Many electronic circuit board assemblies contain both active and passive components; some of these components, particularly semiconductors, may be sensitive to damage from static electricity, while some other components may not be. Still, where one static sensitive device is included in a circuit, the whole circuit assembly should be treated as static sensitive. The purpose of this tutorial is to introduce a few of the many sources of static electricity, and the effect of electrostatic fields on static sensitive electronic components.

ESD for Semiconductor Integrated Circuit (IC) Technology

Advances in the semiconductor integrated circuit (IC) technology over the last several decades has lead to microelectronic devices that are smaller, faster, and cheaper to produce than ever before. Yet, as each new device shrinks in size, we’re also seeing higher circuit density, increases in clock speeds and lower requirements to operate them. Semiconductors and the processes to manufacture them have evolved drastically since the invention of the first bipolar transistors and diodes. With the advent of the high tech IC used widely today, such as complementary metal oxide semiconductors (CMOS) integrated circuits, silicon circuit chips have become so small that they are necessarily manufactured with processes and materials which make the devices sensitive to the invisible forces and forces and effects of static electricity.

While some amount of static electricity is always surrounding us, the amount of static electricity in our environment is highest on days of low humidity. Static electricity is generated by friction on carpets, tile flooring, clothing, hair, fabrics, plastics, rubber, adhesive tapes, ect. The friction of moving air alone will charge suspended dust particles and cause the build-up of static electrical charges on people and objects in our environment.

ESD for Furniture, Tools and Worksurfaces

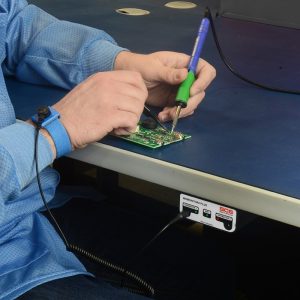

The build-up of static charges on furniture, tools, work surfaces, and objects all around us makes it impractical to avoid or control static electricity without taking special measures. Grounded anti static work mats, wrist straps, and heel grounders provide the means for the controlled discharge of electrostatic charges. Grounded mats and antistatic straps also stop static damage by preventing the build-up of electrostatic charges and fields. Mats and straps are the most common and affordable tools used to deal with static electricity in a work environment. At very minimum, professionals or hobbyists who work with static sensitive components or materials should use these static protection items.

Walking Generation of Static Electricity

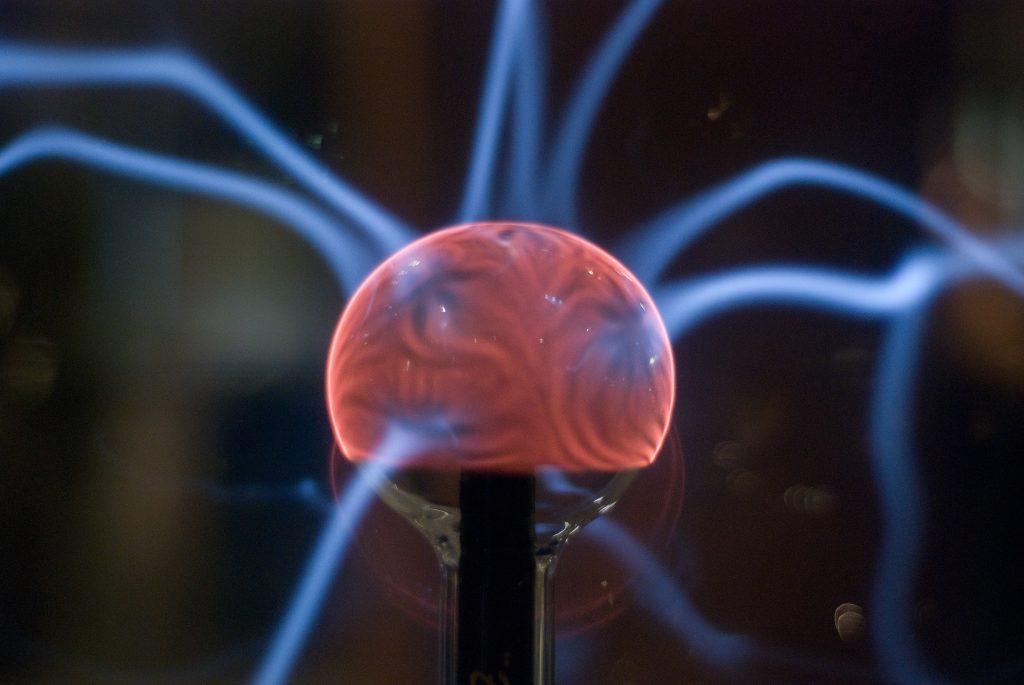

The simple act of walking can generate large static charges that will build up and be stored on our clothing. On a dry day, we can easily generate and carry 40,000 volts of static around with us on our clothes. To some, it may sound incredible that such a high voltage doesn’t kill. The high “static” voltage doesn’t seriously harm us because the amount of stored electric current in a static electric discharge is very low. Because of this very low current, it takes a minimum static charge of about 20,000 volts just to begin to feel the discharge “zap” on the tip of your finger when touching a doorknob for example. It’s only possible to see that little discharge spark at the tip of your finger when the static voltage begins to approach about 40,000 volts.

Read More: How ESD Flooring Principle Go Bad

(DON’T confuse static voltage with other high voltage power sources which CAN provide enough current to harm or kill you, such as AC wall outlets, step-up transformers, and other power source equipment. The danger of high voltage “power sources” must always be respected.)

A crucial point to understand when working with static sensitive electronics such as CMOS semiconductors is that it’s not even necessary to touch an IC in order for static discharge to damage an IC chip. This is because the static electricity we carry on our clothing generates an electrostatic “field” around our bodies that can extend outward up to several feet surrounding us in all directions. Exactly how far an electrostatic field may extend around us or any other source of static charge depends on the static voltage level of the source of the static charge. The strength of the invisible field can be measured with an electrostatic field meter, and this static field strength increases as the source of static charge is approached.

CMOS Devices – ESD Considerations

When unprotected CMOS devices are exposed to a strong electrostatic field, the ultra tiny and thin oxide insulating barriers embedded within the chip circuitry are overcome by the high static voltage potentials. To explain it another way, the thin insulating barriers between the conductive portions inside the IC become unable to resist the flow of static current through or around them. At that critical break down point, a small static current will break through an insulating layer between two or more conductors within the silicon. This totally unseen “short circuit” burst of static discharge current may last only a microsecond, but it will leave behind microscopic holes or paths where it burned through the oxide insulator. In fact, many such static damage events may occur at the weakest points within the IC oxide layers, from a single exposure to a strong electrostatic field.

IC Circuitry

If this damage occurs especially at a critical spot in the IC circuitry, the chip is left with a permanent (and un-designed) opening in the insulation layer between two or more adjacent conductors within the IC. The unseen damage event typically goes unnoticed until normal power is applied to the circuitry, when the normal higher circuit power currents may easily leak through the new “holes” in the insulator. This undesired “short circuit” path permanently alters the IC circuitry, essentially altering the circuit design at random and potentially rendering the circuit partially or completely non-functional.

Even if the static damage event is unknown and initially undetected, and the IC appears to function normally for awhile, it will likely continue to function for only a limited time and the normal lifespan of the IC will be greatly reduced. While the normal circuit power is turned on, some amount of leakage current will be exchanged between conductors through the hole damage in the insulator layer existing between them. At first, the leakage may be very small, and may not seem to affect the operation of the circuit but through a process known as “electro-migration”, the electrons leaking through the insulator barrier will slowly pull some of the conductor material (atoms) through the hole damage in the insulator. These conductor atoms will be deposited on the inside surface of the hole through the insulator. If this electro-migration process were watched through a microscope over time, the conductors in the IC would appear to “grow” together through the hole damage in the insulator. Over time, the electro-migration growth of these conductors through the damaged insulator will further decrease the resistance of the insulator, causing an even further increase in the amount of leakage current, thus further increasing the electro-migration between the conductors. This cycle of damage continues and accelerates until a critical un-designed short circuit is effectively created through the oxide insulator barrier, and the IC will cease to function normally, or may suddenly and completely stop functioning altogether.

To a hobbyist of handyman building or repairing an electronic egg timer, the worries of damage caused by static electricity may not seem to be a very serious concern (if they like to do a lot of preventable, unnecessary and repetitive troubleshooting and repairs). But for commercial electronics manufacturers and professionals, static electricity damage can have huge consequences if their product is part of a medical life support instrument, a military weapon system, computers, cell phones, commercial appliance, or anything else where the highest possible degree of reliability is demanded and expected by the consumer.

Ordnance and Munitions

Static electrical discharges can be a major concern for industries outside the field of electronics as well. For businesses that deal with flammable chemicals, natural gas, fireworks or pyrotechnics, spray painting, or anything else involving explosive dust or fumes, a static discharge spark in the wrong place at the wrong time can mean disaster.

If you or your company have reasons to be concerned about preventing damage caused by static electricity, a small amount of money, time and effort invested in doing so is very worthwhile. The small investment will more than pay for itself in the long run.

Production Automation carries a wide variety of ESD products for all aspects of managing static; from wrist straps and work mats to ionizing bars and blowers. Our knowledgeable sales staff can address all types of problems and present solutions that will work for you and your budget.

You can view our ESD products here, or contact us at 888-903-0333 or [email protected] to speak with an ESD solutions expert. Visit our website at www.gotopac.com and view all of our products or request a quote.

Get Help from a Static Control Specialist

No facility is one-in-the-same. Demand continually grows for a greater degree of product choices with in-stock availability. How can we help?

Production Automation (PAC) is recognized as an ESD specialized organization by enterprises across the US and Latin America. That’s because we directly support each of our ESD product lines from its original invoice to final delivery, including on-site satisfaction, returns, and warranties.

We provide authentic, manufacturer direct static control equipment for general and critical environments including garments, packaging, workstations, flooring, furniture, and test devices.

Ask our static control experts for help with product selection for ANSI/ESD & ESDA standards.

Related Posts

-

Do You Need an ESD Worksurface Mat if Your Workstation Has ESD Laminate?

Answers to Common ESD Questions Such As When Do You Need an ESD Wrist Strap?

-

Do You Need an ESD Chair if You Have an ESD Floormat?

An ESD chair is recommended even when an ESD floor or floormat is in use. The user removing their feet from the floor could cause static generation and discharge. A combination of ESD flooring and…

-

Is Linoleum Flooring Conductive or Anti-Static?

Genuine linoleum is a 100% biodegradable material composed of linseed oil, pine resin, cork, wood, pigment, and limestone. Depending on material construction, it is known to have antistatic properties which mitigate some triboelectric charges that…

-

Static Control Flooring, ESD Epoxy, and Anti Static Primer. How It's Used and Where to Buy It

Static Free Flooring, ESD Tile, and ESD Coatings Updated 9/27/17 As static-sensitive electronic components grow more intricate, so do consumers of static-control flooring. Here are some key points to consider when choosing flooring for home…

-

Do You Need an ESD Chair if You Have an ESD Floormat?

An ESD chair is recommended even when an ESD floor or floormat is in use. The user removing their feet from the floor could cause static generation and discharge. A combination of ESD flooring and…

-

Do You Need an ESD Chair if You Have an ESD Floormat?

An ESD chair is recommended even when an ESD floor or floormat is in use. The user removing their feet from the floor could cause static generation and discharge. A combination of ESD flooring and…

2 thoughts on “ESD Precautions, Always a Good Idea”

thanks to link my pic! 😉

http://www.flickr.com/photos/boarderland

Comments are closed.