OSHA’s recent update to its Hazard Communication Standard changes the requirements when it comes to chemical labeling and mandatory employee training. This means you need to know exactly what the Global Harmonized System (GHS) is and how it affects your business. That’s where Brady and Production Automation comes in. Brady offers the wide variety of products to help your business transition to the new system and PAC has the representatives to answer your questions and guide you through the process.

What is GHS?

GHS = Globally Harmonized System of Classification & Labeling of Chemicals

GHS is a system that’s been created by the United Nations for standardizing the classification and labeling of chemicals throughout the world. In the United States, OSHA is enforcing GHS by adopting it into its Hazard Communication Standard (CFR 1910.1200):

- Defining environmental, physical and health hazards from chemicals

- Communicating these hazards and protective measures on standardized labels and Safety Data Sheets (SDS)

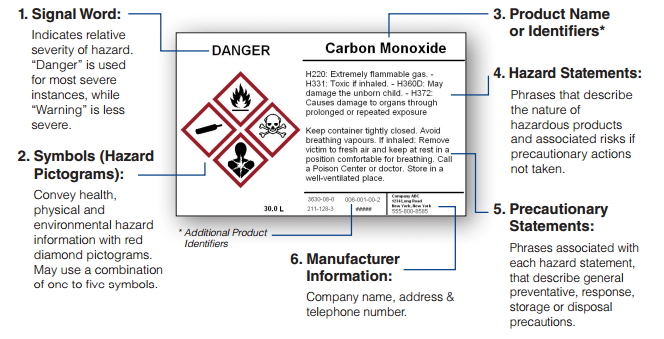

- Under the new GHS format, labels will have 6 elements and SDS sheets have 16 elements.

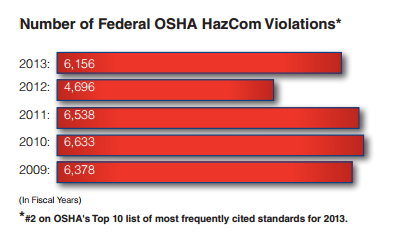

Why Does GHS Matter?

Chemical import/export means big business

Globally, chemical production is greater than $1.7 trillion per year enterprise ($400 billion is in the U.S. alone). Chemical labeling has appeared differently based on different regional requirements. With such an impact on the world economy, it’s critical that the import and export of chemicals be made safe and efficient as possible. The GHS standard globally helps keep workers safe and informed of chemical hazards.

Compliance Timeline and Checklist

December 1, 2013: Employers must train employees on the new label elements and Safety Data Sheet (SDS) format.

- Update Annual Chemical Inventory

- Schedule periodic re-training on pictograms, labels and Safety Data Sheets (SDS). Brady offers both in-person and DVD-based HazCom training solutions.

- Post GHS signs, posters, and hand out wallet cards.

- Separate SDS and Material Safety Data Sheet (MSDS) binders and sheets as part of the management system. This will allow you to re-label chemicals with SDS information and determine which sheers you haven’t received yet.

June 1, 2015: Chemical manufacturers, importers, and distributors reclassify chemicals, send SDS & Labels in GHS format.

- Identify secondary labeling needs and procedures

- Purchase GHS labeling equipment and supplies (Available from Production Automation)

- Implement labeling procedures (create your own labels or order preprinted versions) based on new SDS sheets

- Archive MSDS for determined amount of time (Brady recommends 30 years)

- Re-train on GHS as well as your existing HazCom system (NFPA/HMIS) until full conversion to GHS is complete

December 1, 2015: Distributors send only updated SDS & labels.

- Review and ensure that all MSDS have been converted to SDS format

- Audit all containers for compliance with updated regulations. Establish policy to control improperly labeled containers

June 1, 2016: Employer full compliance deadline.

- Ensure your training policy is in place as internal product changes. Annual training is always recommended.

On-going Compliance Updates

- Note any new hazards identified on SDS and potential Personal Protection Equipment (PPE) changes.

- Ensure your written HazCom program is updated and reflects all internal and external changes.

Label Format and SDS Elements

Label Elements

16 Elements of Safety Data Sheets

OSHA’s updated Hazard Communication Standard requires that the chemical manufacturer, distributor, or importer provide Safety Data Sheets (SDS) for each hazardous chemical to communicate information on these hazards. Each SDS is required to be presented in a consistent format, including the following sections:

- Section 1: Identification Chemical and recommended uses and supplier contact information.

- Section 2: Hazard(s) Identification Hazards of chemical and the appropriate warning information.

- Section 3: Composition/Information of Ingredients Ingredients contained in the products.

- Section 4: First-Aid Measures Initial care that should be given by an untrained responder to an individual exposed to a chemical.

- Section 5: Fire-Fighting Measures Recommendations for fighting a fire caused by the chemical.

- Section 6: Accidental Release Measures Appropriate response to spills, leaks or releases, including containment and cleanup practices.

- Section 7: Handling and Storage Safe handling practices and conditions for safe storage of chemicals.

- Section 8: Exposure Controls/Personal Protection Exposure limits, engineering controls and personal protective measures to minimize worker exposure.

- Section 9: Physical and Chemical Properties Physical and chemical properties associated with the substance or mixture.

- Section 10: Stability and Reactivity Reactivity hazards and stability information.

- Section 11: Toxicology Information Toxicological and health effects information or indicates such data is unavailable.

- Section 12: Ecological Information (non-mandatory) Environmental Impact of the chemical(s) if it were released to the environment.

- Section 13: Disposal Considerations (non-mandatory) Proper disposal practices, recycling or reclamation and safe handling practicing.

- Section 14: Transport Information (non-mandatory) Classification information for shipping and transporting.

- Section 15: Regulatory Information (non-mandatory) Safety, health and environmental regulations specific for the product that is not indicated anywhere else on the SDS.

- Section 16: Other Information When the SDS was prepared or when the last known revision was made.

GHS Pictogram Symbols and Hazard Classes

Training Solutions

OSHA has required all employees who are covered under the 29 CFR 1910. 1200 regulation to complete initial training on the new Hazard Communication Standard updates and the GHS elements. To help you achieve and sustain complete compliance, Brady offers a full suite of training options that Production Automation can help you coordinate and implement. These products range from in-person on-site training from Brady, DVD training programs and refresher programs for annual use, posters, wallet cards, and the printers, labels, and ribbons needed to put these mandates into action.

Related Posts

- Brady PowerMark Sign & Label Maker

Visual Communications command attention, get read and get followed. That's impact. Impact you create every time you create a custom message using the PowerMark Sign & Label Maker from Brady. PowerMark is the industrial sign…

-

View Solutions Inspection Microscopes

Get a close up look at high-quality microscopes, LED magnifiers, and inspection devices from View Solutions.

- Brady ToughStripe Floor Tape

ToughStripe Floor Marking: The Most Durable Floor Marking Tape ToughStripe Floor Marking tape is test-proven to withstand forklift traffic better than any other tape-based floor marking products. That means less tearing, less lifting, and less…

-

Brady BMP51 Label Printer

The BMP51 Label Maker has all the latest features for portable printing on the go: a large display screen, easy-to-use label design apps, fast print speed, and more. You can carry this printer throughout your…

-

Which Portable Brady Printer is Right For You?

BMP21-PLUS Label Printer BMP41 Label Printer BMP51 Label Maker BMP53 Label Maker BMP61 Label Printer BMP71 Label Printer Print Resolution 203 dpi 300 dpi 300 dpi 300 dpi 300 dpi 300 dpi Print Width 0.75"…

- Brady PowerMark Sign & Label Maker

Visual Communications command attention, get read and get followed. That's impact. Impact you create every time you create a custom message using the PowerMark Sign & Label Maker from Brady. PowerMark is the industrial sign…

1 thought on “Globally Harmonized System Solutions from Brady”

The accent is on employee training that will improve hazard communication and make them informed so as to read, interpret and understand data sheets as well as safety labels. Employers benefit by applying safety leadership methods such as a plan to reduce accidents at workplaces and motivate employees to take to the new system (icsds.com)