staphylococcus Aureus in less than 10 seconds (pg. 238), yet a 90% solution with a contact time of over two hours is ineffective.

The source that you link to doesn’t truly say that entirely. In fact, on that same page, it says:

>Powell (1945) reported that S. aureus was killed by a 1-minute exposure at 20C to 50%, 60%, 70%, 80%, and 91% isopropanol solutions, but not by 20%, 30%, and 40% solutions. Other tests showed that the same organisms were killed in 5 minutes by 40% and greater concentrations of isopropanol, but not by the 10%, 20%, or 30% solutions.

It says later on

>Tainter et al. (1944) reported that S. aureus was killed in less than 10 seconds by a 50% aqueous solution of isopropanol. A 90% solution failed to kill the organisms in an exposure of 2 hours

So the same page says 91% isopropanol kills the same bacteria strain in as few as 1 minutes or as many as 2 hours, but only the latter is being presented as absolute fact when it was just one entity’s report and other reports actually seem to contradict it? It gives the impression that 91% isn’t effective at disinfecting when other reports from the exact same source says that it actually is.

NobodyAsked,

Thanks for the comment,

It would be better said that 91% alcohol is *sometimes ineffective*, which makes the statement more representative, but not necessarily more clear.

Have a look at the chart on page 237. As you can see, the bactericidal rate requires longer contact time as the alcohol content increases (on dry threads — no water content). We see that the only effective solutions for things like e coli were between ~60 – 75%. 90% took upwards of 15 minutes (not a meaningful disinfection solution). 99% took between 7 – 24 hours.

If a higher percentage of alcohol dries before it can proliferate bacteria, it’s not considered an adequate disinfectant. That’s not to say 91% alcohol won’t kill bacteria but is just less effective in doing so for most real-world disinfection purposes such as when applied to a rag, cloth, or dry surface.

Hi Nick,

We are a commercial cleaning company and are starting a Detailed Sanitizing Program. We will be sanitizing hard surfaces such as door knobs, handles, workstations, etc. in offices to kill the Coronavirus. We bought a gallon of 99% IPA thinking that would be the best thing to use. Now we know differently — the water allows longer contact and is therefore better. Right?

So, should we dilute the alcohol down to 70%? If so, do we need specific water instead of tap water? Is the dilution ratio say, 7 parts alcohol to 3 parts water (7 oz IPA + 3 oz water)? Can we use the mixture in a pail and just use a cloth to wipe down surfaces? Or should we use spray bottles, then wipe?

We need to keep it simple for our workers.

Sorry, I meant Mitch.

How many hours 70% IPA (Food grade) will work as skin and surface disinfectant? Please, answer as soon as possible.

Can “technical grade” grade alcohol be trusted to use as a disinfectant? Is it true that there are dangerous additives because it’s not USP or NSF tested and labelled?

Hi Mitch Walleser,

In terms of hand sanitizers, which one would you rate better; ethanol based or an IPA based. And if you can please highlight the specific concentrations for each one of them. Is there any data which supports that one ranks over the other.

Looking forward to your response.

Thanks

Hi Vinnn. USP grade would be appropriate for contact with food surfaces(not food), technical grade would disinfect but is more appropriate for industrial purposes than sanitizing surfaces. As a best practice, industrial grade is designed for industrial surfaces and applications. The general use for USP grade alcohol is often for food surface sanitation, or use in pharmaceuticals or other manufacturing operations sensitive to even trace residuals. When you say “dangerous additives” this is referring to the case where somewhere were to use IPA as some type of food or drug additive or food contact surface. Clearly, IPA an any capacity is not fit for human consumption, however there are more pure grades that are used in food related processes, food surfaces (USP/NSF), or as reagents for ingested medicines (FCC grade), or when needed for hypersensitive instruments such as mass spectrometry devices. The key advantage of USP grade is that you know it comes from a reputable source is and verified to have the on-label alcohol content as claimed. You will see USP labeling on many many other types of products.

Can I use 70% isopropyl to disinfect newspapers? How long does it take to become sterile after spraying?

hi,

Can these solution use as spray on Human beings in Tunnel Chamber,while coming into Factory,

Can Isopropyl Alcohol vs ethyl alcohol Spray on Human via Tunnel Chamber while coming into Factory or Office and at what dosage ?

Can I add a general cleaner to alcohol to give it a better smell?

Hi Mitch Walleser,

what is the optimal concentration of Benzalkonium chloride that is effective against SARS-CoV2 ?

please mention the contact time required for the action.

I saw this question from Claudette but didn’t see the answer. This is exactly what I need to know for different reasons. Please advise.

“We are a commercial cleaning company and are starting a Detailed Sanitizing Program. We will be sanitizing hard surfaces such as door knobs, handles, workstations, etc. in offices to kill the Coronavirus. We bought a gallon of 99% IPA thinking that would be the best thing to use. Now we know differently — the water allows longer contact and is therefore better. Right?

So, should we dilute the alcohol down to 70%? If so, do we need specific water instead of tap water? Is the dilution ratio say, 7 parts alcohol to 3 parts water (7 oz IPA + 3 oz water)? Can we use the mixture in a pail and just use a cloth to wipe down surfaces? Or should we use spray bottles, then wipe?

We need to keep it simple for our workers.”

Also, could I leave a bucket of this on the boat dock for kids to use on the boat after sailing a single person boat? Also, is this environmently bad for salt water sea-life in these small doses?

Hi, Im looking for something I can spray on clothing to decontaminate after they have been tried on. I have industrial steamer we use for some but new guidelines for shops are really not very workable unless I can find a solution to being able to put them out after being treated rather than 72 hours later. This will be quite an effect on all retail clothes shops so desperate to find a better and safe solution. As with hand gel the % of alcohol is important to kill covid so by having a spray that is safe to use on garments and skin would help and turn the time and safety of staff handling lots of items being brought back and left to hang around for days. your advice is most welcome, also could it still be used with a clothes steamer or not?

Hello Mitch. I hope that you are having a great day. I had a few questions. My friend wants to manufacture and sell hand sanitizers. We are in Los Angeles County.

1) do we have to have a permit or license using isopropyl alcohol .

A) can we use 99% usp grade.

2)are we able to use our own formulation approved using eucalyptus oil.

3) can we use a residence as our location to manufacture hand sanitizer approved by the FDA

Hello, I’ve been using half and half of 50% alcohol and 91% alcohol to get ~70% alcohol. Should I be using water instead please? If so, please explain why since 50% alcohol has a high water content(?). If water MUST be used, how are people supposed to get “purified” water, can bottled or filtered water be used?

Thanks,

-Clint

For those with questions on hand sanitizer formulations, see FDA guidance here:

Temporary Policy for Preparation of Certain Alcohol-Based Hand Sanitizer Products During the Public Health Emergency (COVID-19) Guidance for Industry

https://www.fda.gov/media/136289/download

Anyone please?

——-~2 weeks ago?————

Hello, I’ve been using half and half of 50% alcohol and 91% alcohol to get ~70% alcohol. Should I be using water instead please? If so, please explain why since 50% alcohol has a high water content(?). If water MUST be used, how are people supposed to get “purified” water, can bottled or filtered water be used?

Thanks,

-Clint

Hi Clint, 50% alcohol contains 50% water (by principle). Indeed, 50% alcohol is lower than ideal alcohol concentration as widely recommended for sanitation purposes.

This video suggests mixing 91% alcohol and 50% alcohol together in the exact same concentration, (1 gallon 91% + 1 gallon 50%) one should arrive at an effective concentration for sanitation purposes, roughly 70.5% alcohol.

https://www.youtube.com/watch?v=JxrMdL_PYC4

As we are not chemists at PAC or in any way a compounding facility of chemicals and substances, it’s not something we can provide direct assistance on. However, the information is widely available on the internet for those who require dilution formulas.

Ok thanks a bunch, I appreciate the info. 😉 So when I run out of 50% and have to use water with 91%, then what about this please: If water MUST be used, how are people supposed to get “purified” water, can bottled or filtered water be used?

Thank you,

-Clint

To purify tap water at home allow to sit for 24 hours to allow certain things (i.e. chlorine) to evaporate and others (i.e. minerals, metals) to settle, next filter (using a coffee filter), then boiling. Filter it through a coffee filter placed inside funnel or tea strainer. Bring the clear water to a rolling boil for 1 minute (at elevations above 6,500 feet, boil for three minutes). Let the boiled water cool before using.

Hi Mitch

I have Isopropyl Alcohol 99% Lab Grade

Can this be used (after diluted) on skin like a rubbing alcohol bought in the store? I’m hoping that is the case and also would like to use it for wiping down surfaces. From what I’ve read 70% would be my best bet for this? Thank you in advance!

Mitch? 😉 “Ok thanks a bunch, I appreciate the info. So when I run out of 50% and have to use water with 91%, then what about this please: If water MUST be used, how are people supposed to get “purified” water, can bottled or filtered water be used?

Thank you,

-Clint”

Dawn, as long as it’s not denatured alcohol, it’s ok. Denatured has ingredients in it that can open up pores and cause your body to absorb it which is of course bad. It also has vapors than can be harmful.

thank you for this article, very helpful and detailed. I have a question, I am using IPA 99% mixed with 30% purified water to sanitize surfaces and my hands, is is safe to wiping away mold from cheese surface while aging the cheese…I am making aged cheese and washing the chese rind with vinegar, sometimes doesn’t help wipe the molds…

thank you in advance, Violet

In 1liter of 99% or 70% iso.pro.alcohol…how much water is needed to add for the use of hand rubbing or using over body surface to disinfect against covid… Perhaps nice presentation…

Pls let me know as early as possible

With regards

Hi Mitch,

Can you give me reference journals/books for the statement of “Isopropyl alcohol, particularly in solutions between 60% and 90% alcohol with 10 – 40% purified water, is rapidly antimicrobial against bacteria, fungi, and viruses.”?

Thank you!

Joanne

Hi Joanne,

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3888844/

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC88911/

https://www.cdc.gov/infectioncontrol/guidelines/disinfection/disinfection-methods/chemical.html

Edit for clarity, IPA works against “some but not all” viruses.

Hello. You’re getting lots of questions now, of course. But I wonder, do the non-water ingredients in hand sanitizers, such as glycerin, propylene glycol, citric acid, etc still allow the proper absorption effect in viruses and bacteria as opposed to water? I know the health organizations seem to recommend around 70% alcohol in these too, but are they only considering that because of the norm with water, or because these substances truly do allow absorption into bacterias’ innards as well as water? And are ones with ethyl alcohol as effective? Thanks.

Hi Mtch,

Does alcohol for hand sanitizer have to say antiseptic on the label? What does that mean?

Violet,

IPA is not designed for food. There are some high purity grades in which IPA is used within the manufacturing process: pharmaceuticals, supplements, ect. A better option might be a high-purity food grade ethanol. (Grain neutral spirit – “everclear”). We like cheese, however we are not familiar with the process and can’t make a recommendation.

Hi Anne,

1. Labeling Requirements – If following FDA guidelines, the label should say Alcohol Antiseptic 80%. FCC Grade ethanol is a high purity alcohol recommended for large scale hand sanitizer production. This is different from general ingredients for surface sanitation (IPA)

Read: Policy for Temporary Compounding of Certain Alcohol-Based Hand Sanitizer Products During the Public Health Emergency Immediately in Effect

2. There are a handful of caveats for what has “antiseptic properties” and what can be sold on the market with on-label claims. Here’s one example, there are certain chemical ingredients which are not allowed for use in alcohol based hand rubs.

INELIGIBLE ACTIVE INGREDIENTS

3. See Section: Ethanol for Hand Sanitizer Production

Hi Samantha, it’s best to read the label carefully. Not every sanitizer is formulated the same. Hand sanitizer is a bit different than surface disinfection, its ethanol, which is recommended at higher % concentration, usually 75% – 85%. It’s widely recognized that ethanol is effective against many viruses.

“Ethanol, the most common alcohol ingredient, appears to be the most effective alcohol against viruses, whereas, propanol is considered to be a better bactericidal alcohol.” https://www.ncbi.nlm.nih.gov/books/NBK513254/

Studies Indicate 70% Ethanol Effective for Disinfection of Many Corona Viruses

Hi Mitch,

I’m based in Belgium, but a Google search brought me to your page.

I would like to find a product to wipe down my smartphone screen once or twice a day. The information on the internet can be very confusing to someone with no knowledge in this field. I know that there are one-use wipes marketed for this purpose, but I find this a terrible waste of material, plus they are quite expensive.

What type of product would you recommend for daily disinfection, with a microfiber cloth for example. Avoiding damage to the screen’s oleophobic layer is my main concern.

Samsung had this to say:

You can also use a disinfectant, such as a hypochlorous acid-based solution (containing 50-80ppm) or an alcohol-based solution (containing more than 70% ethanol or isopropyl alcohol). Do not apply these liquid solutions directly to your device; they should be carefully applied to a microfiber cloth instead.

Thanks in advance.

Jason

Hi Jason, we’ve looked into this. Your screen likely has a cover or screen protector, sometimes its tempered glass cover with an additional ultra-thin layer over the glass itself. So if you have a 3rd party cover / screen protector on your phone, some of these have oleophobic layers, others do not. You might want to check with that manufacturer’s instructions as well.

No matter what, the layer is going to wear off over time. There are many solutions to restore this coating. Are they as effective as the original factory coating? Hard to say.

Alcohol will have some affect on the oleophobic layer over time; a chlorine-based disinfectant seems rather aggressive. The advantage of both of these is that they will not leave residue.

Whatever you apply, certainly use a microfiber wipe.

Comparatively, Apple recommends you use 70 percent isopropyl alcohol wipes to clean iPhones, iPads, and other devices during the current coronavirus pandemic. https://support.apple.com/en-us/HT204172

Whatever the manufacturer recommends, its usually the best practice to stick with that.

Is spraying ISP and letting it evaporate an effective means of sanitizing/disinfecting – As in a fabric face cradle or neck pillow?

Hi Salon Sally,

The best option would be to wash and launder fabrics. I’m not aware of any studies that evaluate the efficacy of isopropyl alcohol on fabrics. A better option might be using some type of washable cover or switching to a non-permeable, impervious face cradle cover. https://www.massagesupplies.com/product/14423/

I hope that helps.

Hi Salon Sally,

One more area where we need to be very carefull during this pandemic is cleaning our Descktops, laptops, iPads. This will actually help us to eradicate the chances of getting infected.

Some of the Best practices are mentioned by apple recommends you use 70 percent isopropyl alcohol wipes to clean iPhones, iPads, and other devices during the current coronavirus pandemic.

https://support.apple.com/en-us/HT204172

How To Clean A MacBook Screen during the current coronavirus pandemic.

Hey! your post is so amazing and quite helpful for me, I hope you will keep doing such posts in future and I am very delightful to read you next post, and I have an another page for you that will definitely helpful for you.

Comments are closed.