Table of Contents

This copyrighted information is licensed for reproduction by EOS/ESD Association, Inc. Click here to view the original article.

In Part Two, Principles of ESD Control – ESD Control Program Development, we introduced six principles of static control and six key elements of ESD program development and implementation. In Part Three, we will cover basic static control procedures and materials that will become part of your ESD control program. First, we review the principles.

Basic Principles Of Static Control

We suggested focusing on just six basic principles in the development and implementation of effective ESD control programs:

- Design in protection by designing products and assemblies to be as robust as reasonable from the effects of ESD.

- Define the level of control needed in your environment.

- Identify and define the electrostatic protected areas (EPAs), the areas in which you will be handling ESD susceptible (ESDS) items.

- Reduce Electrostatic charge generation by reducing and eliminating static generating processes, keeping processes and materials at the same electrostatic potential, and by providing appropriate ground paths to reduce charge generation and accumulation.

- Dissipate and neutralize by grounding, ionization, and the use of conductive and dissipative static control materials.

- Protect products from ESD with proper grounding or shunting and the use of static control packaging and material handling products.

At the facility level, our ESD control efforts concentrate on the last five principles. Here in Part Three, we will concentrate on the primary materials and procedures that reduce electrostatic charge generation, remove charges to ground, and neutralize charges to protect ESDS items.

Identifying The Problem Areas And The Level Of Control

One of the first questions we need to answer is, “How sensitive to ESD are the parts and/or assemblies we are manufacturing or handling?” This information will guide you in determining the various procedures and materials required to control ESD in your environment.

How do you determine the sensitivity of your parts and assemblies or where can you get information about their ESD classification or withstand voltage? A first source would be the manufacturer or supplier of the component itself or by using the part data sheet associated with that component. It is critical that you obtain both Human Body Model (HBM) and Charged Device Model (CDM) ratings. You may also find that you need to have your specific device tested for ESD sensitivity using ANSI/ESDA/JEDEC JS-001 (HBM) and ANSI/ESDA/JEDEC JS-002 (CDM). However, be aware that the correlation between voltages used for device qualification and static voltages measured in the field is weak.

The second question you need to answer is “Which areas of our facility need ESD protection?” This will allow you to define your specific electrostatic protected areas (EPAs), the areas in which you will be handling sensitive parts and the areas in which you will need to implement the ESD control principles. Often you will find that there are more areas that require protection than you originally thought, usually wherever exposed ESDS items are handled. Typical areas requiring ESD protection are shown in Table 1.

| Table 1: Typical Facility Areas Requiring ESD Protection |

|---|

| Receiving |

| Inspection |

| Stores and Warehouses |

| Assembly |

| Test and Inspection |

| Research and Development |

| Packaging |

| Field Service Repair |

| Rework and Repair Center |

| Offices and Laboratories |

| Cleanrooms |

Grounding

Grounding is especially important for effective ESD control. It should be clearly defined, and regularly evaluated.

The equipment grounding conductor provides a path to bring ESD protective materials and personnel to the same electrical potential. All conductors and dissipative materials in the environment, including personnel, must be bonded or electrically connected to a known ground, or create an equipotential balance between all items and personnel. ESD protection can be maintained at a charge or potential above a “zero” voltage ground reference as long as all items in the system are at the same potential. It is important to note that insulators, by definition non-conductors, cannot lose their electrostatic charge by connection to ground.

ESD Association Standard ANSI/ESD S6.1-Grounding recommends a two-step procedure for grounding ESD control items in the EPA.

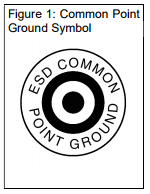

The first step is to ground all components of the workstation and the personnel (worksurfaces, equipment, etc.) to the same electrical ground point, called the “common point ground.” This common point ground is defined as a “system or method for connecting two or more grounding conductors to the same electrical potential.”

This ESD common point ground should be properly identified. ESD Association standard ANSI/ESD S8.1 – Symbols, recommends the use of the symbol in Figure 1 to identify the common point ground.

The second step is to connect the common point ground to the equipment grounding conductor (AC ground) or the third wire (typically green) electrical ground connection. This is the preferred ground connection because all electrical equipment at the workstation is already connected to this ground. Connecting the ESD control materials or equipment to the equipment ground brings all components of the workstation to the same electrical potential. If a soldering iron used to repair an ESDS item were connected to the electrical ground and the surface containing the ESDS item were connected to an auxiliary ground, a difference in electrical potential could exist between the iron and the ESDS item. This difference in potential could cause damage to the item.

Any auxiliary ground (water pipe, building frame, ground stake) present and used at the workstation must be bonded to the equipment grounding conductor to minimize differences in potential between the two grounds. Detailed information on ESD grounding can be found in ESD Association standard ANSI/ESD S6.1, Grounding, and the ESD Handbook ESD TR20.20, and/or CLC/TR 61340-5-2 User guide.

Controlling Static Charge On Personnel And Moving Equipment

People can be one of the prime generators of static electricity. The simple act of walking around or the motions required in repairing a circuit board, can generate several thousand volts of electrostatic charge on the human body. If not properly controlled, this static charge can easily discharge into an ESDS item – a typical HBM discharge. Also, a person can transfer charge to a circuit board or other item making it vulnerable to CDM events in a subsequent process.

Even in highly automated assembly and test processes, people still handle ESDS items, this includes but is not limited to:in the warehouse, in repair, in the lab, in transport. For this reason, ESD control programs place considerable emphasis on controlling electrostatic charge on personnel. Similarly, the movement of mobile equipment (such as carts or trolleys) and other wheeled equipment through the facility also can generate substantial static charges that can transfer to the products being transported on this equipment.

Wrist Straps

Typically, wrist straps are the primary means of grounding personnel and can also offer equipotential bonding in field service repairs. When properly worn and connected to ground, or the equipotential bonding point, a wrist strap keeps the person wearing it at ground potential or the same potential as the object when ground connection cannot be achieved. Because the person and other grounded objects in the work area are at the same potential, there can be no hazardous discharge between them. In addition, static charges are removed from the person to ground and do not accumulate. When personnel are seated and handling exposed ESDS items, they are to be grounded using a wrist strap.

Wrist straps have two major components, the wristband that goes around the person’s wrist and the ground cord that connects the wristband to the common point ground.

Most wrist straps have a current limiting resistor molded into the ground cord on the end that connects to the wristband. Per Ohm’s Law, current is equal to voltage divided by resistance; therefore, adding resistance to the “circuit” of the operator to ground will limit the amount of current flowing through the wrist strap cord. This resistor is most commonly one megohm, rated at least 1/4 watt with a working voltage rating of 250 volts. For personnel safety, if the operator will be exposed to electrical circuits of 250 volts or higher, wrist straps must not be used.

Wrist straps have several failure mechanisms and therefore should be tested on a regular basis. Either daily testing at specific test stations or using a continuous monitor at the workbench is recommended.

Flooring, Floor Mats, Floor Finishes

A second method of grounding personnel is a Flooring/Footwear System achieved by using ESD control flooring systems in conjunction with ESD control footwear. This combination of conductive or dissipative floor materials and footwear provides a safe ground path for the dissipation of electrostatic charge, thus reducing the charge accumulation on personnel. In addition to dissipating charge, some floor materials (and floor finishes) also reduce triboelectric charging.

The use of a Flooring/Footwear System is especially appropriate in those areas where increased personnel mobility is necessary. In addition, floor materials can minimize charge accumulation on chairs, mobile equipment (such as carts and trolleys), lift trucks and other objects that move across the floor. However, those items require dissipative or conductive casters or wheels to make electrical contact with the floor, and components to be electrically connected. When used as the personnel grounding system, the resistance to ground including the person, footwear and floor must be less than 1.0 x 109 (ANSI/ESD STM97.1) and the accumulation body voltage in a standard walking voltage test (ANSI/ESD STM97.2) must be less than 100 volts. Please note that both limits must be met.

Read More: ESD Flooring and Installation Guide

ESD Control Footwear, Casters

Used in combination with ESD control flooring systems, ESD control footwear, casters and wheels provide the necessary electrical contact between the person or object and the flooring system. When working with exposed ESDS items, insulative footwear, casters, or wheels must be avoided as these items prevent static charges from flowing from the body or mobile equipment to ground through the ESD control items.

Clothing

Clothing is a consideration in most EPAs, especially in cleanrooms and very dry environments. Clothing materials, particularly those made of synthetic fabrics, can generate electrostatic charges that may discharge into ESDS items or they may create electrostatic fields that may induce charges. Because clothing usually is electrically insulated or isolated from the body, charges on clothing fabrics are not necessarily dissipated to the skin and then to ground. Static control garments may suppress or otherwise affect an electric field from clothing worn underneath the garment. Per ANSI/ESD S20.20 and the Garment standard ANSI/ESD STM2.1, there are three categories of ESD garment:

- ESD Category 1 garment; a static control garment without being attached to ground. However, without grounding, a charge may accumulate on conductive or dissipative elements of a garment, if present, resulting in a charged source.

- ESD Category 2 garment; a groundable static control garment, when connected to ground, provides a higher level of suppression of the affects of an electric field from clothing worn underneath the garment.

- ESD Category 3 garment; a groundable static control garment system also bonds the skin of the person to an identified ground path. The total system resistance including the person, garment and grounding cord shall be less than 35 megohms.

Read More: What is the ideal material for ESD gloves?

Workstations And Work Surfaces

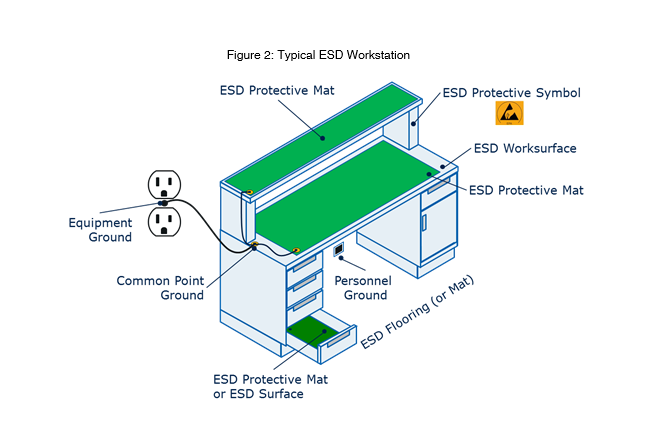

An ESD protective workstation refers to the work area of a single individual that is constructed and equipped with materials and equipment to limit damage to ESDS items. It may be a stand-alone station in a stockroom, warehouse, or assembly area, or in a field location such as a computer bay in commercial aircraft. A workstation also may be located in a controlled area such as a cleanroom. The key ESD control elements comprising most workstations are a static dissipative worksurface, a means of grounding personnel (usually a wrist strap), a common point ground, and appropriate signage and labeling. A typical workstation is shown in Figure 2.

The workstation provides a means for connecting all worksurfaces, fixtures, handling equipment, and grounding devices to a common point ground. In addition, there may be provision for connecting additional personnel grounding devices, equipment, and accessories such as constant or continuous monitors and ionizers.

ESD protective worksurfaces with a resistance to ground of 1.0 x 106 to 1.0 x 109 provide a surface that is at the same electrical potential as other ESD control items at the workstation. They also provide an electrical path to ground for the controlled dissipation of any static charges on materials that contact the surface. The ESD protective worksurface also helps define a specific work area in which ESDS items are to be handled. The ESD protective worksurface is connected to the common point ground.

Read More: ESD Workstation Setup – Grounding & Components

Continuous Or Constant Monitors

Continuous (or constant) monitors are designed to provide ongoing testing of the wrist strap system. While a number of technologies are utilized, the goal remains consistent: electrical connections are tested between the ground point, ground cord, wristband and person’s body while the wearer handles ESDS items. Continuous monitors may also provide a monitoring circuit for the ESD protective worksurface or other equipment connection to the ground reference.

Typical test programs recommend that wrist straps that are used daily should be tested daily. However, if ESDS items are sensitive to a value that a continuous, reliable ground is needed; then continuous monitoring should be considered or even required. Daily wrist strap testing may be omitted if continuous monitoring is used. Users should research the different types of continuous monitoring systems, sensitivities of their ESDS items, and which system will work best for their ESD Control Program.

Production Equipment And Production Aids

Although personnel can be one of the prime generators of electrostatic charge, automated manufacturing and test equipment also can pose an ESD problem. For example, an ESDS item may become charged from sliding down a component part feeder. If the device then contacts the insertion head or another conductive surface, a rapid discharge occurs from the device to the metal object and a CDM event takes place. If charging of the ESDS item cannot be avoided – which is quite often the case in modern assembly lines due to the insulative IC packages – charge stored on packaging materials should be reduced by the use of ionizers. In addition, various production aids such as hand tools, tapes, or solvents can also be concerns when handling exposed ESDS items.

Grounding is the primary means of controlling static charge on equipment and many production aids. Much electrical equipment is required by the National Electrical Code to be connected to the equipment ground (the green wire) in order to carry fault currents. This ground connection also will function for ESD control purposes. All electrical tools and equipment used to process or handle ESDS items require the 3 prong grounded type AC plug. Hand tools that are not electrically powered, i.e., pliers, wire cutters, and tweezers, are usually grounded through the ESD protective worksurface and the grounded person using the conductive/dissipative tools.

Holding fixtures should be made of conductive or static dissipative materials when possible; static dissipative materials are often suggested when very sensitive devices are being handled. A separate ground wire may be required for conductive or dissipative fixtures not in contact with an ESD protective worksurface or handled by a grounded person. For those items that are composed of insulative materials, the use of ionization or application of topical anti stats may be required to control electrostatic charge generation and accumulation of static charges.

Gloves And Finger Cots

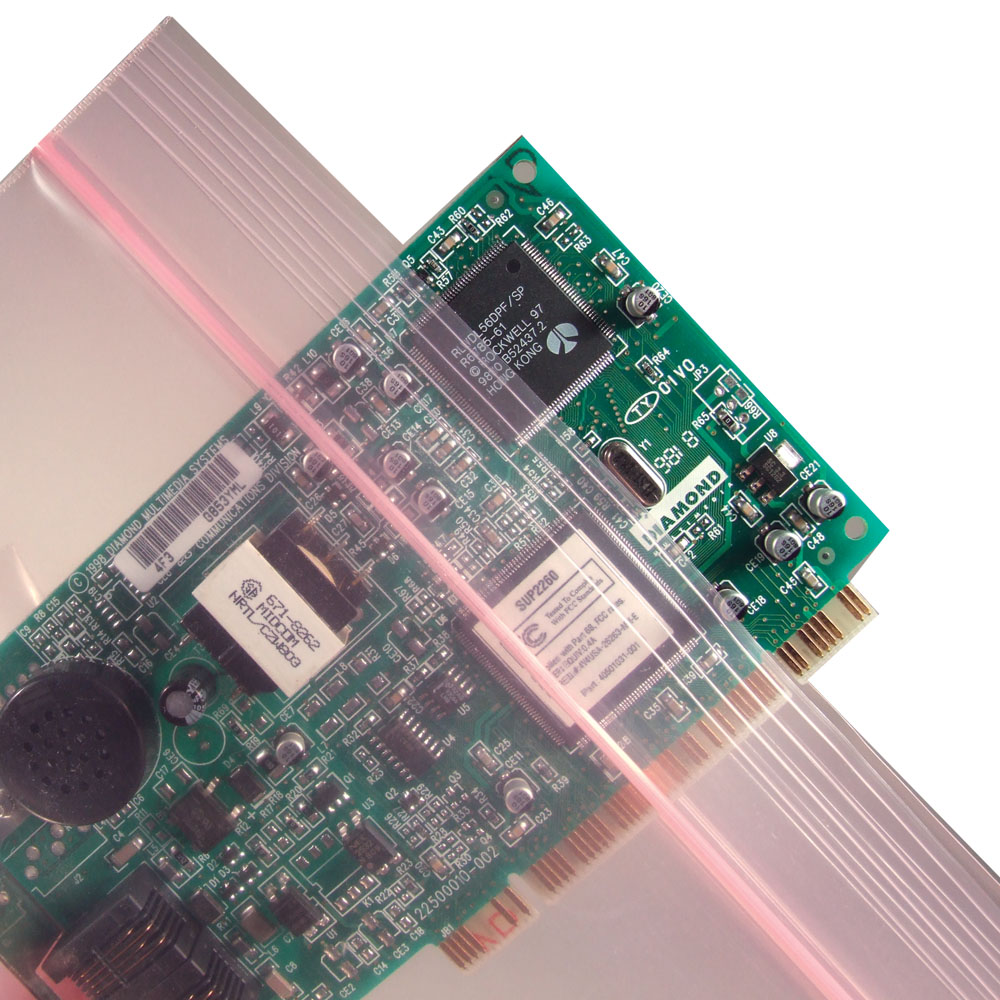

Inside the EPA, packaging and material handling containers are to be low charging and be dissipative or conductive. Outside the EPA packaging and material handling containers are to also have a structure that provides electrostatic discharge shielding.

Direct protection of ESDS items from electrostatic discharge is provided by packaging materials such as shielding bags, corrugated boxes, and rigid or semi-rigid plastic packages. The primary use of these items is to protect the product when it leaves the facility, usually when shipped to a customer. In addition, material handling containers such as tote boxes and other containers primarily provide protection during inter- or intra-facility transport.

When used with ESDS items the main function of packaging and materials handling containers is to limit the possible impact of ESD from triboelectric charge generation, direct discharge, and in some cases electrostatic fields. The initial consideration is to have low charging materials in contact with ESDS items. For example, the low charging property would control triboelectric charge resulting from sliding a board or component into the package or container. A second requirement is that the material can be grounded so the resistance range must be conductive or dissipative. A third property required outside the EPA is to provide protection from direct electrostatic discharges which would make the packaging and material handling container discharge shielding.

Many materials are available that provide all three properties: low charging, resistance, and discharge shielding. The inside of these packaging materials has a low charging layer, but also has an outer layer with a surface resistance conductive or dissipative range. Per the Packaging standard ANSI/ESD S541, a low-charging, conductive or dissipative package is required for packaging or material handling containers within an EPA. Outside the EPA, the packaging or material handling containers must also have the discharge shielding property. Effectiveness, cost and device vulnerability to the various mechanisms need to be balanced in making packaging decisions (see ANSI/ESD S541, the ESD Handbook ESD TR20.20, and/or CLC/TR 61340-5-2 User guide for more detailed information).

Resistance or resistivity measurements help define the material’s ability to provide electrostatic shielding or charge dissipation.

- Electrostatic shielding attenuates electrostatic fields on the surface of a package to prevent a difference in electrical potential from existing inside the package.

- Discharge shielding is provided by materials that have a surface resistance equal to or less than 1 × 103ohm when tested according to ANSI/ESD STM11.11 or a volume resistance of equal to or less than 1 × 103ohm-cm when tested according to the methods of ANSI/ESD STM11.12. In addition, effective shielding may be provided by packaging materials that provide a sufficiently large air gap between the package and the ESDS items. The ability of some packages to provide discharge shielding may be evaluated using ANSI/ESD STM11.31 which measures the energy transferred to the package interior.

- Dissipative materials provide charge dissipation characteristics. These materials have a surface resistance greater than 1 × 104ohm but less than 1 × 1011 ohm when tested according to ANSI/ESD STM11.11 or a volume resistance greater than 1.0 × 105 ohm-cm but less than or equal to 1.0 × 1012 ohm-cm when tested according to the methods of ANSI/ESD STM11.12.

- A material’s low charging properties are not necessarily predicted by its resistance or resistivity.

Ionization

Most static control programs also deal with isolated conductors that are not grounded, or insulating materials (e.g., most common plastics) that cannot be grounded. Topical antistats may provide temporary ability to dissipate static charges under some circumstances.

More frequently, however, air ionization is used to neutralize the static charge on insulated and isolated objects by producing a balanced source of positively and negatively charged ions. Whatever static charge is present on objects in the work environment will be reduced, neutralized by attracting opposite polarity charges from the air. Because it uses only the air that is already present in the work environment, air ionization may be employed even in cleanrooms where chemical sprays and some static dissipative materials are not usable.

Air ionization is one component of a complete ESD control program, and not a substitute for grounding or other methods. Ionizers are used when it is not possible to properly ground everything and as backup to other static control methods. In cleanrooms, air ionization may be one of the few methods of static control available.

See Ionization standard ANSI/ESD STM3.1, ANSI/ESD SP3.3, and ESD TR53 for testing offset voltage (balance) and discharge times of ionizers.

Cleanrooms

While the basic methods of static control discussed here are applicable in most environments, cleanroom manufacturing processes require special considerations.

Many objects integral to the semiconductor manufacturing process (quartz, glass, plastic, and ceramic) are inherently charge generating. Because these materials are insulators, this charge cannot be removed by grounding. Many static control materials contain carbon particles or surfactant additives that sometimes restrict their use in cleanrooms. The need for personnel mobility and the use of cleanroom garments often make the use of wrist straps difficult. In these circumstances, ionization and ESD control flooring/footwear systems become key weapons against a static charge.

Identification

A final element in our ESD control program is the use of appropriate symbols to identify ESDS items, as well as specialty products intended to control ESD. The two most widely accepted symbols for identifying ESDS items or ESD control protective materials as defined in ESD Association Standard ANSI/ESD S8.1 — ESD Awareness Symbols.

The ESD Susceptibility Symbol (Figure 3) consists of a triangle, a reaching hand, and a slash through the reaching hand. The triangle means “caution” and the slash through the reaching hand means “Don’t touch.” Because of its broad usage, the hand in the triangle has become associated with ESD, and the symbol literally translates to “ESD sensitive stuff, don’t touch.”

The ESD Susceptibility Symbol is applied directly to integrated circuits, boards, and assemblies that are ESD susceptible. It indicates that handling or use of this item may result in damage from ESD if proper precautions are not taken. Operators should be grounded prior to handling. If desired, the sensitivity level of the item may be added to the label.

The ESD Protective Symbol (Figure 4) consists of the reaching hand in the triangle. An arc around the triangle replaces the slash. This “umbrella” means protection. The symbol indicates ESD protective material. It is applied to mats, chairs, wrist straps, garments, packaging, and other items that provide ESD protection.

It also may be used on equipment such as hand tools, conveyor belts, or automated handlers that are especially designed or modified to provide ESD control properties (low charging, conductive/dissipative resistance, and/or discharge shielding).

Summary

Effective ESD control programs require a variety of procedures and materials. The ESD coordinator should release and control regularly a list of the specific ESD control products permitted to be used in the facility’s ESD control program. We have provided a brief overview of the most commonly used products. Additional in-depth discussion of individual materials and procedures can be found in publications such as the ESD Handbook (ESD TR20.20) published by the ESD Association or the CLC/TR 61340-5-2 User guide.

Your program is up and running. How do you determine whether it is effective? How do you make sure your employees follow it? In Part Four, we will cover the topics of Auditing and Training.

This copyrighted information is licensed for reproduction by EOS/ESD Association, Inc. Click here to view the original article.

Related Posts

-

Do You Need an ESD Chair if You Have an ESD Floormat?

An ESD chair is recommended even when an ESD floor or floormat is in use. The user removing their feet from the floor could cause static generation and discharge. A combination of ESD flooring and…

-

ESDS Device Sensitivity and Testing: The Fundamentals of Electrostatic Discharge, Part 5

This copyrighted information is licensed for reproduction by EOS/ESD Association, Inc. Click here to view the original article. In Part Two of this series ("Principles of ESD Control – ESD Control Program Development"), we indicated that a…

-

ANSI/ESD Standards: Design, Training, and Safety for Organizations

Today, more than ever, meeting the complex challenge of reducing ESD losses requires more than reliance on faith alone. Users require a way to legitimately evaluate and compare competing brands and types of products. They…

-

An Introduction To ESD: The Fundamentals of Electrostatic Discharge, Part 1

This copyrighted information is licensed for reproduction by EOS/ESD Association, Inc. Click here to view the original article. History & Background Greek scientist, Thales of Miletus mentioned the earliest report of electricity. He found that after amber…

-

Training and Compliance Verification Auditing: The Fundamentals of Electrostatic Discharge, Part 4

This copyrighted information is licensed for reproduction by EOS/ESD Association, Inc. Click here to view the original article. Your static control program is up and running. How do you determine whether it is effective? How do you…

-

ESD Handling Procedures

All personnel in an organization who handle ESD sensitive items (ESDS) are to receive ESD control training. In addition, facilities personnel and those who design products to purchase electronic items should also receive ESD control…