1. Ignoring the Need to Wipe on a Regular Basis

To assure quality is maintained in all cleanroom and restricted areas, housekeeping maintenance must be performed daily. Improper cleaning leads to contamination and ultimately loss in end user product quality. Contamination can be broadly categorized into two categories, films and particulates, both of which can cause “killer defects” in miniature circuitry. Contamination in a cleanroom can lead to expensive downtime and increased production costs. Once a cleanroom is brought to standard it must be cleaned and maintained regularly to maintain those standards.

Solution: Each cleanroom will be different and local standards and requirements will vary, but for example, a class 100 cleanroom would require you wipe down your work area once per shift, with a full wipe down of walls, trim, and all other surfaces once weekly in addition to the other various maintenance performed hourly, daily, or weekly. Skipping these regular wipe downs allows particles to collect over time.

2. Using a Flat, Non-Folded Wiper

Failing to fold your wiper is not only wasteful, it risks contamination spread around the surface instead of being removed.

Solution: To maximize each wipers life span fold the wiper into quarter folds, giving multiple clean surfaces to use. Hold the unfolded sides in your hand and group the unfolded edges between our thumb and forefinger. Always discard used wipes according to procedure.

3. Using One Wiper for an Entire Area

Using a single wiper for an entire area is really only cleaning as far as the proper folded wipe method will go, so about eight swipes. After each side of a wiper is used, it is considered contaminated and by continuing to use that wipe it is no longer cleaning the surfaces but spreading contaminates farther.

Swipes should be done in one direction and only overlap 10% to 25%. Turn the wiper so that each new swipe is done with an unused portion of the wiper, once each fold is used the wiper can be refolded so the other side can be used, maximizing the lifespan. Each wiper should clean eight swipes with this folding method, use as many wipes as required for proper contamination removal. Once finished with each wipe dispose of according to site procedures and continue until entire surface has been wiped down.

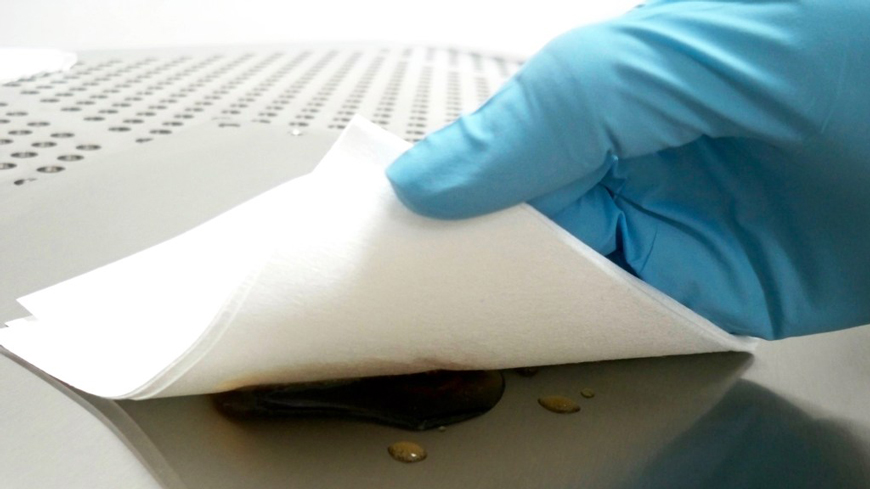

4. Wiping From Dirty/Wet Areas to Clean/Dry Areas

As you can see cleanroom wiping is all about containing and removing contaminants without spreading them to other areas. Spills or other large contaminations should first be dealt with by isolation, using cleanroom approved sorbent materials to contain the mess, followed by a thorough cleaning. When cleaning a cleanroom space it is very important to transition from dirty to clean without re-contaminating clean areas.

Solution: Wipe up and dispose of the bulk of the contaminate, then following the procedures of using a wipe properly, clean from the clean/dry areas into the wet/dirty areas, never the other way around. This way you are drawing the contaminants in and removing them instead of cleaning outwards, spreading the containmates over a wide range of previously clean areas.

5. Wiping in a Circular Motion

Wiping cleanroom surfaces in a circular motion, not surprisingly, spreads particulates and contaminants over clean areas. It won’t matter if you use an entire package of wipers, or how you fold them if a circular technique is used.

Start by pressing down firmly and swiping parallel in one motion across the surface. After each swipe, turn your wiper so the next swipe will be done with a clean side. Keeping track of which areas you have already cleaned and overlapping only about 10% is critical to ensuring that the surface is being completely cleaned and no streaks of particulate are left behind.

6.Using a Dry or Overly Wet Wiper Instead of a Damp One

The point of cleanroom wiping is trapping and removing contaminate and particulate, as we’ve learned. So using a perfectly dry wiper with no moisture will trap some contaminants but for the full benefit, your wiper should be damp.

On the opposite end of the spectrum using a soaking wet wiper will only create a larger mess and leave behind dirty residue over your entire surface requiring that the surface be cleaned again, wasting time and money.

Solution: The type of cleanroom wipers you purchase will depend on many factors, the cleanroom class, the size, company procedures, ect. It may be more cost efficient for a smaller, lower class cleanroom to use dry wipers with a separate cleanser whereas a large scale or highly stringent cleanroom would benefit from a pre-soaked wiper eliminating the need for a second product.

When using a dry wiper with separate cleaner apply the cleaner to the wiper once folded, taking care not to let the cleanser bottle and the wiper come in contact to minimize cross-contamination. Pre-soaked wipes eliminate the need for a second product, and they can be folded into quarters and used immediately.

7. Using a Wiper That is Not Appropriate for the Cleanroom

Cleanrooms come in many shapes and forms depending on the product being produced and industry, state, or government regulations. Cleanrooms are divided into classes, as you can see in the diagram below.

Shop Cleanroom Wipes by ISO Class

| Maximum Particles/m3 | |||||||

|---|---|---|---|---|---|---|---|

| Class | ≥ 0.1 µm | ≥ 0.2 µm | ≥ 0.3 µm | ≥ 0.5 µm | ≥ 1 µm | ≥ 5 µm | FED STD 209E Equivalent |

| ISO 1 | 10 | 2.37 | 1.02 | 0.35 | 0.083 | 0.0029 | |

| ISO 2 | 100 | 23.7 | 10.2 | 3.5 | 0.83 | 0.029 | |

| ISO 3 | 1000 | 237 | 102 | 35 | 8.3 | 0.29 | Class 1 |

| ISO 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | 2.9 | Class 10 |

| ISO 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 | Class 100 |

| ISO 6 | 1.0x106 | 237,000 | 102,000 | 35,200 | 8,320 | 293 | Class 1000 |

| ISO 7 | 1.0x107 | 2.37x106 | 1,020,000 | 352,000 | 83,200 | 2,930 | Class 10,000 |

| ISO 8 | 1.0x108 | 2.37x107 | 1.02x107 | 3,520,000 | 832,000 | 29,300 | Class 100,000 |

| ISO 9 | 1.0x109 | 2.37x108 | 1.02x108 | 35,200,000 | 8,320,000 | 293,000 | Room Air |

Types of Cleanroom Wipes

Each class of cleanroom will have their own specific set of rules and allowances. You can see the particle allowances in the chart above, which means those levels must be maintained to meet cleanroom class requirements. This particle allowance dictates the procedures and products that can be used in the cleanroom so making sure that you are using a wiper that falls in line with acceptable tolerances in crucial. Wipes are manufactured in many ways to accommodate various levels of cleanliness and specific regulations. Here are just a few material examples:

Cleanroom Wipe Edge Cuts

Cleanroom Wipe Materials

- Polyurethane

- Cotton

- Nylon

- Polypropylene

- Polyester/Rayon

- Polyester

- Polyester/Nylon

- Polycellulose

- Cellulose

Cleanroom Wipe Knit and Fabric Types

Solution: Be familiar with your cleanroom class and your company procedures. FDA or USP standards may dictate applicable government regulations or industry standards. Most established cleanrooms have specific product requirements which need pre-purchase approval.

Shop Cleanroom Wipes by Brand

- Berkshire

- Chemtronics

- CleanPro

- Contec

- FG Clean Wipes

- Foamtec

- Kimberly Clark

- TechSpray

- Teknipure

- Texwipe

Need Help Sourcing Cleanroom Products?

We often help facilities specify alternate sources or product substitutes when existing suppliers require large minimum orders or have trouble maintaining stock. In most cases we can provide specific alternatives for your exact recommendation and work directly with manufacturers for bulk resupply, We work directly with manufacturers to

Production Automation (that’s us) helps you select the right product for your cleanroom. Visit our site at www.gotopac.com | cleanroomproducts.com or simply call us at 888.903.0333 Monday through Friday. Email us at [email protected], request a call from a sales specialist, or send us a Live Chat for text based correspondence during your shopping experience.

Related Posts

-

Cleanroom Wipe Use, Protocol, and ISO Class Standards

Cleanroom wipes differ by application, cleanliness, materials, and essential properties. This post addresses cleanroom wipe ISO classes and properties. What's the right wipe for ISO class 5, ISO 6, ISO 7, or ISO 8??

-

New: Texwipe Cleanroom Products

Texwipe offers a variety of dry, pre-saturated, and sterile wipes to meet the strict demands of controlled environments. Texwipe swabs are manufactured to exacting and consistent tolerances with lot coded for traceability and quality control.

-

Polycellulose & Polyester Cleanroom Wipe Supplies

Here's the guide to buying cleanroom wipes that stay on-budget. Differing package sizes, bulk counts, edge types, material options, cloth size, weights, ISO class, substrates, ionic levels…comparing cleanroom wipes is mind numbing. 50% of leading…

-

Aseptic Processing Guidelines - Most Common FDA Inspection Notes

The majority of contamination within aseptic processing cleanrooms involves personnel. Proper application of gowns, hygiene, and a work flow can often eliminate the majority of mix ups and contamination.

-

Gowning Room Design – Guidelines, Anterooms, and ISO Classification

A gowning room has many variables. There is no mathematical formula when determining the features, surfaces, and HVAC requirements best suited for your application. Space requirements, volume of operators, aseptic workflows, material choice, and even…

-

Guide to USP <1072> Disinfectants & Sporicides

USP outlines decontamination practices for critical environments.In this post, we'll outline the types of chemical disinfectants and sterilants used in cleanrooms and laboratories. This includes isopropyl alcohol, bleach, formaldehyde, hydrogen peroxide, and peracetic acid.