Table of Contents

Why Do I Need a Switchboard Mat?

According to Occupational Safety and Health Administration (OSHA), there are 350 reported cases of electricity-related injuries that occur in the industrial workplace every year. Exposure to high voltage machinery and equipment are considered hazardous and life-threatening. However, safety measures and requirements were implemented to protect employees’ well-being. OSHA requires employers to maintain a safer environment for their workers who are frequently exposed to hazardous electrical sources.

“No employer shall permit an employee to work in such proximity to any part of an electric power circuit that the employee could contact the electric power circuit in the course of work, unless the employee is protected against electric shock by deenergizing the circuit and grounding it or by guarding it effectively by insulation or other means.”

OSHA Standard 1926.416

Dangerous effects from high voltage can include:

- Ventricular fibrillation is a potentially fatal condition where the heart muscle quivers rather than beats, eliminating blood flow and causing death.

- Cardiac asystole means that the heart stops beating. Combined with with ventricular fibrillation, this constitutes cardiac arrest.

- Respiratory arrest, defined as “the cessation of normal respiration due to the failure of the lungs to contract effectively.”

- Radio frequency burns if radio or microwave frequencies are used.

- Burns from arc flash and resistive heating of body tissues.

Arc flash, or arc blast is a type of electrical explosion that results from a low impedance connection to ground or another voltage phase in an electrical system. In an arc flash incident, enormous amounts of concentrated energy explodes outward from electrical equipment. Five to ten arc flash explosions occur in electrical equipment every day in the United States. The explosion from arc flash can create pressure waves strong enough to damage hearing, fracture ribs, collapse lungs, and knock workers off their feet.

How Does Switchboard Matting Make You Safer?

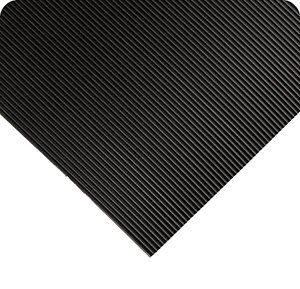

Using non-conductive switchboard matting around electrical equipment can save lives by protecting workers from the deadly shocks that high-voltage equipment can produce.

Switchboard matting works by preventing the worker from being grounded, therefore eliminating the possibility of electrical shock. The mats quickly draw the static off workers before they touch susceptible equipment. Non-conductive mats disperse the static electricity much quicker than static dissipative mats, making them an essential choice for using around high voltage equipment.

The thickness of a switchboard mat affects the amount of voltage it can insulate workers from. Production Automation offers switchboard mats that can insulate up to 30,000 volts. Using a mat in an area where voltage could exceed the mat limits gives a false sense of security for workers and can unduly expose them to injuries or fatalities.

What Do Different Switchboard Mat Standards Mean?

There are two standards that are commonly used in switchboard matting: ANSI/ASTM D178-01, an industry standard, and MIL-15562-G, a military standard.

ANSI/ASTM D178-01

ANSI/ASTM D178-01 is an industry standard, which further classifies switchboard mats by Type and Class. The Type indicates the compound used to manufacture the mat.

- Type I switchboard mats are made of any elastomer or combination of elastomer compounds, properly vulcanized.

- Type II switchboard mats are made of any elastomer or combination of elastomeric compounds with additional properties, including ozone resistance, flame resistance, and oil resistance.

The ANSI/ASTM D178-01 Class indicates the dielectric strength of the mat.

- Class 1 switchboard mats have a Recommended Maximum Use Voltage of 7,500 VAC.

- Class 2 switchboard mats have a Recommended Maximum Use Voltage of 17,000 VAC.

- Class 3 switchboard mats have a Recommended Maximum Use Voltage of 26,500 VAC.

MIL-15562-G

MIL-15562-G is a military standard approved by the Department of the Navy and Department of Defense. The maximum recommended voltage set by this standard is 3,000 VAC. It classifies switchboard mats by the following Types:

- Type I marbleized switchboard mats are designed for permanent installation. Smooth surfaces can be seamed together to create full, custom sized switchboard flooring.

- Type II switchboard mats are fire-retardant, and are designed cover a single work area or piece of machinery.

- Type III switchboard mats are fire-retardant, slip-resistant, and are designed cover a single work area or piece of machinery.

Ensuring that you have the right switchboard matting in place is crucial to the safety of you and your employees. The industry experts at Production Automation can help you understand which mat is right for you, and guide you to a solution that fits your budget. Visit our website to get started.

Related Posts

-

New: Rhino Anti-Fatigue Mats

Search Rhino antifigue mats for dry and wet areas. Mats have chemical, abrasion and grease resitance features. Get free shipping on orders over $100. Find the most popular anti-fatigue mats for standing, kitchens, assembly lines,…

-

Flooring or Matting?

So...flooring or matting? Both improve performance and keep you refreshed, but which one is right for you? Ergonomic FlooringModular, interlocking tiles that can create a floor above a floor. Think in terms of wall…

-

Ergomat 101 - A Summary of Ergomat Anti-Fatigue Matting

There are so many mats on the market, why are Ergomats still the best anti-fatigue and ergonomic mat in the world.?

-

Hog Heaven III Anti-Fatigue Mats | Modular Mats

Select interconnecting Hog Heaven tiles and end pieces for outstanding anti-fatigue qualities in dry areas. The wedge locking system allows for unlimited configuration on walkways or assembly lines for increased grip, electrical conductivity, and weld-safe…

-

Do Standing Desk Anti-Fatigue Mats Really Make A Difference?

Do anti-fatigue mats work and will they really improve joint, back, and leg pain?

-

The Science of Standing

The Circulatory System An expanding body of research exists which addresses standing work positions and the potential damage. The general conclusion of this research is that floor mats are an important element in injury prevention…