3D Printing Fume Extractors for Odors and Particles

Does a HEPA filter capture ultrafine particles (UFPs). What toxins does 3D printing produce? Why should every 3D printer have both a activated carbon and HEPA filter?

Does a HEPA filter capture ultrafine particles (UFPs). What toxins does 3D printing produce? Why should every 3D printer have both a activated carbon and HEPA filter?

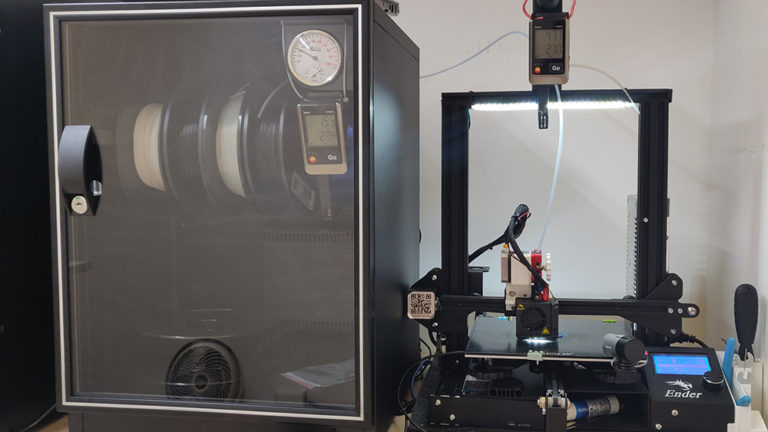

Notably, filaments such as nylon may absorb unacceptable amounts of water in the short period of time they are on the printer. This cabinet provides active feedports for use during prints, and long term storage between cycles. By simply removing your filaments from the factory sealed packaging and placing them into the cabinet, you’ll avoid any baking or saturation completely.

Are you ruining your 3D printing filaments by baking them? What’s the best way to dry FDM and PLA filaments? What about Nylon and PLA?

What’s the easiest and fastest way to clean 3D printed parts with soluble support materials or standard support materials like HIPS and PVA? Here’s how to clean the reaches of 3D printed parts including small geometries, internal cavities, and between build layers so that each part achieves the smoothest possible finish with the least risk of damage caused by handling, scrubbing, or brushing.

Is sterile 3D printing possible? Are 3D printed parts sterile? This comprehensive guide to 3D printing sterile parts provides materials that withstand various sterilization techniques such as autoclaving, heat, ETO, and gamma. Here’s how 3D printing will enhance medical tooling and device manufacturing.