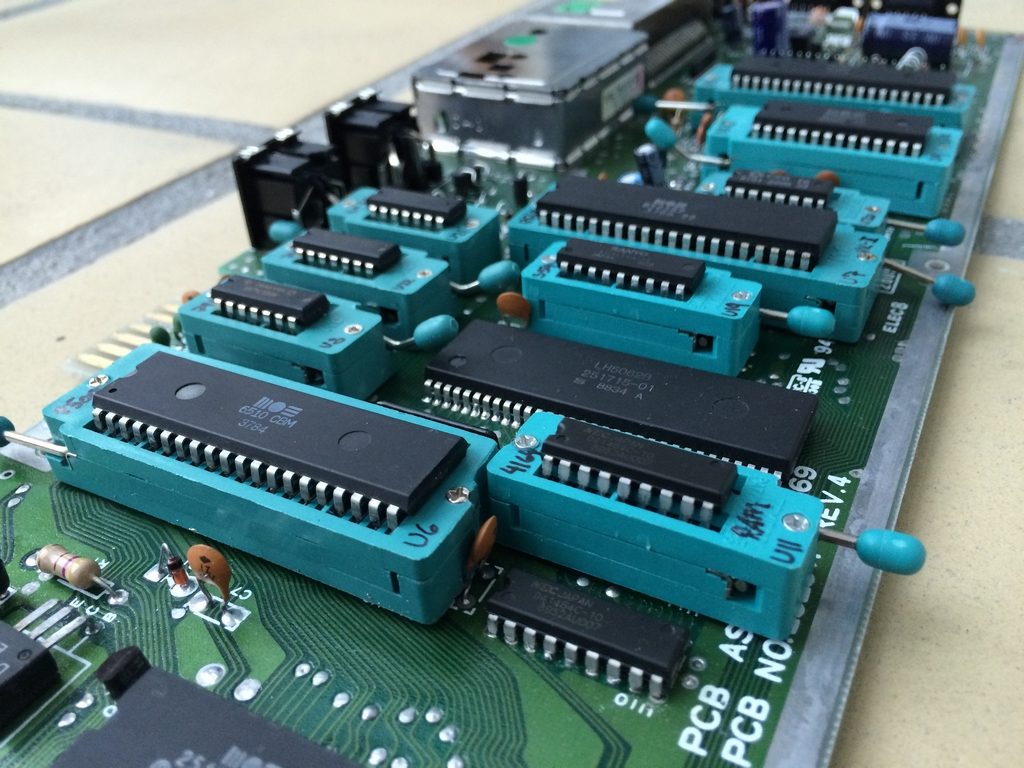

How Do We Get the Most Out of an IC Socket?

The production of new computer processors involves a never-ending demand for faster and more reliable IC (integrated circuit) sockets and adapters. Unlike a permanent connection such as a soldered connection, IC sockets insulate the contacts points and provide mechanical support for a stable, interchangeable connection between components and printed circuit boards (PCB). Predicting the success of new components in end-use requires obtaining performance data before finalizing large-scale production runs for field use. High-performance sockets simplify design, prototyping, and improve product iterations more quickly for bringing products to market within just three weeks. Placing a socket on a PCB with no soldering and little encroachment on nearby components creates a meaningful progression for manufacturers and end-use performance.

Bandwidth

The most crucial factor in selecting a high-performance IC socket is the bandwidth. The best sockets for prototype test applications feature high bandwidth, low resistance, and compliance across extreme temperature ranges. New developments have yielded sockets capable of 75GHz with less than 1dB of insertion loss. Most available network analyzers can only handle up to 40GHz, therefore testing of these sockets requires software to simulate electrical performance. Higher bandwidth allows increased transfer and signals which reduces crashes and improves operation. Verifying the device functionality at a specific frequency is a critical process for test engineers.

“Because the IC has to perform certain functions at specific speed, the signal loss has to be minimal. Since additional socket interface is introduced in the signal loop, either the socket meets bandwidth to pass signal without insertion/return losses or the socket specifics must be de-embedded in the functional verification. Since it is very complex to de-embed specific parameters, a safer solution is to find a socket with higher bandwidth.” – ECNMAG

Excellent Signal Integrity

IC socket adapters offer a quick replacement in the field, but also have limitations. Sockets add an extra interface and increase the chances of bottlenecks and signal degradation when electromechanical signals pass through it. Generally, lesser performing socket adapters introduce noise, heat, and delay into the signal path. High-performance socket adapters improve signal integrity and shield connections from interference with short conductivity length, efficiency insulators, and high-frequency operation. When IC’s require laboratory prototyping or temporary field use, lackluster signal integrity reduces speed, lowers yield, and even causes device failure. Conductive elastomer materials designs unlock the performance of high-I/O applications by improving the stability of the electrical connection with superior insulation and heat dissipation. The length of traditional cantilever spring contact designs, even at a mere contact length of 5.0 mm, cannot meet the rigorous requirements for high-frequency use.

Zero Insertion Force

Smaller, delicate ICs and higher pin counts require the support of insertion and extraction cycles without degradation. Zero Insert Force (ZIF) sockets minimize insertion and extraction force for ease of operation. Prototyping and testing of IC devices requires reliable, user-friendly mechanics with minimal friction. Normally, integrated circuits require an insertion force to achieve friction, grip, and a reliable connection to the IC socket. ZIF design streamlines access, improves repeatability, and adapts easily which ensures optimized connectivity and device integrity. The result is electrical contacts that maintain integrity through the lifecycle of the products for high numbers of changeouts and an extended lifespan without inducing further contact resistance or damage to the circuit board or IC pins.

Small Footprint

A key factor in determining the usability and demand for an IC socket begins while minimizing its use of space. Smaller components empower designers and manufacturers with more design freedom helping them meet increasing demands for smaller, faster, and cheaper components. The demand for ever small devices drives demand for smaller footprints which facilitate easy placement of inductors, resistors, and decoupling capacitors with effective impedance tuning.

Custom Designs

Overall size and method of attachment are crucial to ideal fit and function. Off-the-shelf solutions don’t always fit specific requirements for outdated or rare hardware. Custom designed IC sockets accommodate rare device configurations, odd sizes, and alternate mounting configurations. We help business receive specialty sockets in just three weeks. Over 35 years of business working with the world’s leading IC socket manufacturers provides design expertise and resources for any application. Common custom designs include: upgrading PLCC devices with custom adapters, board-to-board interconnection modules with custom mechanical designs, custom pin receptacles for SAMTEC connectors, right angle DIP receptacles, SMT to Thru-hole devices, and custom socket impedance tuning.

Contact us about a custom socket solutions and get a free quote on custom production runs.

Related Posts

-

Hakko FM-206 High Performance 3-Port Rework Station

The most versatile and compact system for your soldering, desoldering, and hot air rework needs. 3 stations in one! FM-206 3-Port Rework Station The FM-206 rework station's sleek, compact design minimizes loss of bench space…

-

Answering Our FAQs: How to Find the Best Manufacturing Hand Cutting Tools

Are Traditional Steel Tools a Thing of the Past?

-

New Tronex Ceramic Tweezers for High Temperature Applications

New Tronex Ceramic Tweezer Line for High Temperature Use

- Metro Top-Track High Density Shelving

Save space without sacrificing storage! The benefits of using Metro's Top Track High Density Storage: Maximized Storage Capacity: Top-Track can increase the storage capacity of a given area by 30% to 40%. Mobile units are…